KiCad Nightly Reference Manual

| 本手册正在修订中,以涵盖KiCad的最新稳定发布版本。 它包含一些内容尚未编写完成。 我们希望您能耐心等待我们的志愿技术作者完成这项工作。 同时我们也欢迎新的贡献者加入我们的行列,帮助我们使 KiCad 的文档比以前更好。 |

Copyright

This document is Copyright © 2010-2024 by its contributors as listed below. You may distribute it and/or modify it under the terms of either the GNU General Public License (http://www.gnu.org/licenses/gpl.html), version 3 or later, or the Creative Commons Attribution License (http://creativecommons.org/licenses/by/3.0/), version 3.0 or later.

本指南中的所有商标均属于其合法所有者。

Contributors

Jean-Pierre Charras, Fabrizio Tappero, Wayne Stambaugh, Cirilo Bernardo, Jon Evans, Graham Keeth

翻译人员

Qinghan Hu <[email protected]>, 2023.

taotieren <[email protected]>, 2019-2024.

Feedback

The KiCad project welcomes feedback, bug reports, and suggestions related to the software or its documentation. For more information on how to submit feedback or report an issue, please see the instructions at https://www.kicad.org/help/report-an-issue/

Software and Documentation Version

This user manual is based on KiCad 9.99. Functionality and appearance may be different in other versions of KiCad.

Documentation revision: 54859930.

KiCad PCB 编辑器简介

The KiCad PCB Editor is a PCB layout application distributed as a part of KiCad and available for the following operating systems:

-

Linux

-

Apple macOS

-

Windows

Regardless of the OS, all KiCad files are 100% compatible from one OS to another.

The PCB Editor is an integrated application where all functions of placing footprints, routing tracks, library management, and data transfer to and from the schematic capture software are carried out within the editor itself.

The KiCad PCB Editor is intended to communicate directly with the KiCad Schematic Editor for designing printed circuit boards from schematics without using any intermediate files. It can also import netlist files, which list all the electrical connections, from other packages.

The PCB Editor includes a footprint library editor, which can create and edit footprints and manage libraries. It also integrates the following additional but essential functions needed for modern PCB design software:

-

Design rules check (DRC) for automatic detection of design rule violations such as incorrect and missing connections, copper clearance and minimum width violations, and many other design issues

-

Scriptable design rules for specifying rules with complex constraints and conditions

-

An interactive router with multiple modes of operation (push-and-shove, walkaround, highlight collisions) and support for differential pair routing as well as length and skew tuning

-

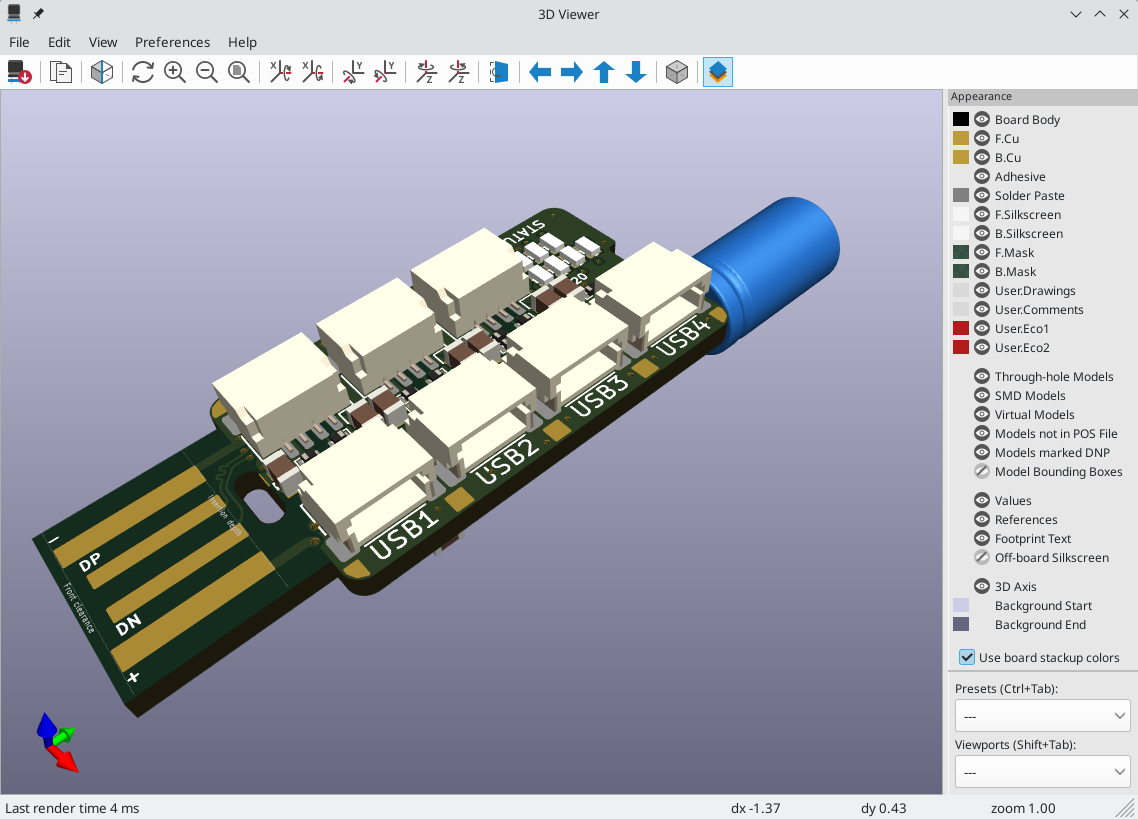

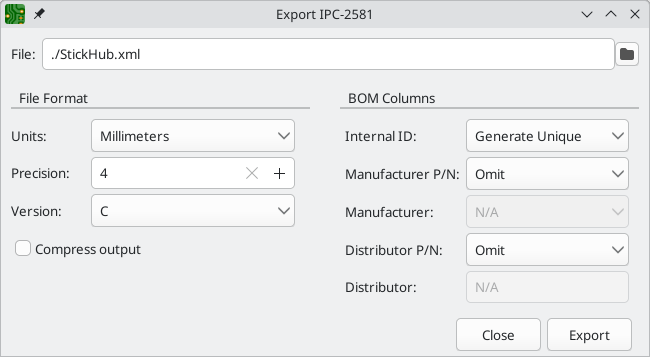

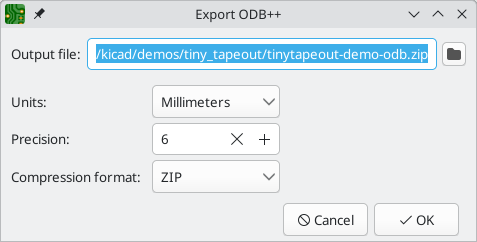

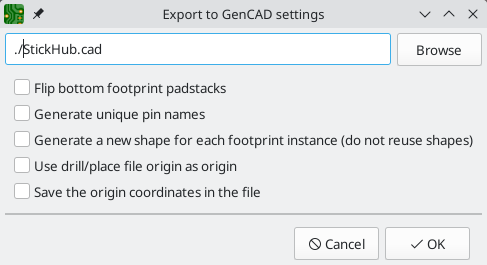

Export of fabrication and plot files in many formats (Gerber, IPC-2581, ODB++, GenCAD, PDF, SVG, and HPGL)

-

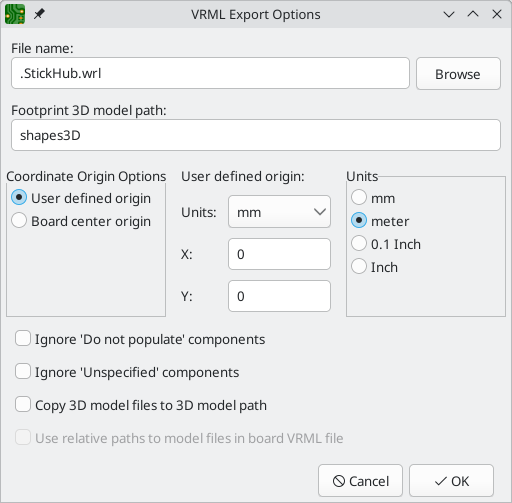

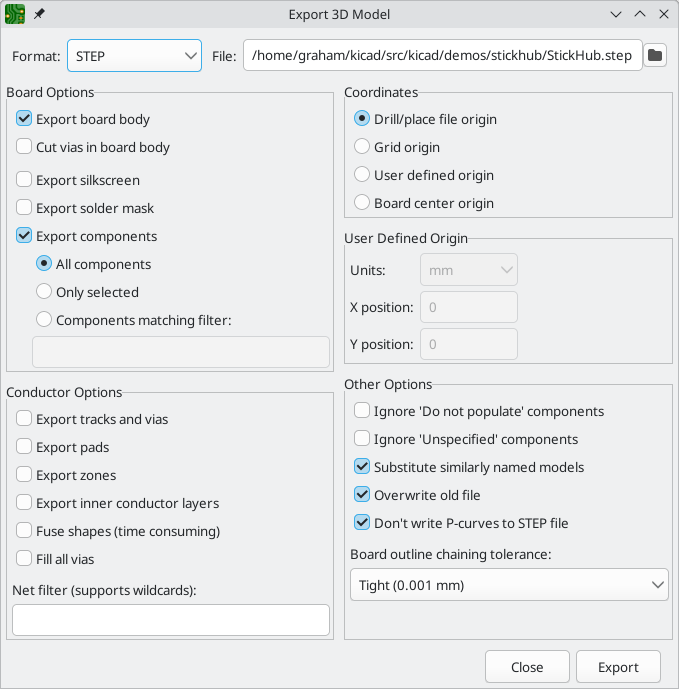

A 3D viewer and 3D model generation in many formats (STEP, GLB, BREP, XAO, PLY, STL, IDF, and VRML)

初始配置

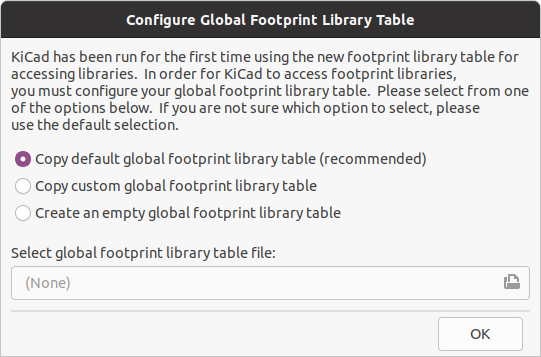

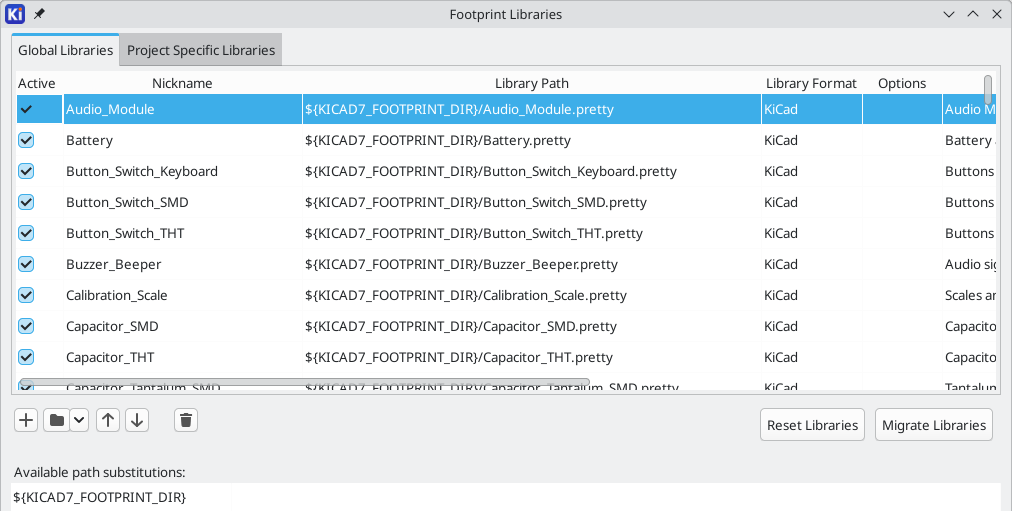

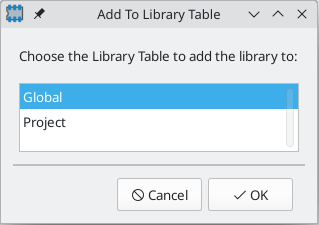

当 PCB 编辑器第一次运行时,如果在 KiCad 配置文件夹中没有找到全局封装表文件 fp-lib-table,那么 KiCad 将询问如何创建这个文件:

第一个选项是推荐的(复制默认的全局封装库表)。默认的封装库表包括所有作为 KiCad 的一部分安装的标准封装库。

如果该选项被禁用,KiCad 无法找到默认的全局封装库表。这可能意味着你没有和 KiCad 一起安装标准封装库,或者它们没有被安装在 KiCad 期望找到的地方。在某些系统中,KiCad 库是作为一个单独的软件包安装的。

-

如果你已经安装了标准的 KiCad 封装库并想使用它们,但第一个选项被禁用,选择第二个选项并浏览到安装 KiCad 库的目录中的

fp-lib-table文件。 -

如果你已经有了一个你想使用的自定义封装库表,选择第二个选项并浏览到你的

fp-lib-table文件。 -

如果你想从头开始构建一个新的封装库表,选择第三个选项。

Footprint library management, including how to re-run this initial configuration, is described in more detail later.

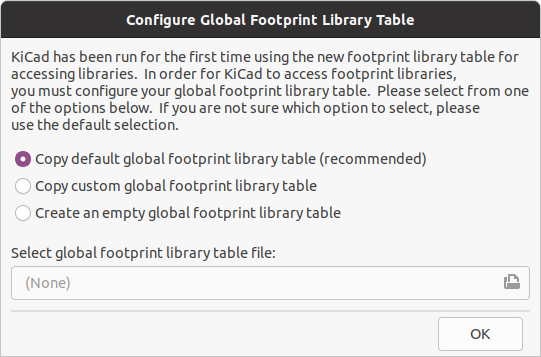

PCB 编辑器的用户界面

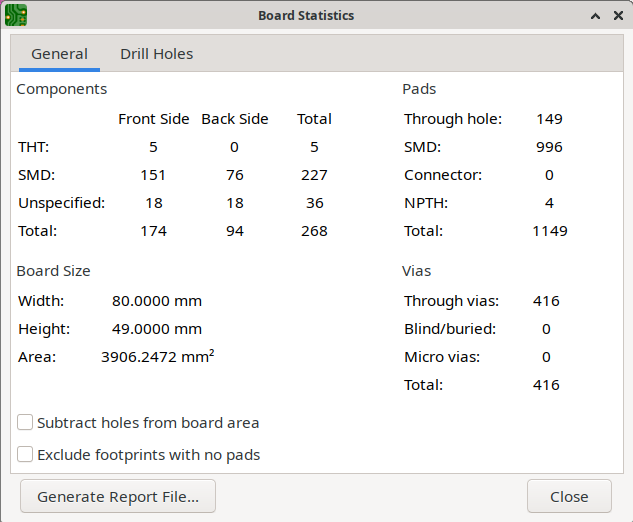

PCB 编辑器的主要用户界面如上图所示,并标明了一些关键元素:

-

顶部工具栏 (文件管理、缩放工具、编辑工具)

-

左侧工具栏 (显示选项)

-

消息面板和状态栏

-

右侧工具栏 (绘图和设计工具)

-

外观面板

-

选择过滤器面板

浏览编辑画布

编辑画布是正在设计的电路板视图。您可以平移和缩放到电路板的不同区域,也可以翻转视图以从底部显示电路板。

默认情况下,用鼠标中键或右键拖动会平移画布视图,滚动鼠标滚轮会放大或缩小视图。 你可以在偏好设置中的鼠标和触摸板部分改变这一行为(详见 配置和定制)。

在顶部的工具栏中,还有其他几个缩放工具可用:

-

放大视口的中心。

放大视口的中心。 -

从视口中心缩小。

从视口中心缩小。 -

缩放以适应绘图页周围的框架。

缩放以适应绘图页周围的框架。 -

缩放以适应绘图页内的对象。

缩放以适应绘图页内的对象。 -

允许你画一个方框来确定缩放的区域。

允许你画一个方框来确定缩放的区域。

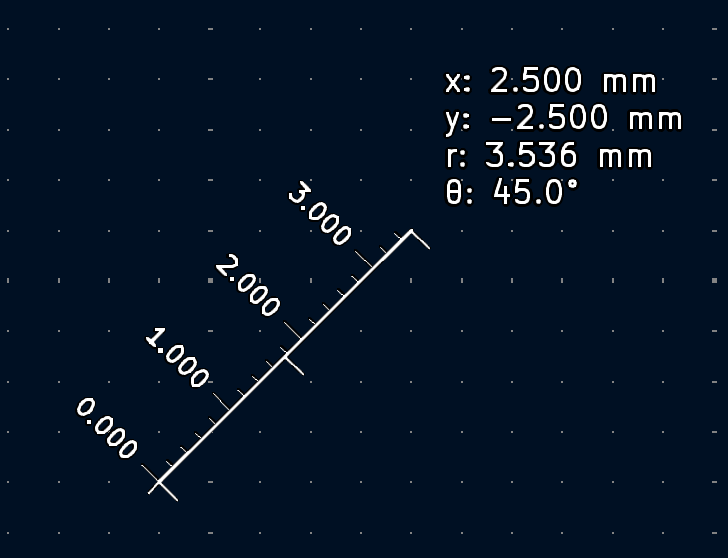

光标的当前位置显示在窗口的底部(X 和 Y),同时显示的还有当前的缩放系数(Z)、光标的相对位置(dx、dy 和 dist)、网格设置和显示单位。

按 Space 可以将相对坐标重置为零。这对于测量两点之间的距离或对齐对象很有用。

快捷键

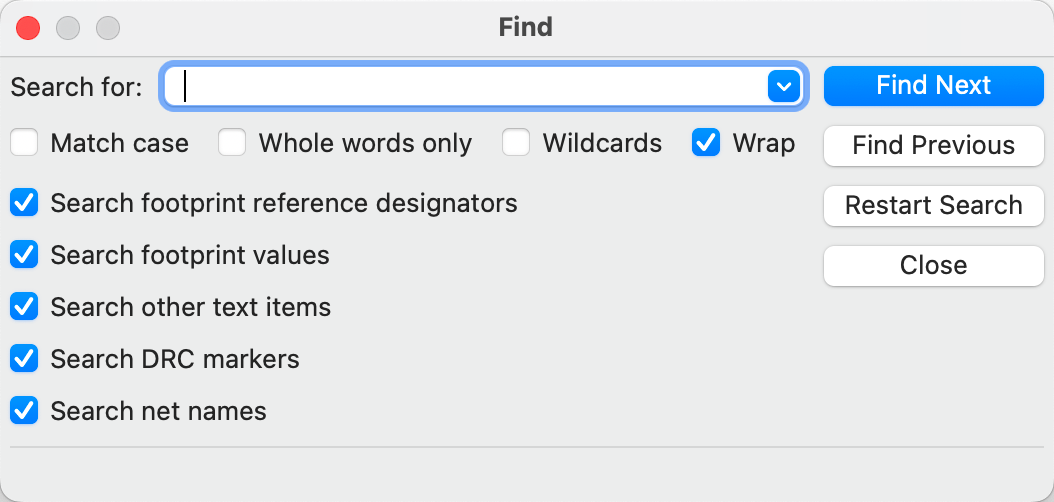

快捷键 Ctrl+F1 显示当前快捷键列表。默认的快捷键列表包含在本手册的 Actions Reference 部分。

本手册中描述的快捷键使用了标准 PC 键盘上的按键标签。在苹果键盘布局中,使用 Cmd 键来代替 Ctrl,使用 Option 键来代替 Alt。

许多操作默认没有分配快捷键,但可以使用快捷键编辑器(偏好设置 → 偏好设置… → 快捷键 )分配或重新定义快捷键。

| 通过快捷键可用的许多操作也可在上下文菜单中使用。要访问上下文菜单,请在编辑画布中单击鼠标右键。根据选择的内容或处于活动状态的工具,将提供不同的操作。 |

快捷键存储在 KiCad 的配置目录下的 user.hotkeys 文件中。这个位置是特定于平台的:

-

Windows:

%APPDATA%\kicad\9.0\user.hotkeys -

Linux:

~/.config/kicad/9.0/user.hotkeys -

macOS:

~/Library/Preferences/kicad/9.0/user.hotkeys

KiCad 可以使用快捷键编辑器中的 导入快捷键 按钮从 user.hotkeys 文件中导入快捷键设置。

显示和选择控件

板层

PCB 编辑器中的层代表电路板上的物理铜层,以及用于定义丝印、阻焊和电路板边框等的图形层。 在编辑器中,总有一个层是活动的。 活动图层绘制在其他图层之上,并将成为分配给新创建对象的图层。 活动层在顶部工具栏的图层选择器下拉框中显示,在外观面板中也被突出显示。 要改变活动层,你可以左键单击外观面板中的层名,使用顶部工具栏中的下拉层选择器,或使用快捷键。 图层可以被隐藏以简化电路板视图。 你可以隐藏一个层,即使它是活动层。

电路板层的显示顺序

The display order for board layers is dynamic and depends on which layer is selected as the active layer. The active layer is always drawn on top of other layers. In addition, layers that are related to the active layer are drawn on top of layers that are unrelated. For example, if you make B.Silkscreen the active layer, then all of the other back layers (B.Cu, B.Adhesive, B.Paste, B.Mask, B.Fab, and B.Courtyard) will be drawn on top of the front, user, and inner copper layers, with B.Silkscreen topmost. If you make Edge.Cuts active, then it will be drawn on top, and the User.* layers and Margin will also be be brought to the front.

| Selected objects are always drawn on top, even if they are not on the active layer. |

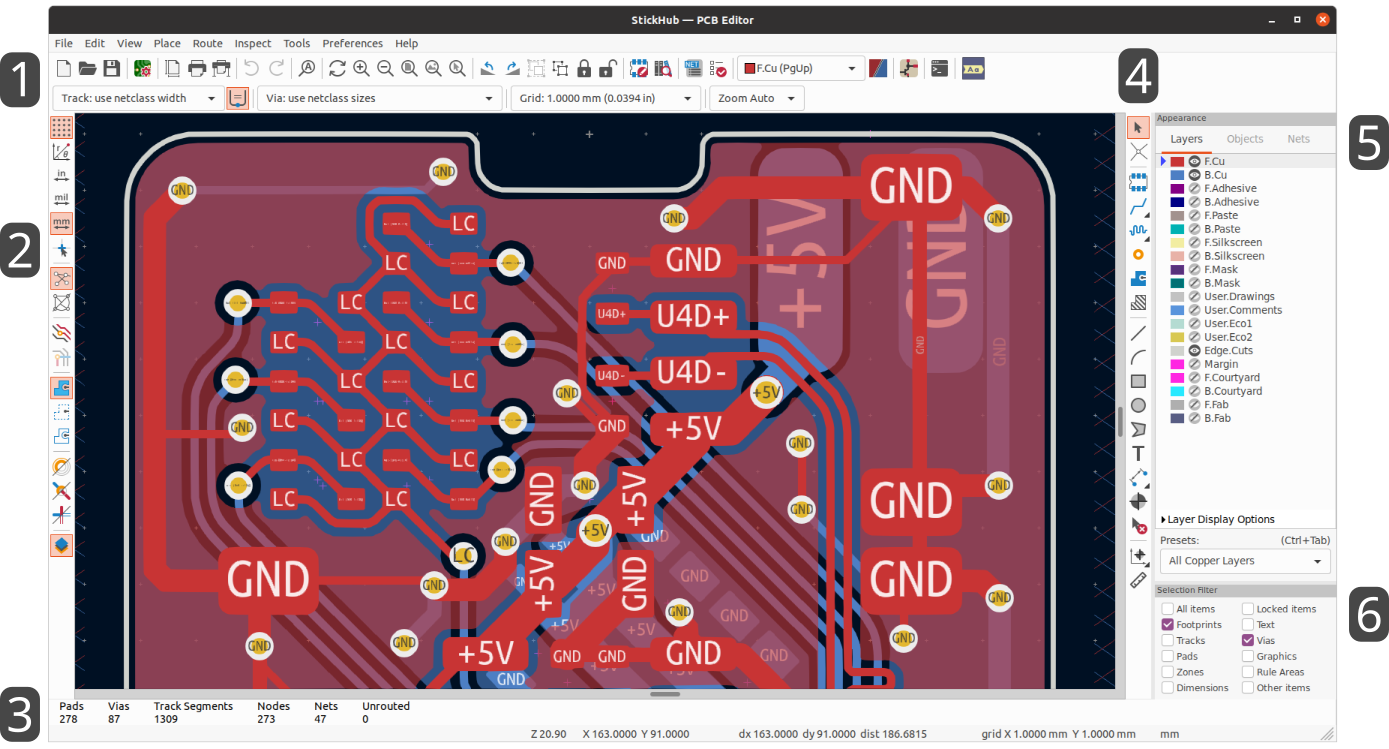

外观面板

外观面板提供了管理 PCB 编辑器绘图画布中的对象的可见性、颜色和不透明度的控制。 它有三个标签:层标签包含电路板层的控制,对象标签包含不同类型图形对象的控制,网络标签包含飞线和铜对象的外观控制。

图层控件

在外观面板的 “层” 选项卡中,每个电路板层都显示了其颜色和可见性状态。 活动层在色块的左边有一个箭头指示器。 左键点击一个图层来选择它作为活动图层。 左键单击相应的可见性图标,在可见和隐藏之间切换该图层。 双击或中击色块来改变该图层的颜色。

| 必须先在偏好选项中创建自定义颜色主题, 然后才能在“外观”面板中更改图层颜色。 |

在图层列表下方是一个包含图层显示选项的可展开面板。第一个设置控制非活动图层的显示方式:正常、暗显或隐藏。层显示模式可用于简化视图并聚焦于单个层。当非活动层显示模式为 "暗显" 或 "隐藏" 时,不能选择非活动层上的对象。您可以使用快捷键 Ctrl+H 快速切换这些显示模式。

Flip board view will show the board as if you are looking from the bottom (that is, mirrored around the Y-axis). This option is also available in the View menu.

| 翻转电路板视图不会更改可视层顺序,活动层将保持在最前面,其他层按正常顺序紧随其后。 |

对象控件

外观面板的 "对象" 选项卡与 "图层" 选项卡类似。 主要区别在于,有些对象没有颜色设置,而四种类型的对象(布线、过孔、焊盘和敷铜)有不透明度控制滑块。 这里的不透明度设置将与图层颜色中设置的任何不透明度相乘。 默认情况下,所有对象都是完全不透明的,除了敷铜,敷铜被设置为半透明,以便通过敷铜区域更容易看到对象。

图层预设

图层预设存储了哪些图层和对象是可见和隐藏的,以便于调用。 有几个内置的图层预设,您也可以保存您自己的自定义预设。 自定义预设存储在一个电路板的工程设置中,因为预设可能是特定于某个电路板的层叠。

要加载一个预设,请从外观面板底部的预设下拉菜单中选择它,或者通过按住 Ctrl 并按 Tab 来使用快速切换器。 一旦快速切换器窗口出现,你可以按 Tab 和 Shift+Tab 来循环浏览可用的预设。 当你放开 Ctrl 键时,高亮显示的预设将被加载。

To save a custom preset, first use the visibility controls to choose which layers you want visible, then choose Save preset… from the Presets drop-down menu. Give your preset a name and it will now be available via the drop-down menu and the quick switcher. To modify a custom preset, follow the same process and save the modified version with the same name to overwrite the existing version. To delete a custom preset, choose the Delete preset… option from the drop-down menu and select the preset to be deleted from the list.

Viewports

Viewports store the current view location and zoom level so you can quickly switch back to it later, or switch between several saved views.

To load a viewport, choose it from the Viewports drop-down menu at the bottom of the appearance panel or use the quick switcher by holding down Shift and pressing Tab. Once the quick switcher window appears, you can press Tab to cycle through the stored viewports. When you let go of the Shift key, the highlighted viewport will be loaded.

To save a new viewport, scroll and zoom to show the desired area of the board, then choose Save viewport… from the Viewports drop-down menu. Give your viewport a name and it will now be available via the drop-down menu and the quick switcher. To modify an existing viewport, save a new viewport with the same name to overwrite the existing version. To delete a viewport, choose the Delete viewport… option from the drop-down menu and select the preset to be deleted from the list.

网络和网络类控件

外观面板的网络选项卡显示电路板中所有网络和网络类的列表。每个网络都有一个可见性控件,用于控制该网络在飞线中的可见性。在飞线中隐藏网络不会改变电路板的连接性,也不会影响设计规则检查器;这只是为了使飞线更容易理解。

Each net and net class can also have a color assigned. By default, this color applies to the ratsnest lines for the net (or for all the nets in the net class). Nets have no color by default; this is indicated by a checkerboard pattern in the color swatch. Double-click or right-click a net or net class color swatch to set the color. To give a net class the same color it has in the schematic, right click the net class and select Use color from schematic.

| 默认网络类不能分配颜色, 因为该类中的网络将仅使用颜色主题定义的默认飞线颜色。 |

您还可以通过外观面板选择并高亮网络和网络类:右击网络或网络类以在菜单中显示这些选项。

网络类列表下面是一个包含网络显示选项的可扩展面板。第一个选项控制如何应用网络颜色。当选择了 “所有” 时,属于网络或网络类的所有铜对象 (焊盘、布线、过孔和敷铜) 都将呈现所选的颜色。当选中 “飞线” (默认值)时,只有飞线受网络和网络类颜色的影响。 当选择 “无” 时,网络和网络类颜色被忽略。

第二个选项控制如何绘制飞线。“所有图层” 表示将在所有未连接的项目之间绘制飞线。“可见层” 意味着不会向隐藏层上的项目绘制任何最新的飞线,即使这些项目是未连接的。

| You can configure the thickness of ratsnest lines in the PCB Editor Editing Options section of the Preferences dialog, to make the ratsnest more or less visible. |

选择和选择筛选器

选择编辑画布中的对象是用鼠标左键完成的。 单独点击一个对象将选择该对象,而拖动将执行框选。 从左到右的框选将只选择完全在框内的对象。 从右到左的方框选择将选择任何接触到方框的对象。从左到右的选择框是用黄色画的,光标表示排他性选择,从右到左的选择框是用蓝色画的,光标表示包容性选择。

可以通过在单击或拖动的同时按住快捷键来修改选择操作。单击以选择单个对象时,将应用以下快捷键:

| 修改键 (Windows) | 修改键 (Linux) | 修改键 (macOS) | 选择效果 |

|---|---|---|---|

Ctrl |

Ctrl |

Cmd |

切换选择。注意:Ctrl+点击可以被重新设置为高亮网络。 偏好设置 → PCB 编辑器 → 编辑选项. |

Shift |

Shift |

Shift |

将该对象添加到现有的选择中。 |

Ctrl+Shift |

Ctrl+Shift |

Cmd+Shift |

从现有的选择中删除对象。 |

长点击 |

长点击或 Alt |

长点击或 Option |

从弹出式菜单中澄清选择。 |

拖动以执行选框时,将应用以下快捷键:

| 修改键 (Windows) | 修改键 (Linux) | 修改键 (macOS) | 选择效果 |

|---|---|---|---|

Ctrl |

Ctrl |

Cmd |

切换选择。 |

Shift |

Shift |

Shift - Shift |

将对象添加到现有的选择中。 |

Ctrl+Shift |

Ctrl+Shift |

Cmd+Shift |

从现有选择中删除对象。 |

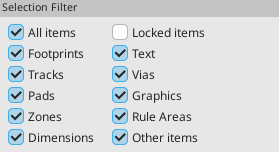

PCB 编辑器窗口右下角的选择过滤器面板控制哪些类型的对象可以用鼠标选择。 关闭不需要的对象类型的选择,可以使在密集的电路板上选择项目更加容易。 "所有项目" 复选框是打开和关闭其他项目的一个快捷方式。 "锁定的项目" 复选框与其他项目无关,它控制是否可以选择被锁定的项目。 你可以右键单击选择过滤器中的任何对象类型,快速改变过滤器,只允许选择该类型的对象。

当一个连接的铜对象被选中时,你可以使用右键菜单中的 "扩展选择" 命令或快捷键 U 将选择扩展到同一网络的其他铜线对象。 第一次运行这个命令时,选择将被扩展到最近的焊盘。 第二次,选择将被扩展到所有层上的所有连接项。

选择一个对象会在窗口底部的信息面板上显示该对象的信息。双击一个对象可以打开一个窗口来编辑该对象的属性。

按 Esc 将始终取消当前工具或操作,并返回到选择工具。在选择工具处于活动状态时按 Esc 将清除当前选择。

网络高亮

电气网络(或一组网络)可以在 PCB 编辑器中被高亮显示,以显示该网络是如何在 PCB 上布线的。 通过在 PCB 编辑器中选择要高亮的网络,或者在启用交叉探测高亮时在原理图编辑器中选择相应的网络,可以激活网络的高亮(见下文)。 当网络高亮激活时,高亮的网络将以较亮的颜色显示,所有其他对象将以比正常颜色更暗的颜色显示。

There are several ways to select a net or nets to highlight in the PCB editor:

-

Use the hotkey ` after selecting a copper object, or while hovering over a copper object

-

Right click a copper object in the editing canvas and select Net Inspection Tools → Highlight Net

-

Right click a net in the Nets tab of the Appearance panel and select Highlight

-

Double click a net in the Net Inspector

When you press the Highlight Net hotkey, the nets of any selected copper items will be highlighted. If no copper items are selected, the net of the copper item under the editor cursor will be highlighted.

Net highlighting can be cleared by using the Clear Net Highlight action (hotkey ~) or by using the Highlight net tool on an empty region in the board. By default, Esc also clears net highlighting, but this can be disabled if desired in Preferences → PCB Editor → Editing Options.

选择一个或多个网络进行高亮时,左侧工具栏上的切换网络高亮显示操作将被激活(也可通过快捷键 Ctrl+` 访问)。此操作将打开或关闭高亮,而无需选择要高亮的新网络。

从原理图交叉探测

KiCad 允许在原理图和 PCB 之间进行双向交叉探测。 有几种不同类型的交叉探测。

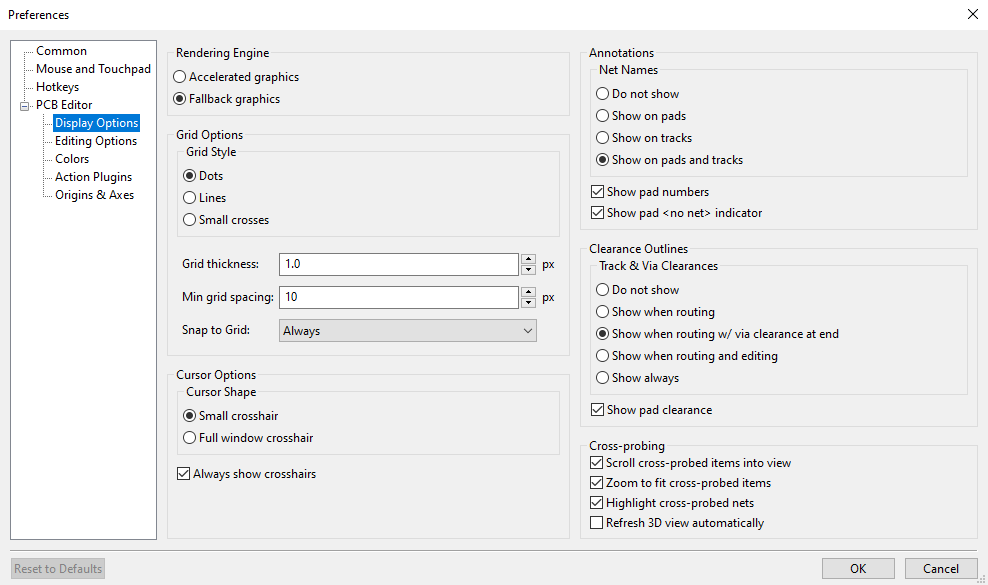

Selection cross-probing allows you to select a symbol or pin in the schematic to select the corresponding footprint or pad in the PCB (if one exists) and vice-versa. By default, cross-probing will result in the display centering on the cross-probed item and zooming to fit. You can disable the centering and zooming behavior, or disable selection cross-probing entirely, in the Display Options section of the Preferences dialog. Even when selection cross-probing is disabled, you can manually cross-probe from the schematic to the PCB by right-clicking an object and selecting Select on PCB, or from the PCB to the schematic by right-clicking an object and choosing Select → Select on Schematic.

Highlight cross-probing allows you to highlight a net in the schematic and PCB at the same time. If the option "Highlight cross-probed nets" is enabled in the Display Options section of the Preferences dialog, highlighting a net or bus in the schematic editor will cause the corresponding net or nets to be highlighted in the PCB editor.

左侧工具栏显示控件

左侧的工具栏提供了改变 PCB 编辑器中对象显示的选项。

|

Turns grid display on/off. Note: by default, hiding the grid does not disable grid snapping. This behavior can be changed in the Display Options section of Preferences. |

|

Turns item-specific grid overrides on/off. |

|

Switch between polar and Cartesian coordinate display in the status bar. |

|

Display/entry of coordinates and dimensions in inches, mils, or millimeters. |

|

Switches between full-screen and small editing cursor (crosshairs). |

|

Switches between free angle and 45 degree mode for placement of new tracks, zones, graphical shapes, dimensions, and other objects. You can also toggle between free angle and 45 degree mode using Shift+Space. |

|

Turns the ratsnest display on/off. |

|

Switches between straight and curved ratsnest lines. |

|

Switches the non-active layer display mode between Normal and Dim. Note: this button will be highlighted when the non-active layer display mode is either Dim or Hide. In both cases, pressing the button will change the layer display mode to Normal. The Hide mode can only be accessed via the controls in the Appearance Panel or via the hotkey Ctrl+H. |

|

When a net has been selected for highlighting, switches the highlighting on or off. Note: this button will be disabled when no net has been highlighted. To highlight a net, use the hotkey `, right-click any copper object in the net and choose Highlight Net from the Net Tools menu, or right-click the net in the list in the Nets tab of the Appearance panel. |

|

Show zone filled areas. |

|

Show zone outlines only. |

|

Switches display of pads between filled and outline mode. |

|

Switches display of vias between filled and outline mode. |

|

Switches display of tracks between filled and outline mode. |

|

Shows or hides the Appearance and Selection Filter panels on the right side of the editor. |

|

Shows or hides the Properties Manager panel on the left side of the editor. |

创建 PCB

PCB 的基本概念

KiCad 中的印刷电路板通常由代表电子元件及其焊盘的 封装、定义这些焊盘如何彼此连接的 网络、形成每个网络中焊盘之间的铜连接的 布线、过孔 和 敷铜 以及定义电路板边缘、丝印标记和任何其他所需信息的各种图形形状组成。

KiCad 通常会将 PCB 上的网络信息与相关的原理图保持同步,但也可以直接在 PCB 编辑器中创建和编辑网络。

性能

KiCad 能够创建多达 32 个铜层、14 个技术层 (丝印、阻焊、元件粘合剂、锡膏等) 和 13 个通用绘图层的印刷电路板。

KiCad 中所有对象的内部测量分辨率为 1 纳米,测量值以 32 位整数存储。 这意味着可以创建最大约 4 米乘 4 米的电路板。

KiCad 目前支持每个工程/原理图一个电路板文件。

从原理图开始

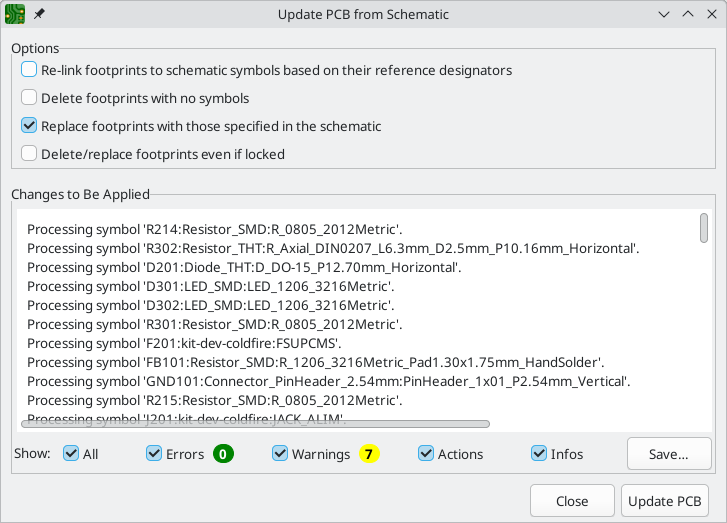

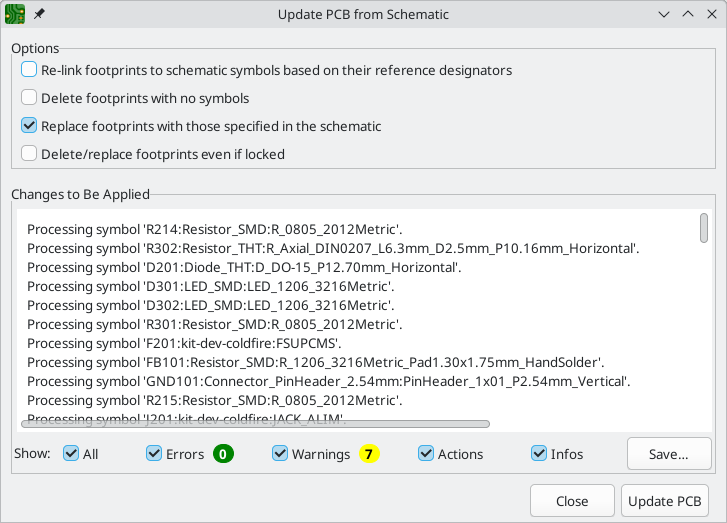

Creating a board from a schematic is the recommended workflow for KiCad. When you create a new project, KiCad will generate an empty board file with the same name as the project. To start designing the board after you have created a schematic, simply open the board file. You can do this either from the KiCad project manager, or by clicking the "Open PCB in board editor" button in the schematic editor. To import the schematic design information into the board editor, including footprints and net connections, use the Tools → Update PCB from Schematic… action (F8). You can also use the ![]() icon in the top toolbar.

icon in the top toolbar.

| 从原理图更新 PCB 是将设计信息从原理图转移到 PCB 的首选方法。在旧版本的 KiCad 中,相应的过程是将网表从原理图编辑器中导出并导入到电路板编辑器中。现在已经没有必要使用网表文件了。 |

关于从原理图更新PCB工具的更多信息,请参见手册的 [正向批注,正向批注] 部分。

从头开始

也可以创建一个没有匹配原理图的电路板,不过这种工作流程有一些限制,不建议大多数用户使用。为此,您必须独立启动 PCB 编辑器(而不是从 KiCad 工程管理器启动)。在开始设计之前,最好先保存电路板文件,这也将创建一个项目文件来存储电路板设置。 使用文件菜单中的 "另存为… " 来选择保存电路板文件的位置。一个具有相同名称的项目文件将被创建在你选择保存电路板文件的相同位置。

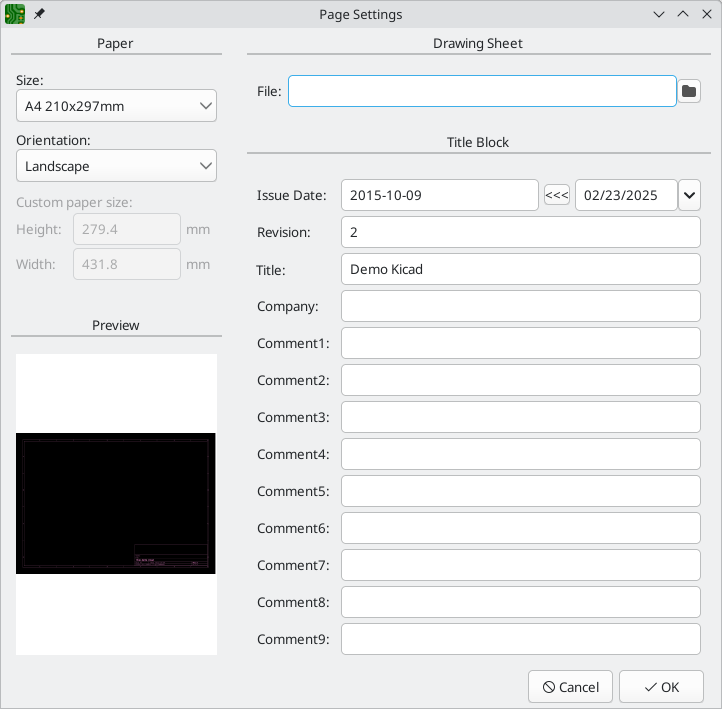

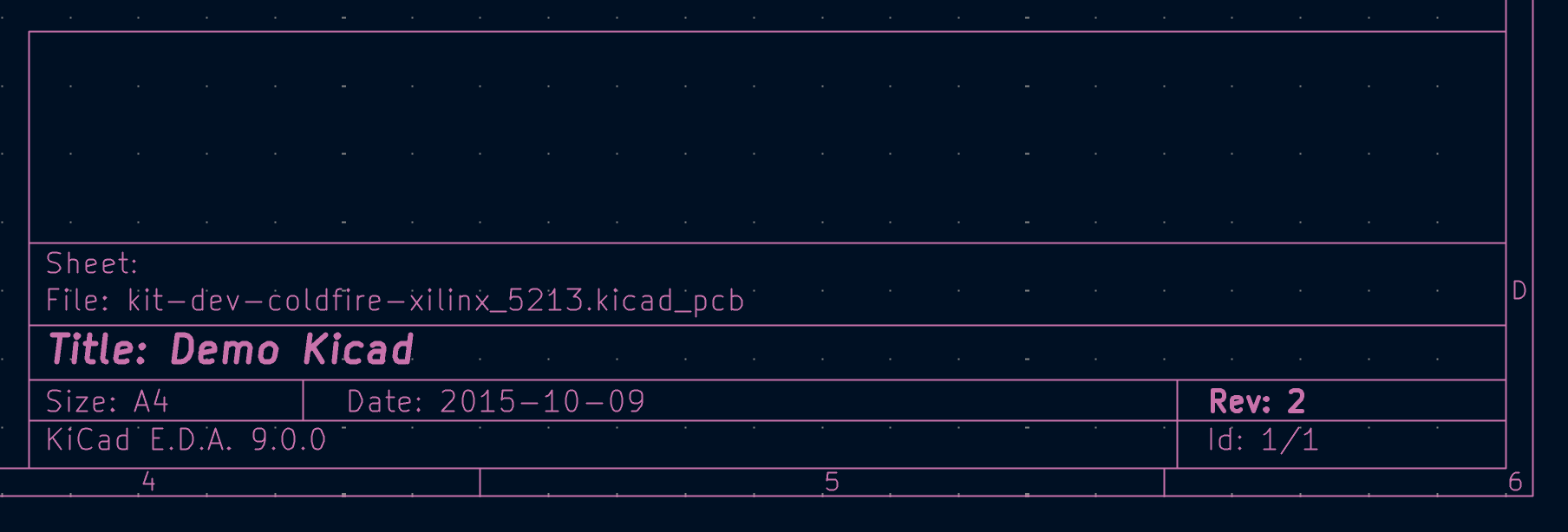

电路板设置

在开始设计电路板之前,使用电路板设置对话框来配置电路板的基本参数。要打开电路板设置,请单击顶部工具栏中的 ![]() 图标或从文件菜单中选择 "电路板设置…"。

图标或从文件菜单中选择 "电路板设置…"。

配置电路板层叠和物理参数

在 "电路板设置" 中,有两个部分用于配置电路板的层叠和层。 "电路板编辑器层" 部分用于启用或禁用技术层(非铜层),如果需要的话,还可以给各层自定义名称。 物理层叠部分用于配置铜层的数量,以及铜层和电介质层的物理参数,如厚度和材料类型。介电层、阻焊层和丝印层可以被分配颜色,这将影响电路板在 3D 查看器中的外观。

要配置电路板的层叠,从物理层叠部分开始:

Set the number of copper layers in the upper left corner and then enter the physical parameters of the stackup if desired. These parameters may be left at their default values, but note that the board thickness value will be used when exporting a 3D model of the board, and layer thicknesses will be included in net length calculations for any nets that include vias. If you plan to use these features, it is a good idea to ensure that the stackup thickness is correct.

| KiCad 目前仅支持铜层数为偶数的层叠。 要创建具有奇数层的设计 (例如,柔性印刷电路板或金属芯印刷电路板), 只需选择下一个最高的偶数,而忽略多余的层。 |

Next, if desired, use the Board Editor Layers section to rename layers or hide non-copper layers that you will not be using in the design. For example, if you will not use a back silkscreen on the design, uncheck the box next to the B.Silkscreen layer. Some layers, like F.Cu / B.Cu or Edge.Cuts, are required layers and therefore cannot be disabled.

| 在电路板编辑器层部分,可以将铜层指定为信号层、电源层、混合层或跳线层。 本指南仅供用户参考。 无论在此对话框中将类型配置为什么,都可以在任何铜层上布线和敷铜。 |

You can add additional user-defined layers (User.1, User.2, etc.) by clicking the Add User Defined Layer… button in the top right. User-defined layers can’t be used for routing, but they can contain arbitrary graphics or other information. By default, user layers are auxiliary layers, meaning that whatever information they contain does not correspond to either the front or back of the board. User layers can instead be set to Off-board, front or Off-board, back, in which case they correspond to the selected side of the board. Items on such layers can be flipped from front to back in the same way as objects on physical front/back layers. Adjacent front/back layers are treated as paired: if User.2 is defined as a front layer and User.3 is defined as a back layer, flipping an object on User.2 will move it to User.3, and vice versa.

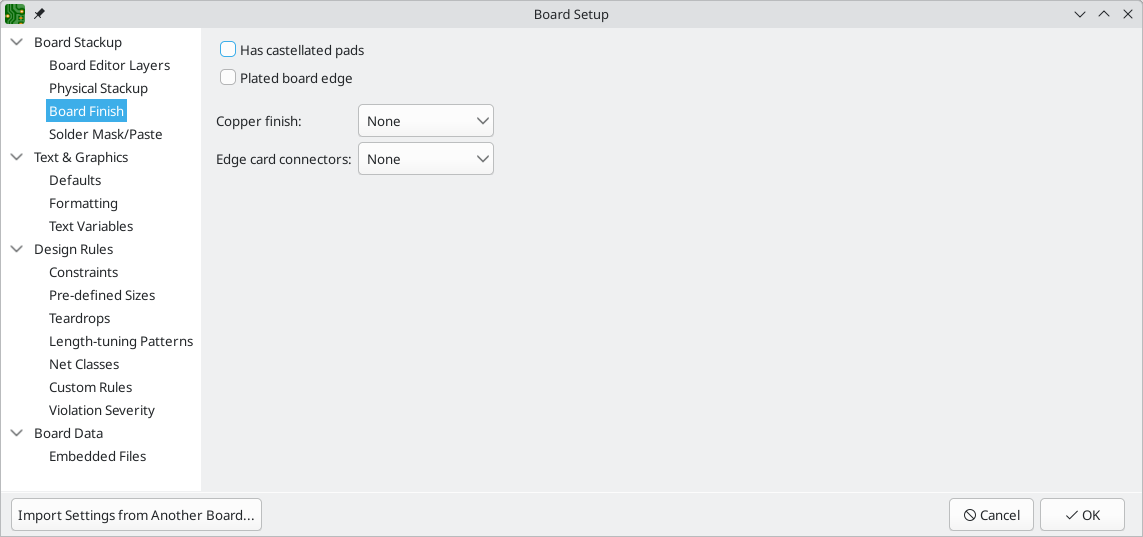

在电路板编辑器对话框的电路板表面处理(Board Finish)和阻焊/锡膏部分可以找到一些其他的电路板层叠设置。电路板表面处理部分包含用于定义铜的表面处理和特殊功能 (如刻痕或边缘电镀) 的设置。请注意,这些设置目前只影响作为 Gerber 文件一部分的电路板属性输出。

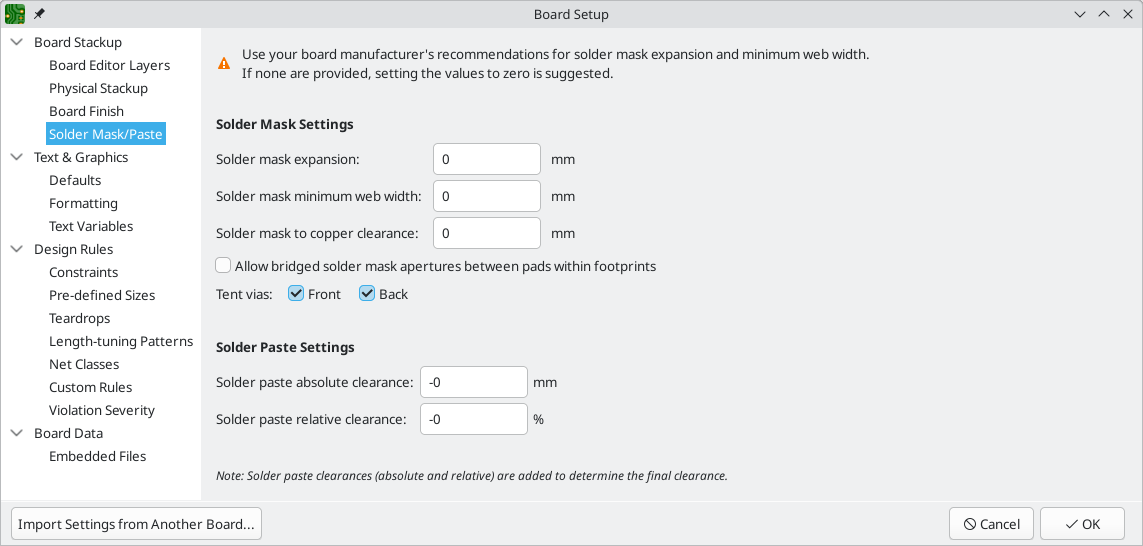

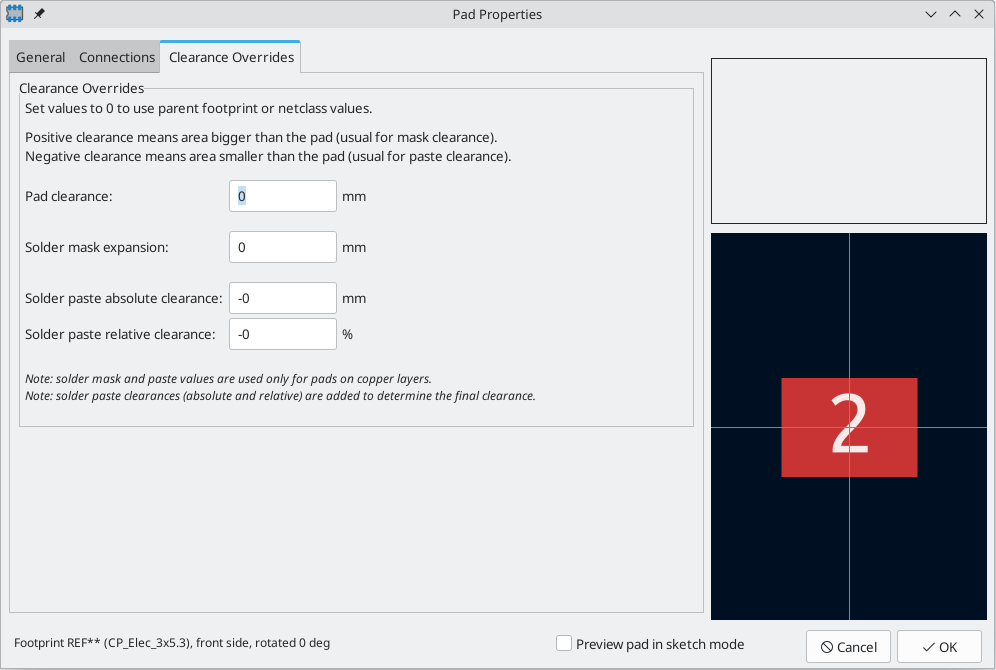

阻焊/锡膏部分允许全局调整电路板上焊盘的铜形和阻焊/锡膏形之间的间隙(正或负)。 这些值将被添加到在个别封装或焊盘上设置的任何间隙覆盖。 正的间隙值将导致阻焊层或锡膏开口的形状比铜的形状 更大。 负的间隙值将导致开口比铜的形状 更小。

| 大多数商业 PCB 制造商希望这些值为零,并在 CAM 过程中自行调整阻焊和锡膏开口。 通常最好将这些值保留为默认值零, 除非您自己制作 PCB, 或者您的制造商有具体建议使用不同的值。 |

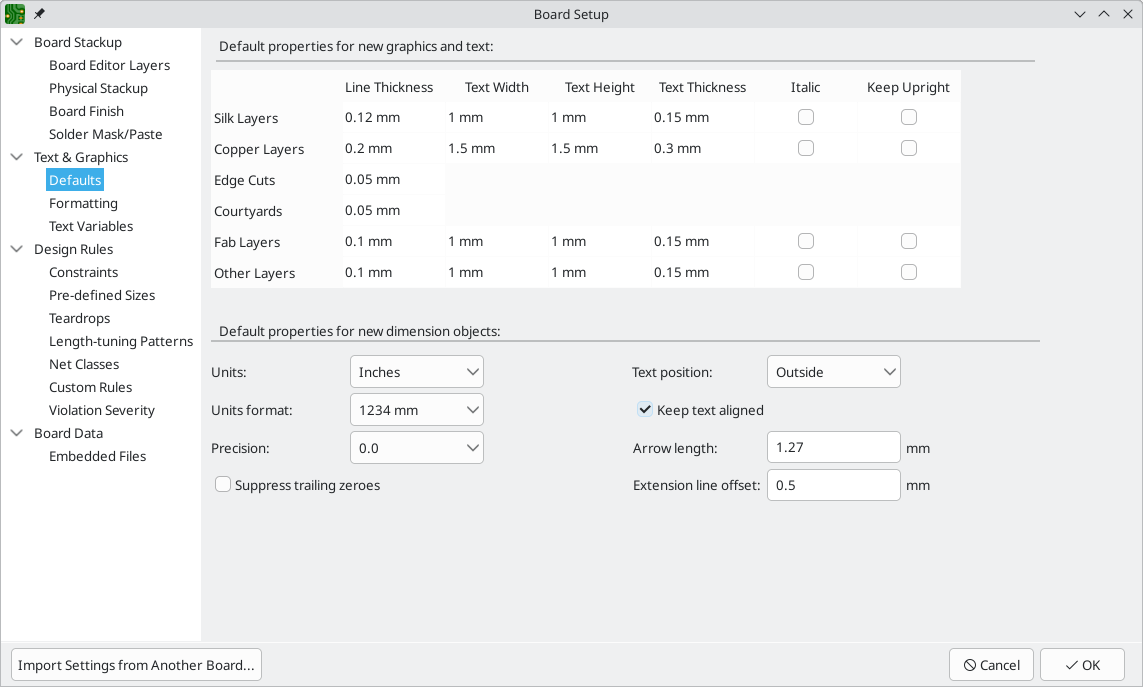

配置默认文本和图形设置

电路板设置对话框的文本和图形默认值部分可用于配置将用于放置在电路板上的新文本和图形形状的属性。

可以为对话框中显示的六种不同类别的图层配置线粗细、文本大小和文本外观。此外,可以为所有图层配置标注对象的特性。有关标注属性的更多详细信息,请参阅下面的标注部分。

虚线的外观是在 "格式化" 部分控制的。虚线长度 控制虚线的长度,而 间隔长度 控制虚线和圆点之间的间距。虚线和间隔的长度是相对于行宽而言的:间隔长度为 2 意味着是行宽的两倍。

文本替换变量可以在文本变量部分创建。 这些变量允许你将变量名称替换为任何文本字符串。 这种替换发生在变量名称在 ${VARIABLENAME} 的变量替换语法内的任何地方。

例如,您可以创建一个名为 VERSION 的变量,并将文本替换设置为 1.0。 现在,在 PCB 上的任何文本对象中,你可以输入 ${VERSION},KiCad 将替代 1.0。 如果你把变量改为 2.0,每个包括 ${VERSION} 的文本对象都会自动更新。 你也可以混合使用普通文本和变量。 例如,你可以创建一个文本对象,内容为 版本:${VERSION},它将被替换为 版本:1.0。

文本变量也可以在 原理图设置 中创建。 文本变量是项目范围内的;在原理图编辑器中创建的变量在电路板编辑器中也可用,反之亦然。

还有一些 内置系统文本变量。

配置设计规则

Design rules control the behavior of the interactive router, the filling of copper zones, and the design rule checker. Design rules can be modified at any time, but we recommend that you establish all known design rules at the beginning of the board design process.

约束

Basic design rules are configured in the Constraints section of the Board Setup dialog. Constraints in this section apply to the entire board and should be set to the values recommended by your board manufacturer. Any minimum value set here is an absolute minimum and cannot be overridden with a more specific design rule. For example, if you need the copper clearance on part of a board to be 0.2mm and in the rest 0.3mm, you must enter 0.2mm for the minimum copper clearance in the Constraints section and use a net class or custom rule to set the larger 0.3mm clearance.

除了设置最小间隙外,还可以在此处配置许多功能:

| Setting | Description |

|---|---|

Arc/circle approximated by segments |

In some situations, KiCad must use a series of straight line segments to approximate round shapes such as those of arcs and circles. This setting controls the maximum error allowed by this approximation: in other words, the maximum distance between a point on one of these line segments and the true shape of the arc or circle. Setting this to a lower number than the default value of 0.005mm will result in smoother shapes, but can be very slow on larger boards. The default value typically results in arc approximation error that is not detectable in the manufactured board due to manufacturing tolerances. |

Allow fillets outside zone outline |

Zones can have fillets (rounded corners) added in the Zone Properties dialog. By default, no zone copper, including fillets, is allowed outside the zone outline. This effectively means that inside corners of the zone outline will not be filleted even when a fillet is configured. By enabling this setting, inside corners of the zone outline will be filleted even though this results in copper from the zone extending outside the zone outline. |

Minimum thermal relief spoke count |

This sets the minimum acceptable number of thermal relief spokes connecting a pad to a zone. A DRC violation will be generated if this constraint is violated. |

Include stackup height in track length calculations |

By default, the length tuner uses the height of the stackup to calculate the additional length of a track that travels through vias from one layer to another. This calculation relies on the board stackup height being correctly configured. In some situations, it is preferable to ignore the height of vias and just calculate the track length assuming that vias add no length. Disabling this setting will exclude via length from length tuner track length calculations. |

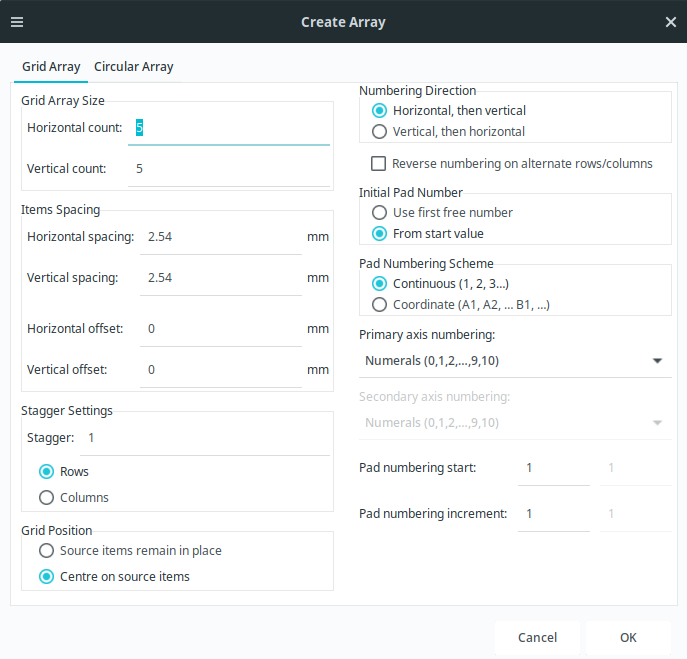

预定义大小

The pre-defined sizes section allows you to define the track and via dimensions you want to have available while routing tracks. Net classes can be used to define the default dimensions for tracks and vias in different nets (see below) but defining a list of sizes in this section will allow you to step through these sizes while routing. For example, you may want the default track width on a board to be 0.2 mm, but use 0.3 mm for some sections that carry more current, and 0.15 mm for some sections where space is limited. You can define each of these track widths in the Board Setup dialog and then switch between them when routing tracks.

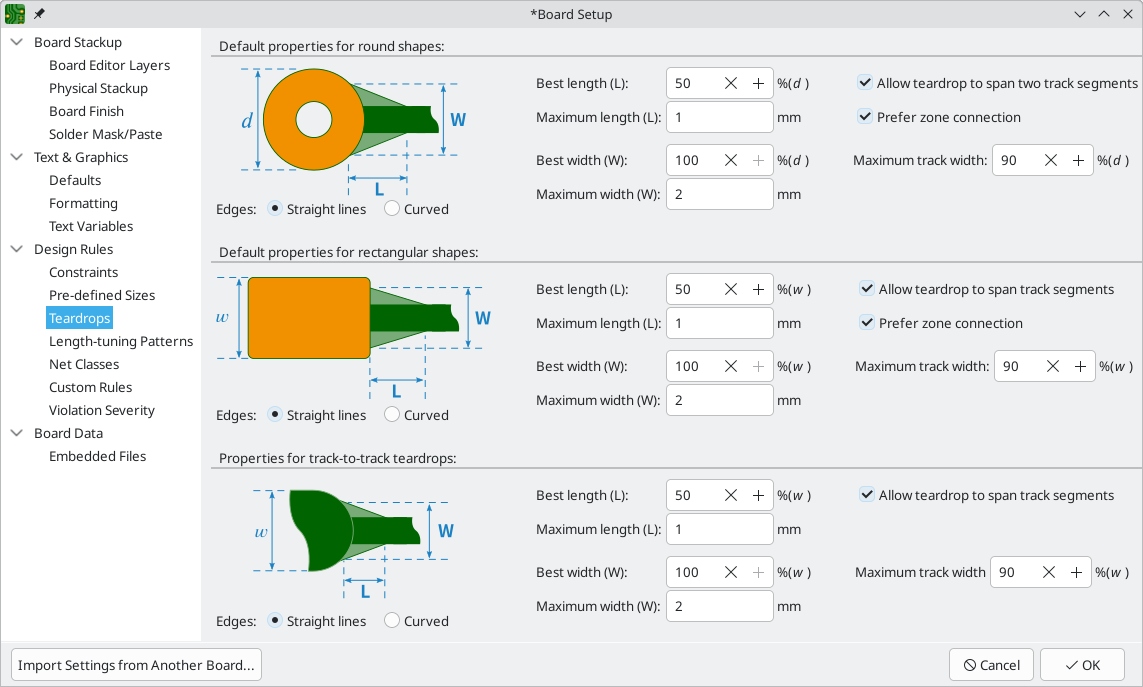

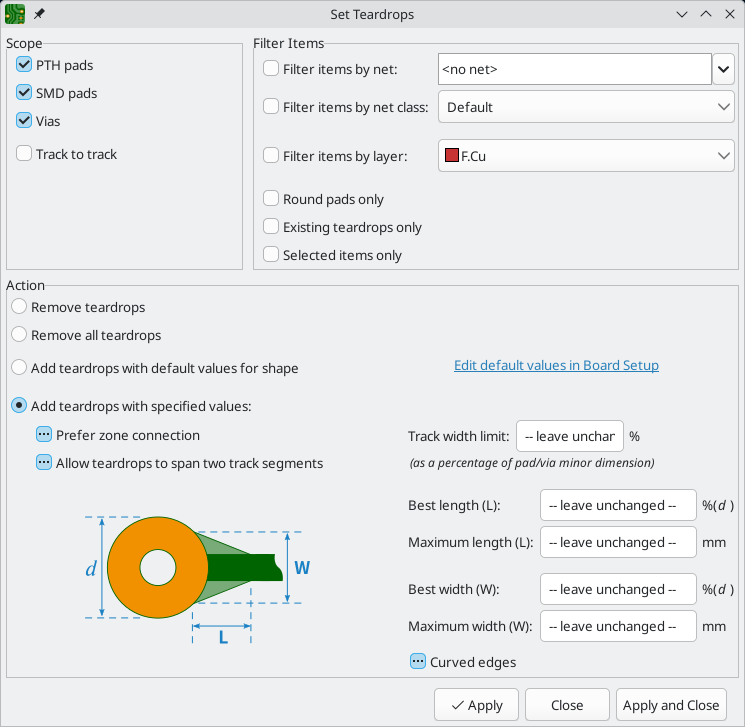

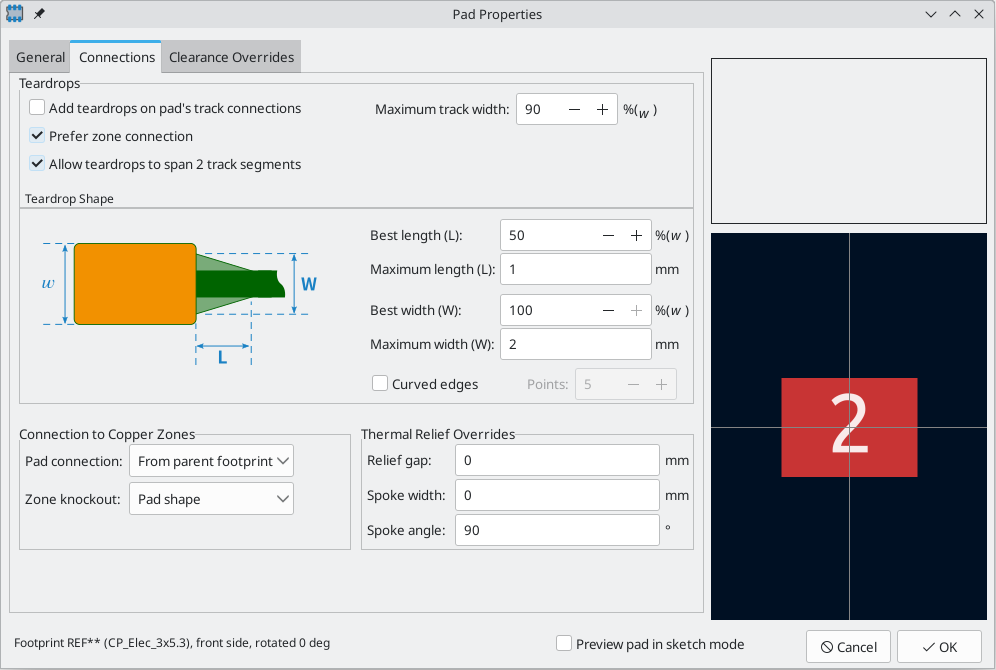

Teardrops

The teardrops section lets you set default parameters for various types of teardrops. There are different settings for teardrop connections to round objects, rectangular objects, and teardrop connections between tracks. The default teardrop parameters can be overridden when teardrops are added, and also changed in the properties for individual connected items. See the teardrops documentation for more information about each setting.

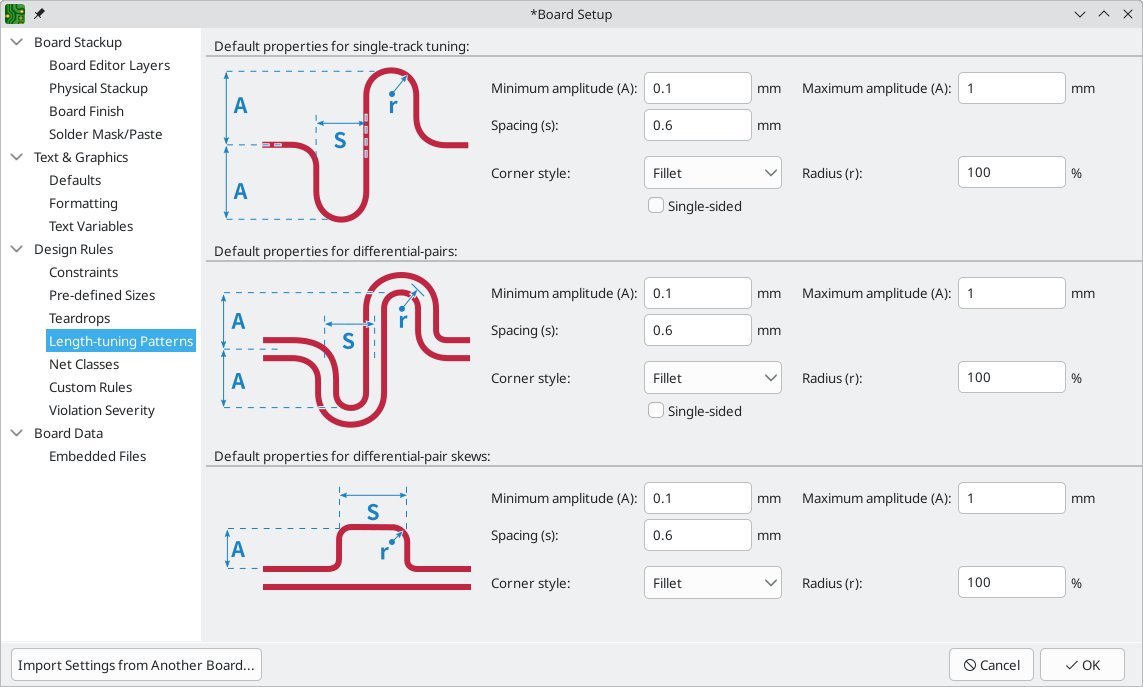

Length-tuning patterns

The length-tuning patterns section lets you set default parameters for each type of length-tuning pattern (single-track length, differential-pair length, and differential-pair skew). These defaults can be overridden in the properties of each tuning pattern added to the board. See the length tuning documentation for more information.

网络类

The Net Classes section allows you to configure routing and clearance rules for different classes of nets.

More than one net class can be assigned to a net. For nets with multiple net classes assigned, an effective aggregate net class is formed, taking any net class properties from the highest priority net class which has that property set. Net class priority is determined by the ordering in the Schematic or Board Setup dialogs. The Default net class is used as a fallback for any missing properties after all explicit net classes have been considered; this means that nets may be part of the Default net class even if they have other net classes explicitly assigned.

Net classes may be created and edited in either the Schematic or Board Setup dialogs.

网络类部分的上部有一个表格,显示了设计中的网络类和适用于每个网络类的设计规则。 每个类别都有铜的间隙、布线宽度、过孔尺寸和差分对尺寸的值。 这些值将在创建布线和过孔时使用,除非有更具体的规则覆盖它们(见下面的自定义规则)。

任何规则都不能覆盖电路板设置的约束条件部分中设置的最小值。

例如,如果您将网络类间距设置为 0.1 mm,但约束条件部分中的最小间距设置为 0.2 mm,

则该类网络的间距将为 0.2 mm。

|

The track widths and via sizes defined for each net class are used when the track width and via size controls are set to "use netclass values" in the PCB editor. These widths and sizes are considered the default, or optimal, sizes for that net class. They are not minimum or maximum values. Manually changing the track width or via size to a different value from that defined in the Net Classes section will not result in a DRC violation. To restrict track width or via size to specific values, use Custom Rules.

Each net class can also have a color assigned to it. Depending on how net colors are configured in the appearance panel, net class colors can override the default color for ratsnest lines or copper objects. In addition to arbitrary colors for each net class, you can set all net classes to use the same color as configured for them in the schematic editor by clicking the Import colors from schematic button. To use a layer’s default color instead of overriding it with a custom net class color, set the net class color to transparent.

The lower portion of the Net Classes section lists pattern-based net class assignments. Working with pattern-based net class assignments is explained in the Schematic Editor documentation; pattern-based assignments can be edited in either the Board or Schematic Setup windows.

Note that pattern-based assignments can be created directly from the PCB editing canvas by right clicking a copper track or zone and clicking Assign netclass…. Net classes can also be assigned in the schematic using net class directives or labels instead of pattern-based assignments.

自定义规则

自定义规则部分包含一个文本编辑器,用于使用自定义规则语言创建设计规则。 自定义规则用于创建基本约束或网络类设置没有涵盖的特定设计规则检查。

只有在自定义规则定义中没有错误时,才会应用自定义规则。 在关闭电路板设置之前,使用检查规则语法器按钮来测试定义并修复任何问题。

See Custom Design Rules in the Advanced Topics chapter for more information on the custom rules language as well as example rules.

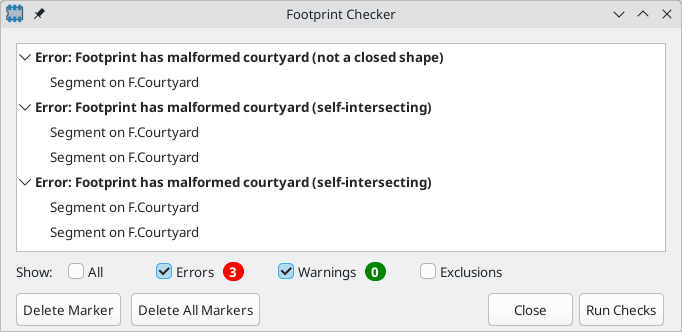

违规严重程度

违规严重性部分允许你配置每种设计规则检查的严重性。 每条规则可以被设置为创建一个错误标记、一个警告标记或没有标记(忽略)。

| 在设计规则检查器中可能会忽略个别规则违规。 在违规程度部分中将规则设置为忽略将完全禁用相应的设计规则检查。 请谨慎使用此设置。 |

For descriptions of each violation type, and how to ignore individual violations without disabling all violations of that type, see the DRC documentation.

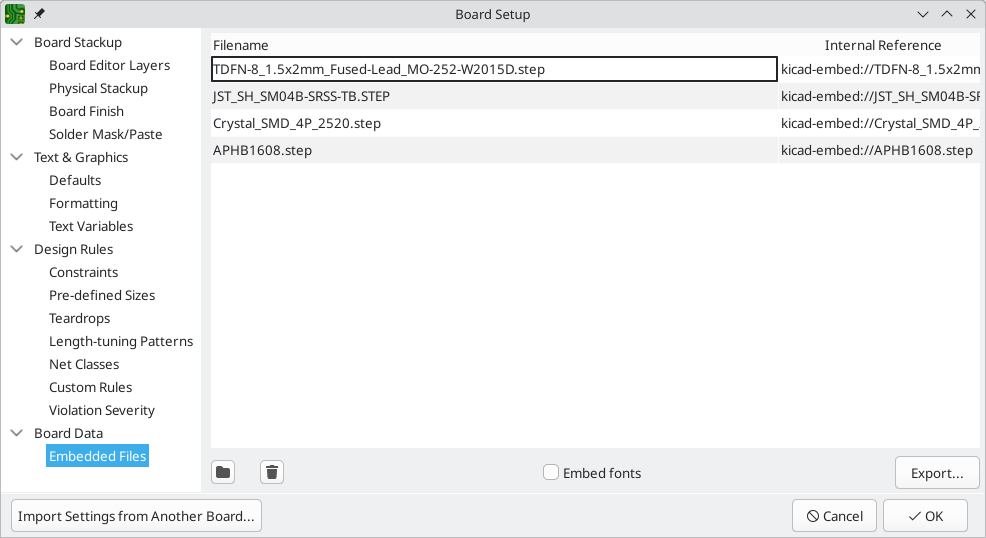

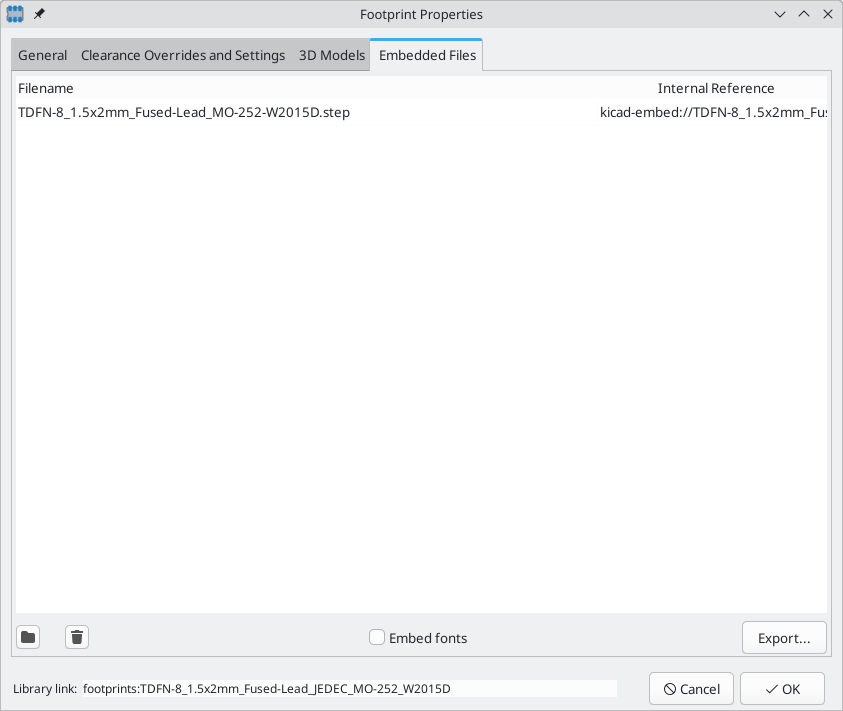

Embedding files

External files can be embedded within a board file. Embedding a file stores a copy of the file inside the board file. The design can then refer to the embedded copy of the file instead of the external file, which makes the project more portable as it doesn’t rely on an external file. Fonts, datasheets, drawing sheets, SPICE models, and footprint 3D models can be embedded and used within KiCad. Other arbitrary files can also be embedded to store them in the project for later export, but they are not used by any KiCad functionality. Files embedded in a board necessarily increase the board’s file size, although files are compressed before being embedded to minimize the space required.

Embedded files are managed in the Embedded Files section of Board Setup. All files embedded in a board are shown here. To embed a file inside a board, click the ![]() button and select the file. The file is then embedded inside the PCB and is listed in the embedded files list along with its embedded reference. The embedded reference is a unique identifier for the embedded file that begins with

button and select the file. The file is then embedded inside the PCB and is listed in the embedded files list along with its embedded reference. The embedded reference is a unique identifier for the embedded file that begins with kicad-embed://. You can use the embedded reference elsewhere in the Board Editor to refer to the embedded file as if it were an external file path. You can copy the embedded reference by right clicking and selecting Copy Embedded Reference. To remove an embedded file, click the ![]() button. Any remaining links to the removed file will become invalid.

button. Any remaining links to the removed file will become invalid.

| 3D models and drawing sheets can be embedded directly using the file browser when you add them to a footprint (3D models) or to a board (drawing sheets) by enabling the Embed Files option in the file browser. This is a single-step shortcut for adding the files in Board Setup and then referring to them by their embedded reference; the result is the same. |

To embed any fonts used in a board, check the Embed fonts checkbox. All fonts used in the board design will be embedded, so text using that font can be edited on any computer regardless of whether the font file is installed.

You can also embed files in a footprint, either in the board copy of a footprint or in a library. Such files will be available within the footprint instance but not within the larger board design or within other footprints. Files embedded in a footprint are deduplicated when the footprint is added to a board: if a file is embedded in a footprint, and multiple instances of that footprint are added to the board, only one copy of the file will be embedded, and all of the footprint instances will refer to the same embedded file.

As an example, to embed a 3D model in a project and use it within several footprints, you could embed the model using the Board Setup dialog, copy the internal reference, and paste the internal reference as a 3D model path in each footprint that uses that model. Alternatively, you could embed the model within a single footprint, either in the board or in the source footprint library. In this case, the footprint itself is portable if you export the footprints from the board, and the model embedding is managed in the footprint’s properties rather than Board Setup. A more convenient way to achieve the same thing, however, is to open the footprint’s properties dialog, add a 3D model file, and enable the Embed File option in the file browser. Again, this could be done for a footprint in the board or for a footprint in the source footprint library.

Files can also be embedded in schematics.

导入设置

您可以从现有电路板导入部分或全部电路板设置。 这种技术可以用来创建一个 "模板" 电路板板,其中有你想在多个设计中使用的设置,然后将这些设置从模板板中导入到每个新板中,而不是手动输入。

To import settings, click the Import Settings from Another Board… button at the bottom of the Board Setup dialog and then choose the kicad_pcb file you want to import from. Select which settings you want to import and the current settings will be overwritten with the values from the chosen board.

The settings that are available to import are:

-

Board layers and physical stackup

-

Solder mask/paste defaults

-

Text and graphics default properties

-

Text & graphics formatting

-

Design rule constraints

-

Predefined track & via dimensions

-

Teardrop defaults

-

Length-tuning pattern defaults

-

Net classes

-

Custom rules

-

Violation severities

编辑电路板

放置和绘制操作

放置和绘图工具位于右侧工具栏中。 当一个工具被激活时,它将一直处于激活状态,直到选择了一个不同的工具或用 Esc 键取消该工具。 当任何其他工具被取消时,选择工具总是被激活。

某些工具栏按钮在调色板中有多个可用工具。这些工具由按钮右下角的小箭头表示:

要显示调色板,你可以在工具上点击并按住鼠标按钮,或者点击并拖动鼠标。 调色板关闭时将显示最近使用的工具。

|

Selection tool (the default tool). |

|

Local ratsnest tool: when the board ratsnest is hidden, selecting footprints with this tool will show the ratsnest for the selected footprint only. Selecting the same footprint again will hide its ratsnest. The local ratsnest setting for each footprint will remain in effect even after the local ratsnest tool is no longer active. |

|

Footprint placement tool: click on the board to open the footprint chooser, then click again after choosing a footprint to confirm its location. |

|

Route tracks / route differential pairs: These tools activate the interactive router and allow placing tracks and vias. The interactive router is described in more detail in the Routing Tracks section. |

|

Tune length: These tools allow you to tune the length of single tracks or the length or skew of differential pairs, after they have been routed. |

|

Add vias: place a standalone ("free") via without routing tracks. |

|

Add filled zone: Click to set the start point of a zone, then configure its properties before drawing the rest of the zone outline. Zone properties are described in more detail below. |

|

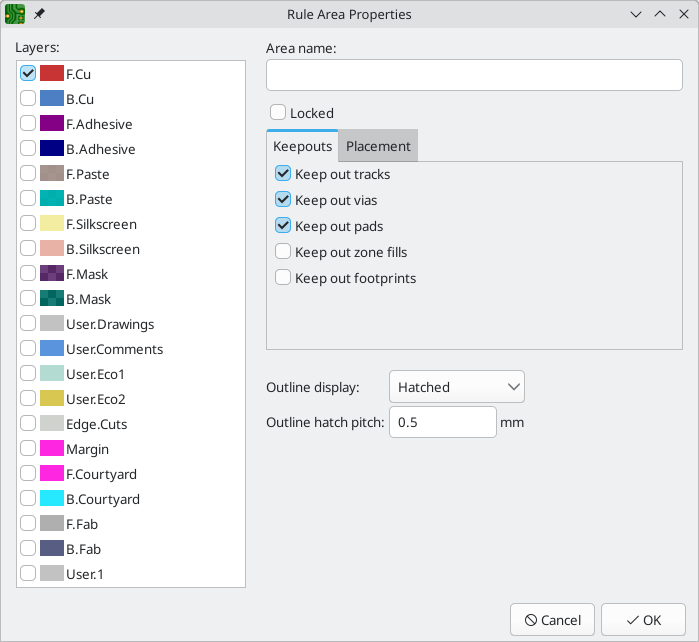

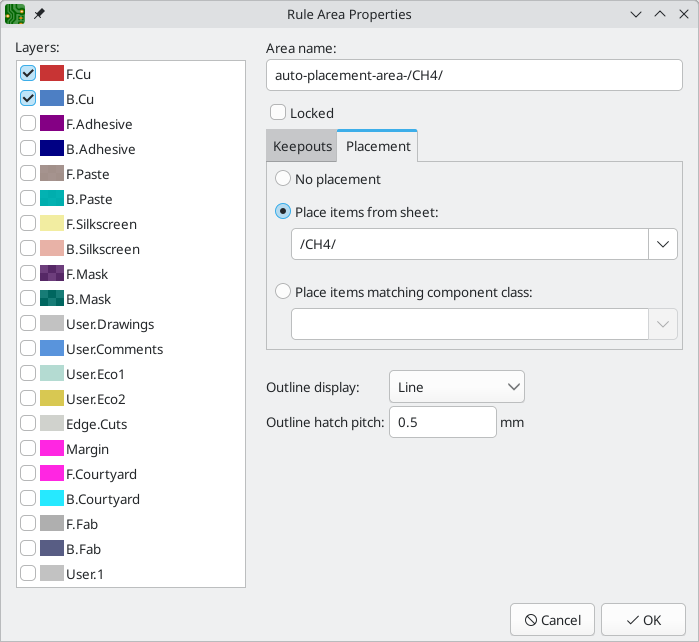

Add rule area: Rule areas, formerly known as keepouts, can restrict item placement and zone fills. You can also define named areas and apply specific custom DRC rules to them. |

|

Note: Lines are graphical objects and are not the same as tracks placed with the Route Tracks tool. |

|

Draw arcs: pick the center point of the arc, then the start and end points. By right clicking this button, you can change the arc editing mode between a mode that maintains the existing arc center and a mode that maintains the arc radius. |

|

Draw rectangles. Rectangles can be filled or outlines. |

|

Draw circles. Circles can be filled or outlines. |

|

Draw graphical polygons. Polygons can be filled or outlined. Note: Filled graphical polygons are not the same as filled zones: graphical polygons cannot be assigned to a net and will not keep clearance from other items. |

|

Draw bezier curves. Each click alternates between fixing a curve node and fixing the control handle for the node that was just placed. |

|

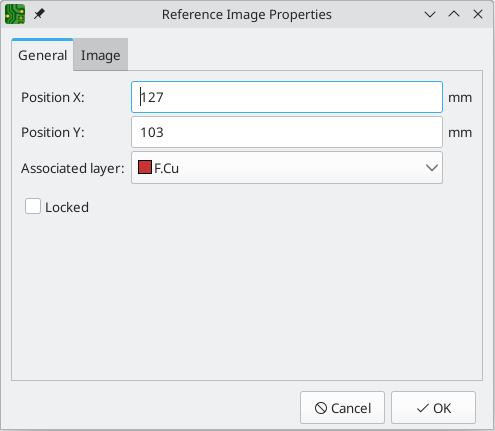

Add bitmap image for reference. Reference images are not included in fabrication outputs. |

|

|

|

|

|

|

|

|

|

Deletion tool: click objects to delete them. |

|

Set grid origin or drill/place origin (used for fabrication outputs). |

|

Interactively measure the distance between two points. |

Grids and snapping

When moving, dragging, and drawing board elements, you can make these operations snap to a grid or to snapping points on pads and other items. In complex designs, snap points can be so close together that it makes the current tool action difficult. Both grid and object snapping can be disabled while moving the mouse by using the modifier keys in the table below.

| On Apple keyboards, use the Cmd key instead of Ctrl. |

| 快捷键 | 效果 |

|---|---|

Ctrl |

关闭网格捕捉。 |

Shift |

关闭对象捕捉。 |

Tools only snap to objects on visible layers. You can reduce unwanted snapping points by hiding unneeded layers or using the single-layer view mode. Additionally, you can toggle between snapping to objects on all layers or only snapping to objects on the current layer by pressing Shift+S.

Snapping to different types of objects (pads, tracks, and graphics) can be configured in the Editing Options section of the PCB Editor preferences.

Snapping to graphical shapes

When working with graphic shapes like rectangles or arcs, such as when drawing shapes or when selecting a reference point for a move operation, many additional snapping points are available that let you snap to features of existing graphic shapes.

Available snapping points for graphic shapes include:

-

Endpoints and corners

-

Midpoints

-

Centers

-

Intersection points

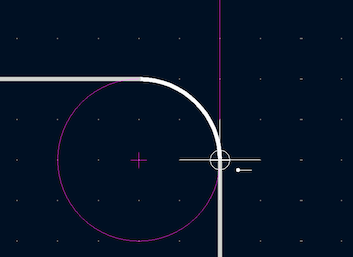

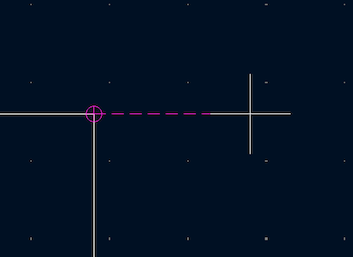

When you hover over a snap point with a shape tool active, a graphical icon will be shown that indicates a snapping point is active and explains the type of snapping point. Clicking will use that snapping point. Some shapes display auxiliary snapping lines that appear when you snap to part of that object. For example, line segments display an auxiliary line that continues the segment beyond its endpoint, and arcs display an auxiliary circle that completes the arc’s circumference. Auxiliary shapes can be used for snapping just like the original shape. An auxiliary line and circle are shown as a solid purple line in the screenshot below. The cursor indicates that the active snapping point is the endpoint of a line.

If you move the cursor away from the snapping point, a horizontal or vertical dashed line will appear, depending on the direction of motion. This indicates a horizontal or vertical projection from the snapping point, respectively. Following the line will maintain a position that is horizontally or vertically aligned to the original snap point. This projection is shown as a purple dashed line in the screenshot below.

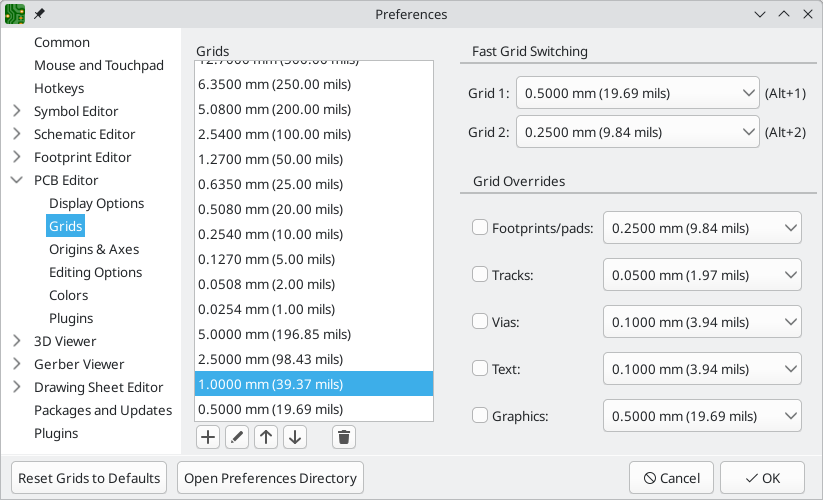

Grid settings

Interactive editing operations are snapped to the active grid. You can adjust the grid size using the grid dropdown in the top toolbar or by right-clicking and selecting a new grid from the list in the Grid submenu. Pressing the n or N hotkeys will cycle to the next and previous grid in the list, respectively.

You can also select a new grid or edit the available grids in the Grids pane of the preferences dialog. As a shortcut to reach this dialog, right click the ![]() button on the left toolbar and select Edit Grids….

button on the left toolbar and select Edit Grids….

In this dialog you can select an active grid from the list of grids, reorder the list of grids (![]() /

/ ![]() ), and add (

), and add (![]() ), remove (

), remove (![]() ), or edit (

), or edit (![]() ) grids. Grids defined in this dialog can have unequal X and Y spacing as well as an optional name. The grid spacing and name are specified when you create or edit a grid.

) grids. Grids defined in this dialog can have unequal X and Y spacing as well as an optional name. The grid spacing and name are specified when you create or edit a grid.

This dialog also lets you designate two grids from the list as "Fast Grids", which can be quickly selected using Alt+1 and Alt+2.

Finally, you can configure grid overrides for different types of objects. Grid overrides let you set particular grid sizes for different types of objects which will be used instead of the default grid when working with those objects. For example, you can set a 100 mil grid for footprints and pads while using smaller grids to finely position tracks, vias, and text. Grid overrides can be individually enabled and disabled in this dialog, or globally enabled and disabled using the ![]() button on the left toolbar (Ctrl+Shift+G).

button on the left toolbar (Ctrl+Shift+G).

To change the origin (zero point) of the grid, use Place → Grid Origin and click to place the origin in the canvas. This function is also available with the ![]() button in the right toolbar. Alternatively, you can enter explicit coordinates for the grid origin with Edit → Grid Origin….

button in the right toolbar. Alternatively, you can enter explicit coordinates for the grid origin with Edit → Grid Origin….

| The grid origin is one of several different origins in KiCad, which aren’t necessarily set to the same point. The grid origin is the point that the grid aligns to; shifting the grid origin also shifts every grid point. The page origin is an absolute origin which is always the top left corner of the drawing sheet. The drill/place file origin is a configurable point that can be used for fabrication outputs (Place → Drill/Place File Origin). Finally, the local origin is a quickly settable relative origin that current cursor location by pressing Space; the cursor coordinates relative to the local origin are displayed in the status bar. |

The visual appearance of the grid can also be customized in several ways. You can change the thickness of the grid markings, switch their shape (dots, lines, or crosses), and set the minimum displayed spacing in the Display Options page of the preferences dialog, and you can change the grid color in the Colors page of the preferences dialog.

The grid can be shown or hidden using the ![]() button on the left-hand toolbar. By default the grid is still active even if it is hidden, but this is configurable in the Display Options preferences page. There you can set the grid to be disabled when it is hidden or even disable the grid entirely.

button on the left-hand toolbar. By default the grid is still active even if it is hidden, but this is configurable in the Display Options preferences page. There you can set the grid to be disabled when it is hidden or even disable the grid entirely.

编辑对象属性

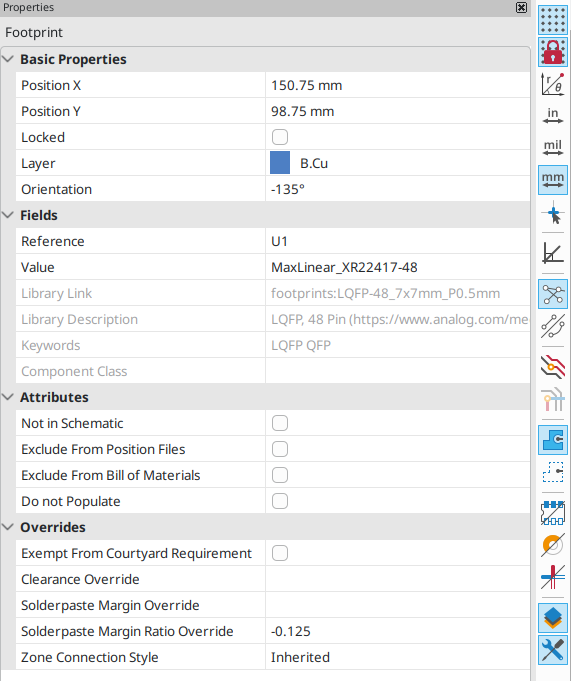

All objects have properties that are editable in a dialog. Use the hotkey E or select Properties from the right-click context menu to edit the properties of selected item(s). You can only open the properties dialog if all the items you have selected are of the same type. For many object types, like footprints, you can only edit the properties of a single item at one time. To edit the properties of multiple items at once, including items with different types, you can use the Properties Manager.

You can also view and edit item properties using the Properties Manager. The Properties Manager is a docked panel that displays the properties of the selected item or items for editing. If multiple types of items are selected at once, the properties panel displays only the properties shared by all of the selected item types.

Editing a property in the Properties Manager immediately applies the change. When multiple items are selected, property modifications are applied to each selected item individually, not to the whole selection as a group. For example, when changing the orientation of multiple items, each item is individually rotated around its own origin, not the group’s origin.

Show the Properties Manager with View → Panels → Properties or the ![]() button on the left toolbar.

button on the left toolbar.

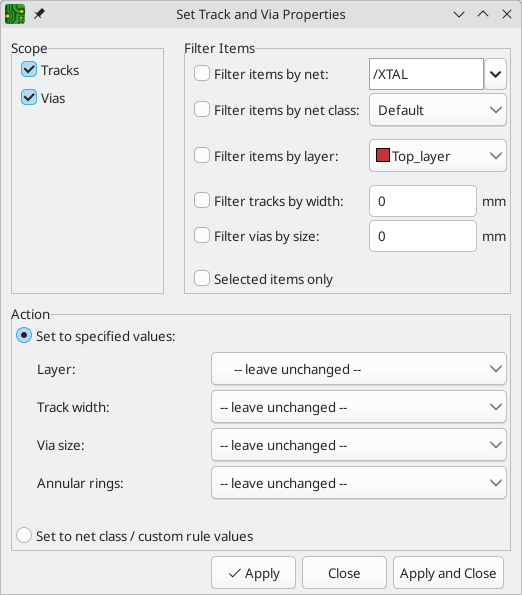

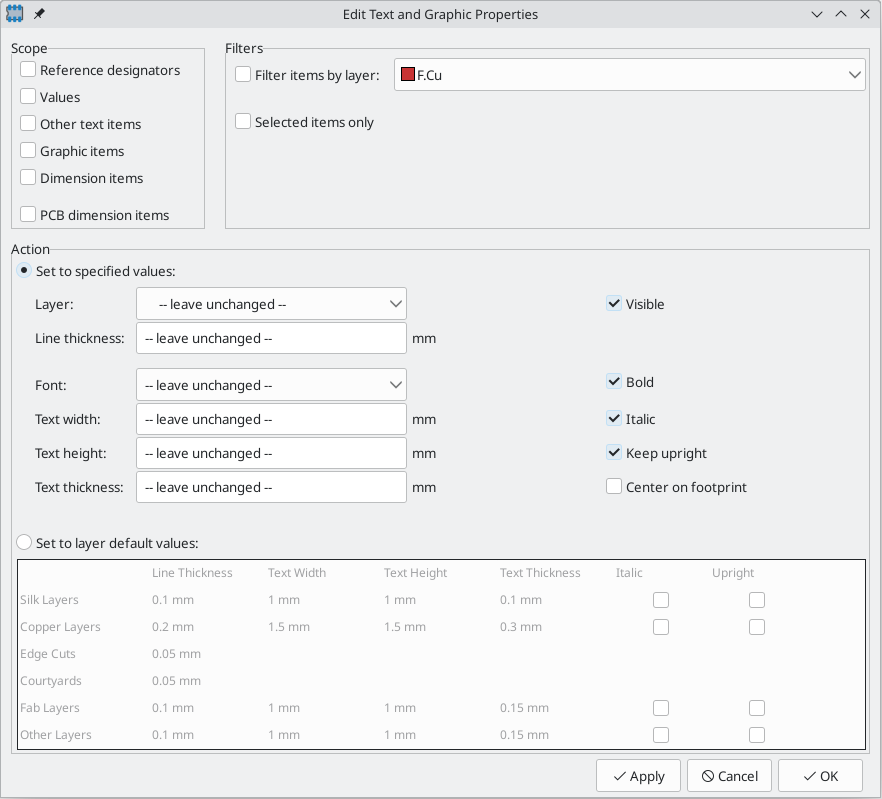

Several tools are available for editing properties of specific types of objects in bulk. For text and graphical items, including footprint fields and dimensions, you can use the Edit Text and Graphics Properties tool. Tracks and vias can be bulk-edited using the Edit Track and Via Properties tool. Teardrop properties can be edited with the Edit Teardrops tool.

In properties dialogs and many other dialogs, any field that contains a numeric value can also accept a basic math expression that results in a numeric value.

For example, a dimension may be entered as 2 * 2mm, resulting in a value of 4mm. Basic arithmetic operators as well as parentheses for defining order of operations are supported.

电路板边框 (Edge Cuts)

KiCad 使用 Edge.Cuts 层上的图形对象来定义电路板的边框。 边框必须是一个连续(封闭)的形状,但可以由不同类型的图形对象组成,如直线和弧,或者是一个单一的对象,如矩形或多边形。 如果没有定义电路板的边框,或者电路板的边框无效,那么一些功能,如 3D 查看器和一些设计规则的检查将无法发挥作用。

使用封装

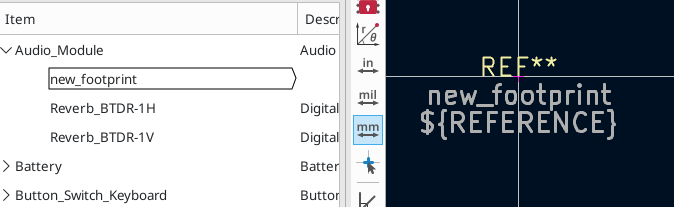

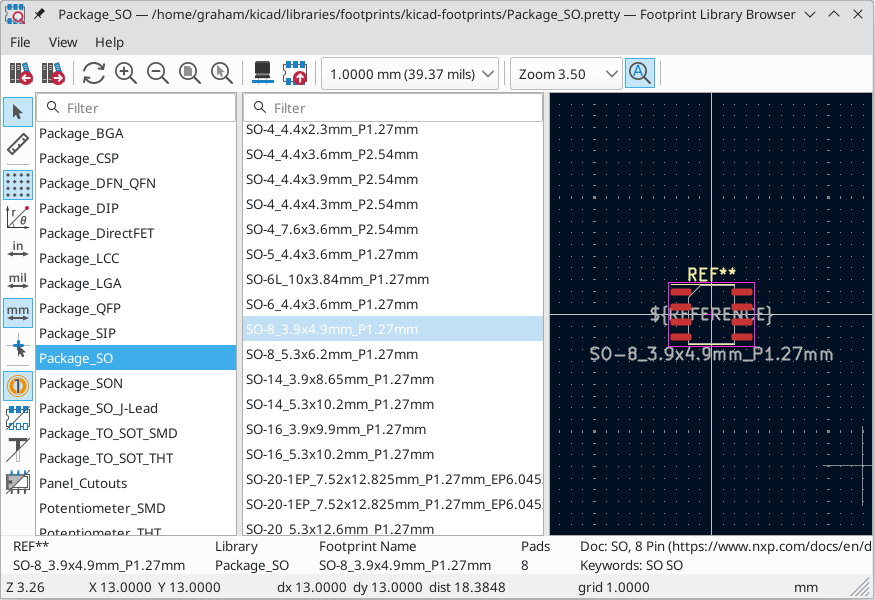

Adding footprints to the board

Footprints are automatically added to the board when the PCB is updated from the schematic. The footprint associated with each schematic symbol is added to the board if it is not already present, and each footprint pad is associated with the corresponding symbol pin’s net. Symbol pins are matched to footprint pads by pin/pad number.

When footprints are added to the board after an update from the schematic, they are clustered by schematic sheet and by geographical location in the schematic. They are initially attached to the cursor; you can place them by clicking in the desired location.

You can also add footprints to the board manually using the Add Footprint tool (A or the ![]() button).

button).

| Footprints added in this way will not be automatically associated with a symbol or have nets assigned to their pads, and subsequent updates from the schematic will remove these unassociated footprints unless the footprint is locked or the Delete footprints with no symbols option is unchecked in the Update PCB From Schematic dialog. For these reasons, it is usually recommended to avoid manually adding footprints to the board. Manually adding footprints is necessary for PCB-only workflows, and can also be useful for adding logos or other footprints that do not need a corresponding schematic symbol. |

Placing and moving footprints

Once footprints have been added to the board, you can reposition them in many ways.

The Move command (M) moves a footprint or a selection of footprints, ignoring any connected track segments that are not selected. No DRC checking is done when moving footprints with the Move command, although any footprint courtyards that collide with the moved footprint’s courtyard will be highlighted.

There is a reference point for the move operation, which is the point in the footprint which attaches to the cursor and therefore the point in the footprint that snaps to the grid and to other objects. The reference point during a move is determined by the location of the cursor when the Move command is initiated. If the cursor is over a pad, the pad’s center will be used as the reference point. If the cursor is not over a pad, the footprint’s anchor (coordinate origin point) will be used. To select an arbitrary snapping point, you can use the Move With Reference command instead of the regular Move command (right click → Positioning Tools → Move with Reference). After initiating the command, click on the desired reference point; KiCad will then begin the move with that point as the reference.

You can also use the Drag command (D) to move the selected footprint using the interactive router, maintaining all track connections to the footprint. Dragging footprints behaves like the Highlight Collisions router mode: obstacles will not be avoided or shoved, only highlighted. Ordinarily the router will prevent you from dragging a footprint into a position that violates DRC: when you click to commit a drag in a position that violates DRC, the footprint will return to its original position. To force a drag to be committed even if it violates DRC, Ctrl-click to commit the drag. Like the Move command, colliding courtyards are highlighted.

| Only tracks that end at the origin of the footprint’s pads will be dragged. Tracks that simply pass through the pad or that end on the pad at a location other than the origin will not be dragged. |

You can move a footprint to the opposite side of the board with the Flip command (F). Any parts of the footprint on a front layer will be swapped to the corresponding back layer, and vice versa.

Footprints can be rotated counter-clockwise using the R hotkey, or clockwise using Shift+R. By default, footprints are rotated by 90 degrees every time the rotate command is used, but you can configure the rotation angle step in Preferences → PCB Editor → Editing Options.

You can directly set a footprint’s exact absolute position, rotation angle, and PCB side using either the Footprint Properties dialog or the Properties panel.

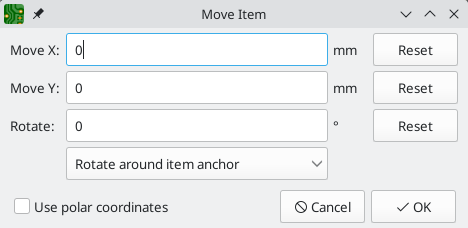

To reposition a footprint relative to its current position, use the Move Exactly tool (Shift+M). The dialog lets you specify an X and Y translation, as well as a rotation, that will be applied to the footprint. The rotation can be performed relative to either the footprint’s anchor, the local coordinate origin, or the drill/place origin. You can also use polar coordinates instead of Cartesian coordinates.

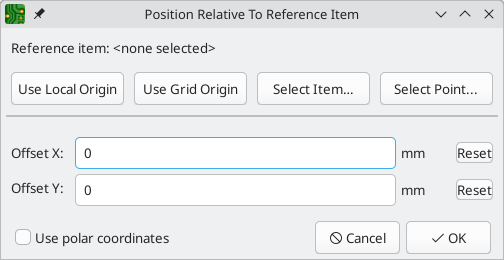

To position a footprint relative to another object, you can use the Position Relative tool (Shift+P). With this tool, you select a reference point for the move and specify an offset. The footprint is moved to the specified offset relative to the reference point. The reference point can be one of the following:

-

The local origin, which is set to the cursor position when you press Space.

-

The grid origin, which is configured in the Grids dialog.

-

The location of an arbitrary item on the board, such as a specific pad in a footprint. After clicking the Select Item… button, click on the desired board item in the canvas to set the reference point.

-

An arbitrary point in the canvas. After clicking the Select Point… button, click at the desired location to set the reference point. You can use object snapping to select a specific point in an object, such as the end of a graphic line.

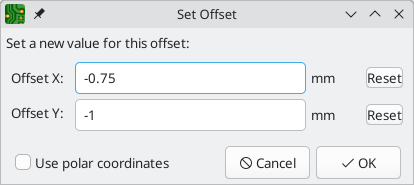

To position a footprint such that an arbitrary point in the footprint is positioned a certain distance from another arbitrary reference point, you can use the Position Interactively tool (right click a footprint → Positioning Tools → Position Interactively…).

This tool lets you interactively select two points that form the start and end of a position vector. The first point is a reference point in the footprint, and will move along with the footprint. The second point is a fixed reference that will remain stationary when the footprint is moved. The vector from the first point to the second point is shown graphically in the editing canvas. You can then give new X and Y (or polar) dimensions for the vector, which will move the footprint reference relative to the fixed reference such that the fixed reference is the specified distance from the footprint reference point. The dialog initially contains the vector dimensions before any move is performed, or in other words the initial distance between the footprint reference point to the fixed reference.

You can swap the position of two selected footprints using the Swap command (S). The first footprint is assigned the location, rotation, and board side of the second footprint, and vice versa. If there are more than two footprints selected, the locations are cycled: the last footprint gets the position of the first footprint, the first footprint gets the location of the second, and so on.

There are several convenience features that make it easier to find, select, and move specific footprints or footprints related to another footprint.

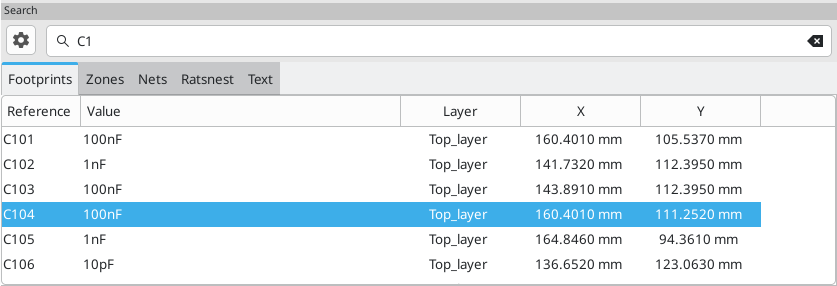

The Get and Move Footprint command (T) prompts you to choose a footprint from a list or by typing a reference designator. KiCad then attaches the chosen footprint to your cursor for a move operation.

There are two commands to select other footprints that need to be connected to the selected footprint but don’t yet have routed connections. The Select All Unconnected Footprints command (O) selects all footprints that have ratsnest lines to the currently selected footprints. The command can be executed repeatedly to further expand the selection based on the newly selected items. The Grab Nearest Unconnected Footprint command (Shift+O) selects the closest footprint with ratsnest lines to the currently selected footprint, and additionally begins to move it. If there are multiple footprints initially selected, the command will act like the Move Individually command described below, individually moving the closest unconnected footprint for each of the initially selected footprints.

You can select footprints based on their schematic sheet using the right click → Select → Items in Same Hierarchical Sheet command, which selects all other footprints that are in the same schematic sheet as the originally selected footprint.

If you want to move multiple selected footprints in sequence, use the Move Individually command (Ctrl+M). After triggering the command, KiCad will begin moving the first selected footprint. After you click to place the footprint, KiCad will immediately start moving the next footprint, in the same order that you selected the footprints. You can skip moving a footprint by pressing Tab, commit the current move and skip any remaining moves by double-clicking, or cancel all moves (including those already completed) by pressing Esc.

If you want to move a collection of footprints at once into one area, the Pack and Move Footprints command (P) closely packs the selected footprints together and moves them as a block.

| Move Individually and Pack and Move Footprints are useful in combination with other selection convenience features, such as cross-selection from the schematic or the advanced footprint selection features described above. For example, you could select a group of bypass capacitors in the Schematic Editor, switch to the PCB Editor where the corresponding footprints are now selected, and then use Move Individually to quickly place all of the bypass capacitor footprints close to their respective ICs. Alternatively, you could use one of the other selection tools, such as Select All Unconnected Footprints, to select many footprints from all over the board, then use Pack and Move Footprints to quickly put them all into a small area. |

Finally, KiCad can automatically place footprints onto the board. The auto-place function attempts to optimally place footprints to simplify ratsnest connections to other footprints. You can auto-place the selected footprints with Place → Auto-Place Footprints → Place Selected Footprints, or auto-place all footprints outside of the board outline with Place → Auto-Place Footprints → Place Off-Board Footprints.

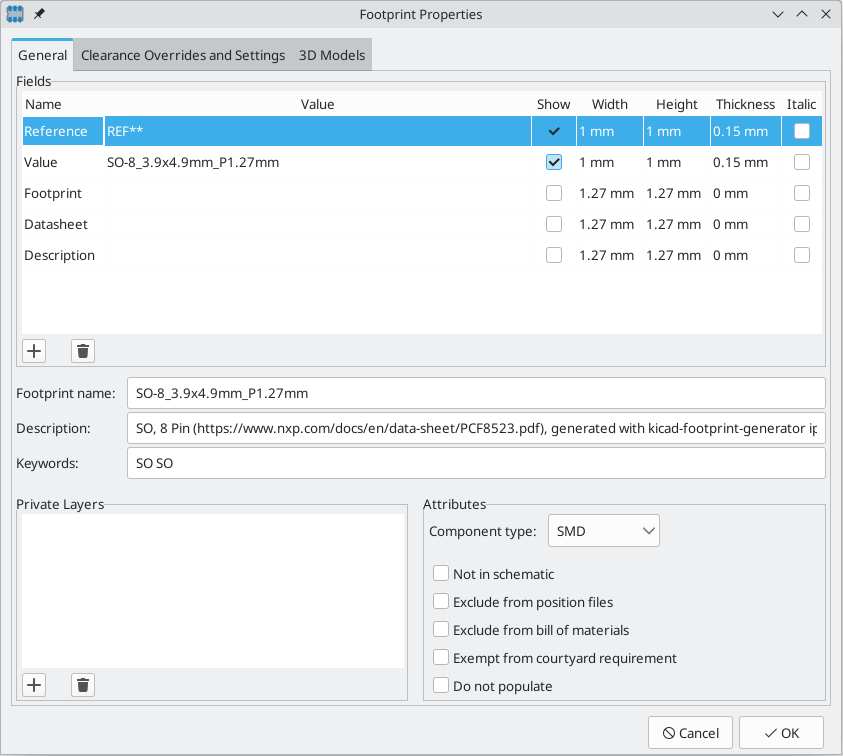

Editing Footprints

Footprints in the board can be individually edited, both in terms of their properties (fields, attributes, clearance settings, etc.) and in terms of their physical pads and graphics. Editing a footprint in the board only affects that particular instance of the footprint; it does not affect any other copies of that footprint in the board, and it does not affect the library footprint.

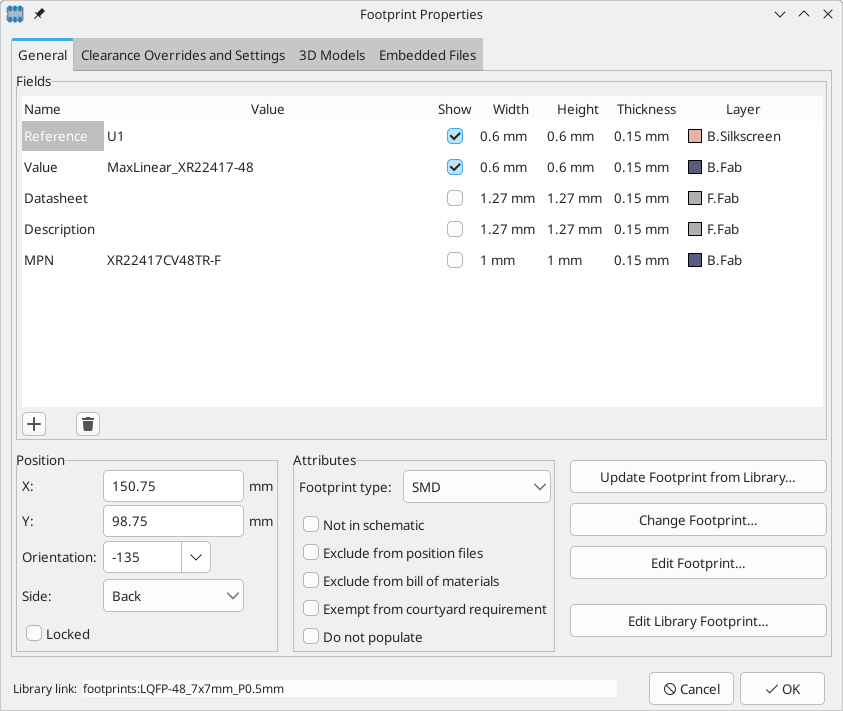

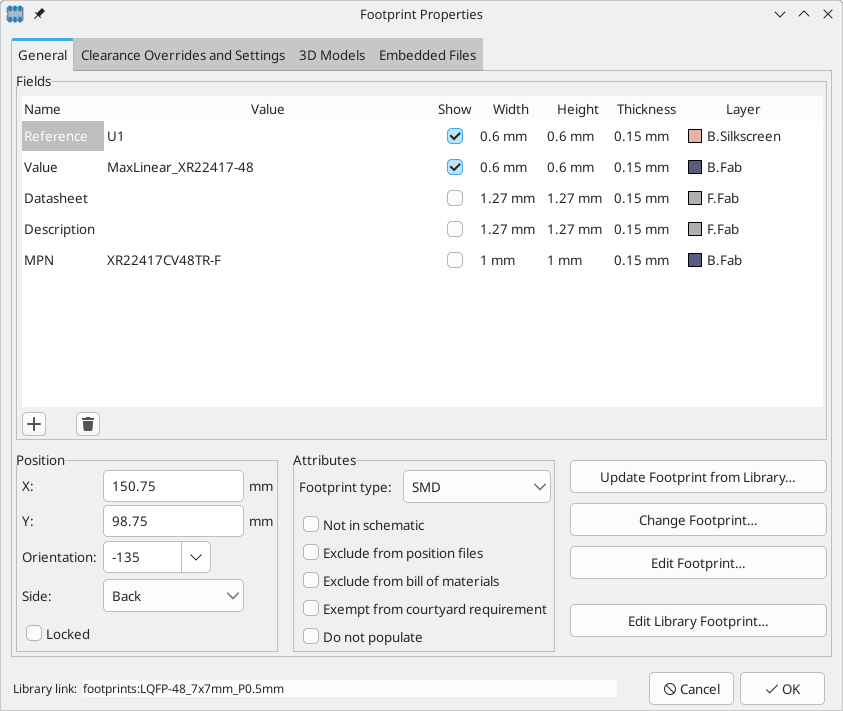

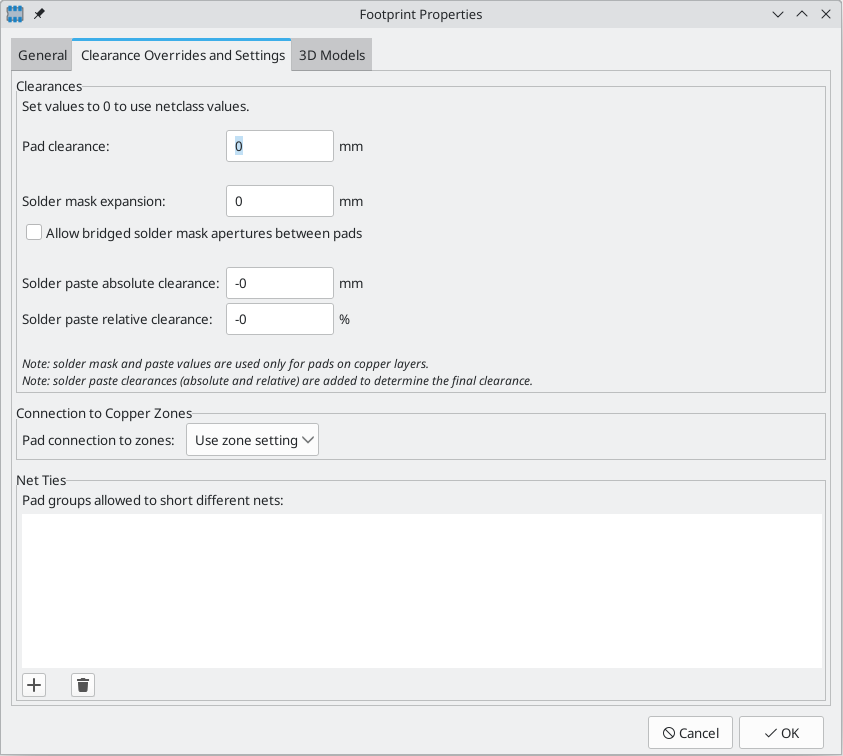

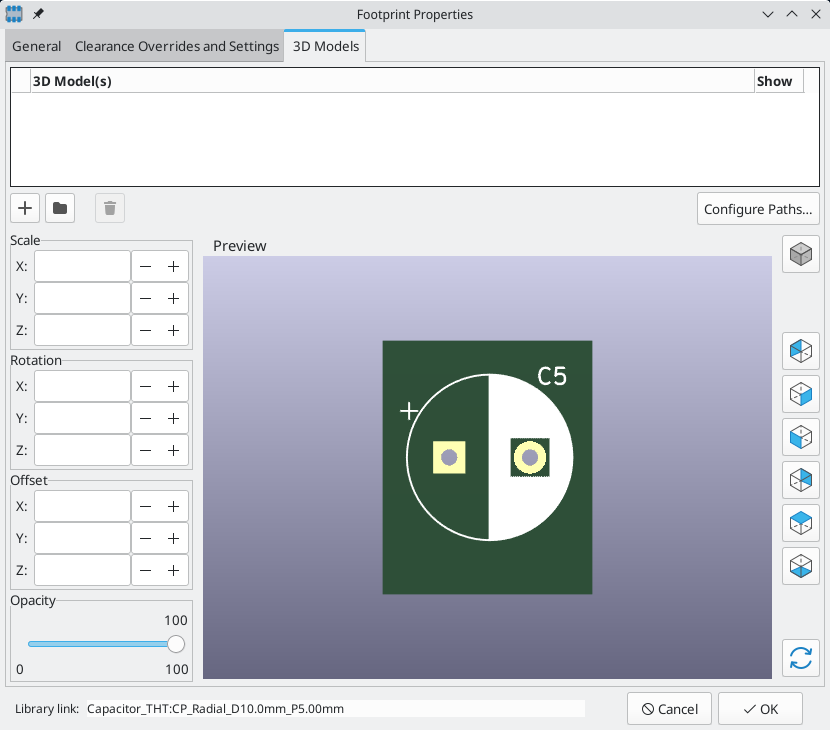

To edit the properties of a footprint in the board, open its properties dialog (E)

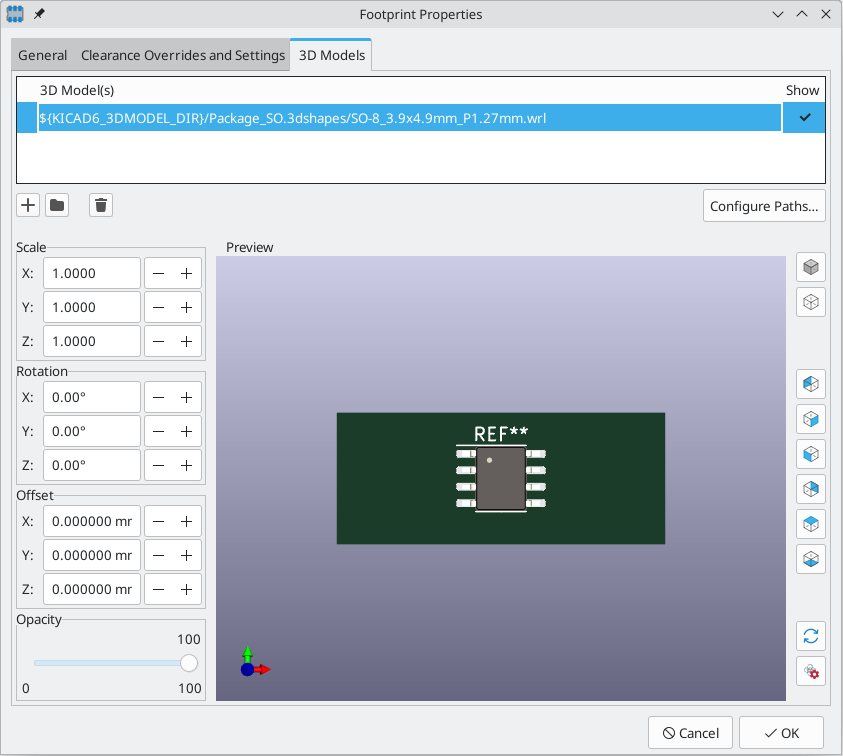

The majority of the settings in this dialog are the same as in the footprint editor. You can edit the footprint’s fields, attributes, clearance and zone connection settings, 3D models, and embedded files, as in the footprint editor. However, here you can also set the footprint’s position, orientation, and side. You can also update the footprint from the library, exchange it for a different footprint, or edit the footprint itself in the footprint editor.

To edit the footprint’s physical form, i.e. its pads and graphics, you need to use the footprint editor. There are two buttons for opening a footprint in the editor, depending on whether you want to edit a single copy of a footprint in the board or a footprint’s source copy in the library.

-

Edit Footprint… will open the specific instance of the footprint in the footprint editor. Editing this footprint will only affect this one instance of the footprint in the board. It will not affect other instances of the footprint in the board, and it will not affect the library copy of the footprint. You can also open a board footprint in the footprint editor by right clicking the footprint in the board and selecting Open in footprint editor (Ctrl+E).

-

Edit Library Footprint… will open the library copy of the footprint in the footprint editor. Editing the library copy of the footprint will edit the footprint in the footprint library, but will not immediately affect any instances of that footprint in the board. To update footprints in the board with changes to the library footprint, use the Update Footprint from Library… tool. Editing the library footprint in this way is equivalent to opening the footprint editor, opening the appropriate footprint in its library, and editing it.

The Update Footprint from Library… button is used to update the board’s copy of the footprint to match the copy in the library. The Change Footprint… button is used to swap the current footprint to a different footprint in the library. These functions are described later.

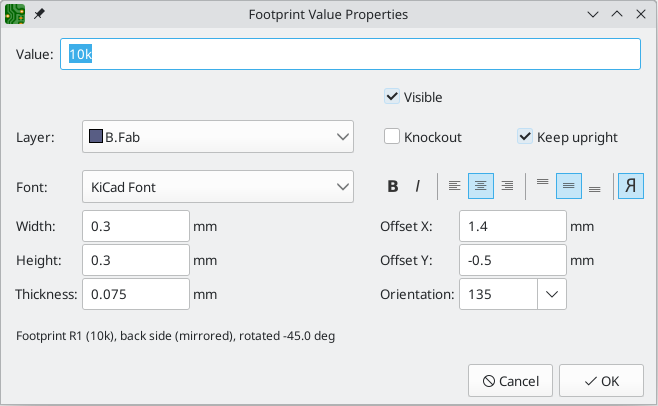

Editing footprint fields

An individual symbol text field can be edited directly with the E hotkey (with a field selected instead of a footprint) or by double-clicking on the field.

The options in this dialog are the same as those in the full Footprint Properties dialog, but are specific to a single field.

Only footprint fields can be edited this way in the board editor. Unlike fields, Footprint text is a graphic object that can only be edited or moved in the footprint editor.

| In versions of KiCad before version 8.0, footprint fields did not exist. Instead, footprint text could be edited directly in the board editor. In KiCad 8.0, footprint text is not editable in the board editor and can only be edited in the footprint editor. |

Updating and exchanging footprints

When a footprint is added to the board, KiCad embeds a copy of the library footprint in the board so that the board is independent of the system libraries. Footprints that have been added to the board are not automatically updated when the library changes. Library footprint changes are manually synced to the board so that the board does not change unexpectedly.

| You can use the Compare Footprint with Library tool to inspect the differences between a footprint in a board with its corresponding library footprint. |

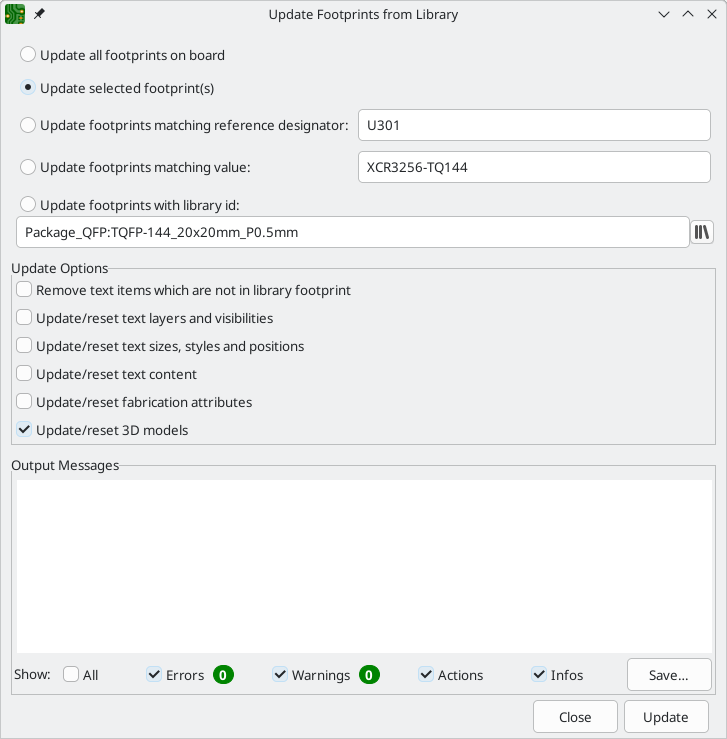

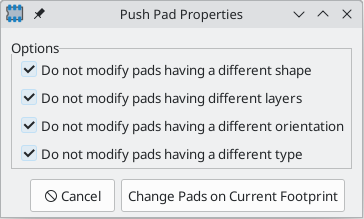

To update footprints in the board to match the corresponding library footprint, use Tools → Update Footprints from Library…, or right click a footprint and select Update Footprint…. You can also access the tool from the footprint properties dialog.

The top of the dialog has options to choose which footprints will be updated. You can update all footprints on the board, update only the selected footprints, or update only the footprints that match a specific reference designator, value, or library identifier. The reference designator and value fields support wildcards: * matches any number of any characters, including none, and ? matches any single character.

The middle of the dialog has options to control what parts of the footprint will be updated. You can select specific fields to update or not update, which properties of the fields to update (text content, visibility, size and style, and position), and how to handle fields that are missing or empty in the library footprint. You can also choose whether to update footprint attributes, such as footprint type, not in schematic, exclude from position files / bill of materials, exempt from courtyard requirement, and do not populate.

The bottom of the dialog displays messages describing the update actions that have been performed.

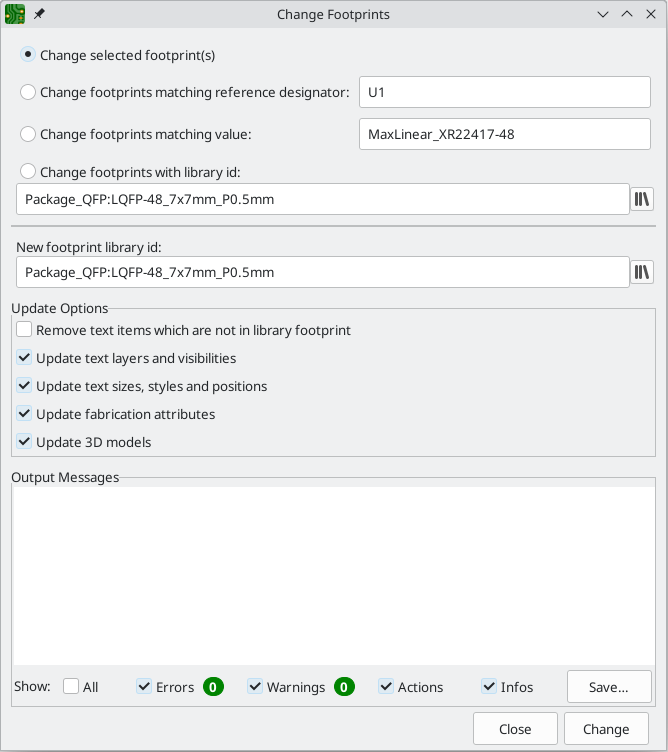

To change an existing footprint to a different footprint, use Edit → Change Footprints…, or right click an existing footprint and select Change Footprint…. This dialog is also accessible from the footprint properties dialog.

The options for the Change Footprints dialog are very similar to the Update Footprints from Library dialog.

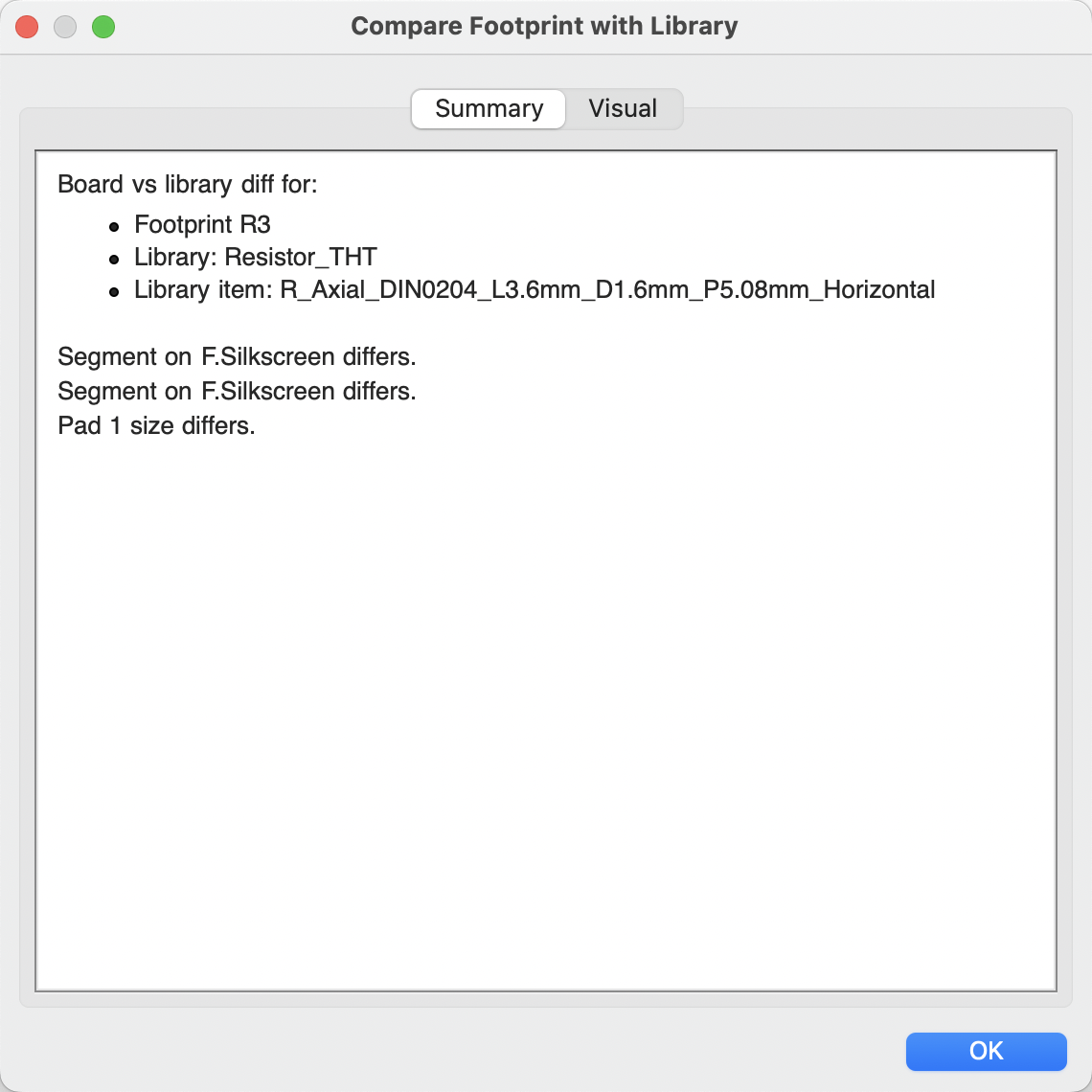

Comparing footprints between board and library

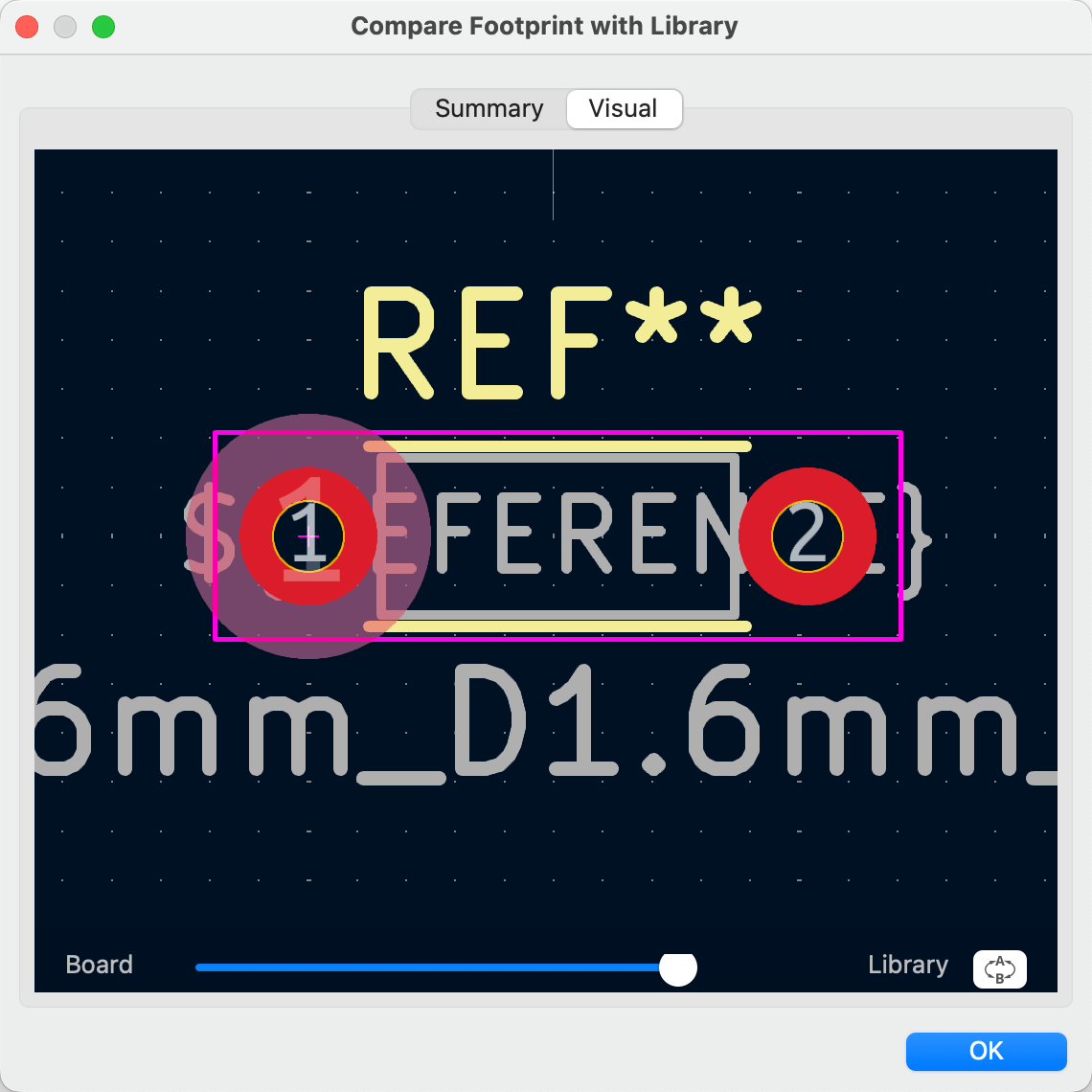

When a footprint in a board diverges from the corresponding footprint in the original footprint library, you can use the Compare Footprint with Library tool to inspect the differences between the two versions of the footprint. Run the tool using Inspect → Compare Footprint With Library.

The Summary tab shows the name of the footprint, including its library and board reference designator, and provides a list of the differences between the board and library versions of the footprint.

The Visual tab shows a visual comparison of the board and library versions of the footprint. This can be used as a visual diff tool.

By default, the comparison displays both versions of the footprint superimposed on each other. To see the changes more easily, you can drag the slider at the bottom of the tab to the right to emphasize the library version of the footprint in the superimposed view (making the board version of the footprint more transparent) or drag it to the left to emphasize the board version (making the library version more transparent). At the far right and left ends of the slider, the board and library versions of the footprint, respectively, are fully hidden. It may be helpful to drag the slider back and forth to see the changes more clearly.

You can press the A/B button, or use the / hotkey, to quickly toggle back and forth between the board and library versions.

The screenshot above shows a visual comparison with the board version of the footprint deemphasized. Looking at pad 1 on the left, you can see a large, partially transparent pad (from the board footprint) surrounding a fully opaque, smaller pad (from the library footprint). This indicates that the pad was enlarged in the board version of the footprint, or shrunk in the library version of the footprint.

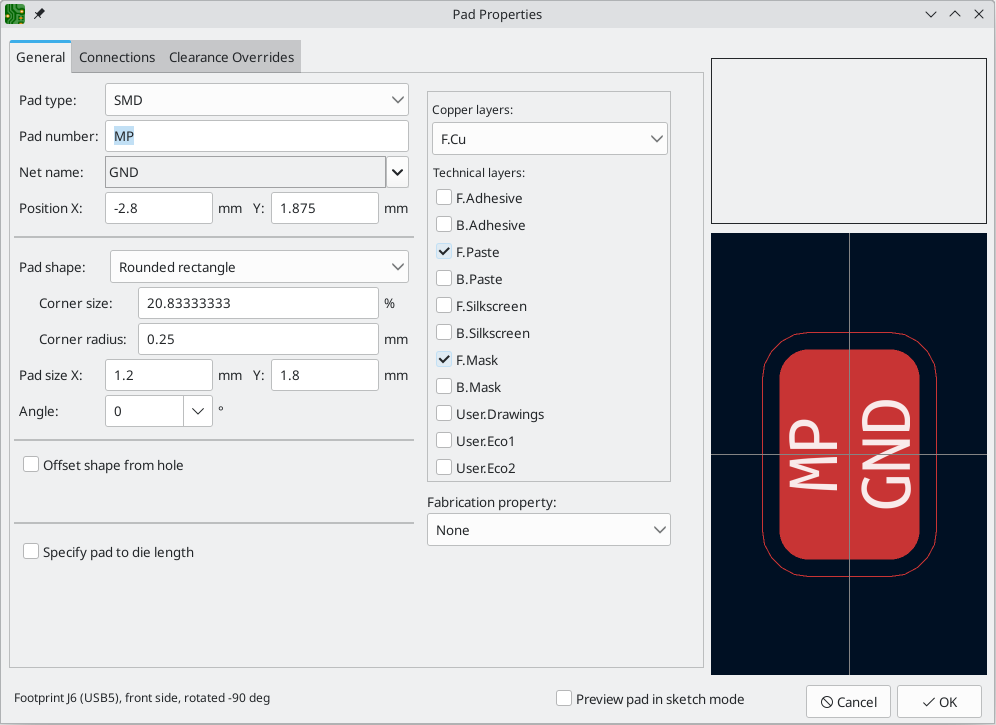

使用焊盘

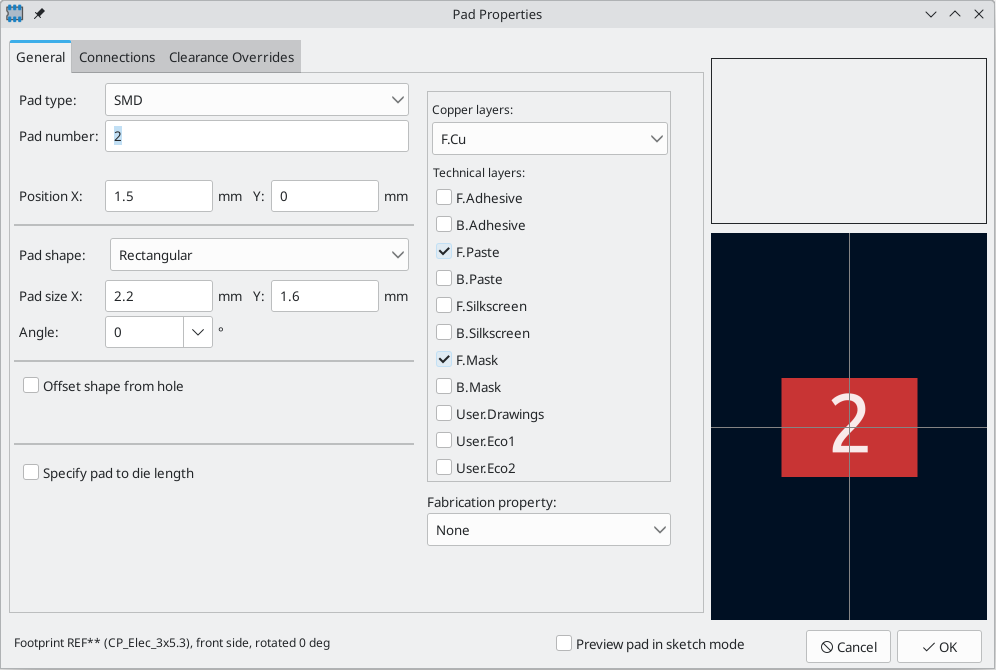

在将封装放置在电路板上之后,可以检查和编辑封装的每个单独的焊盘的属性。 换句话说,如果库中的封装设计不合适,就可以在电路板上封装的特定实例中覆盖单个封装焊盘的设计。 例如,你可能希望为一个需要在特定设计中保持不焊接的焊盘去除锡膏孔,或者你可能希望移动一个轴向引线电阻的通孔焊盘的位置,以适应特定的设计。

| 默认情况下,所有封装焊盘的位置都被锁定,因此可以编辑焊盘属性,但不能移动焊盘相对于封装其他部分的位置。 焊盘可以被解锁以允许自由移动,这对某些应用很有用(如具有不同引线位置的通孔封装),但通常不建议用于表面贴装封装。 |

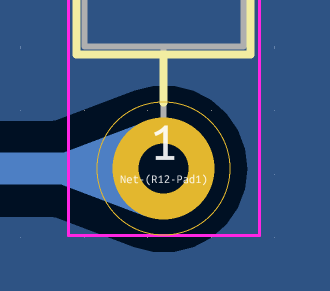

当一个焊盘被选中时,焊盘属性对话框将通过上下文菜单或默认的快捷键 E 打开。 请注意,KiCad 认为如果你在焊盘附近点击,你可能是想选择整个封装而不是单个焊盘。 要选择单个焊盘,请确保在焊盘区域内点击,或者关闭选择过滤器中的 "封装" 设置(并确保 "焊盘" 设置打开),以防止意外地选择整个封装而不是特定的焊盘。

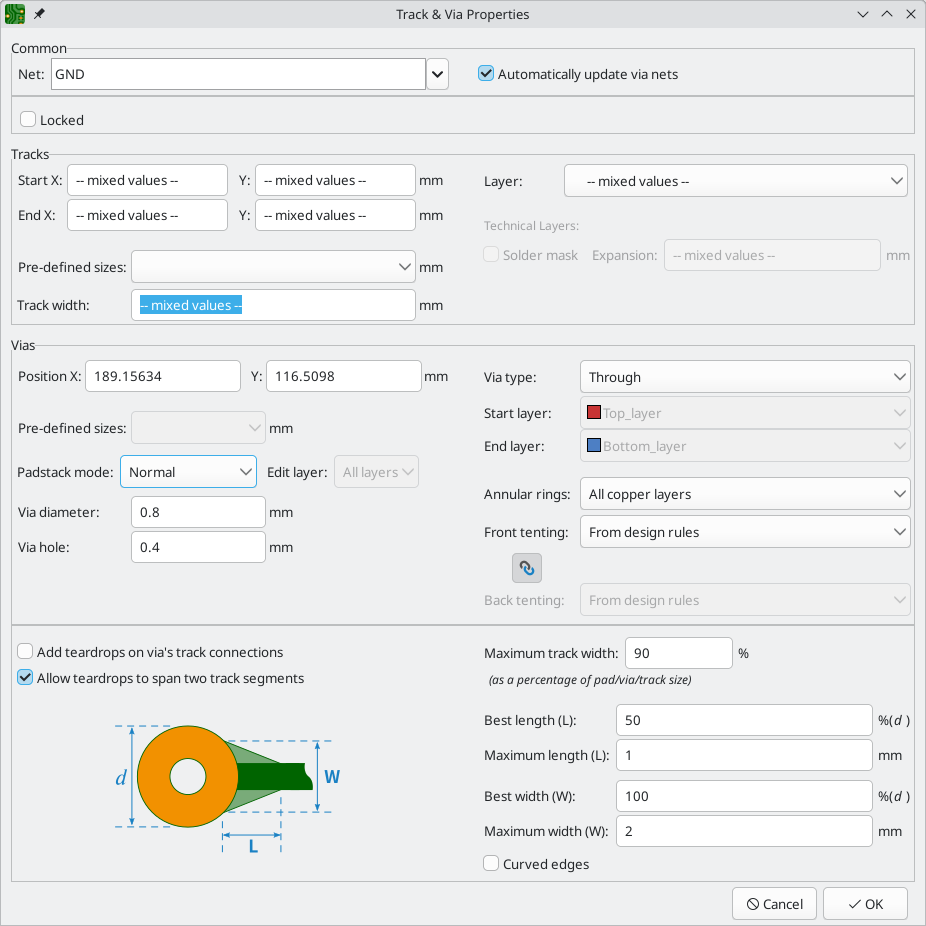

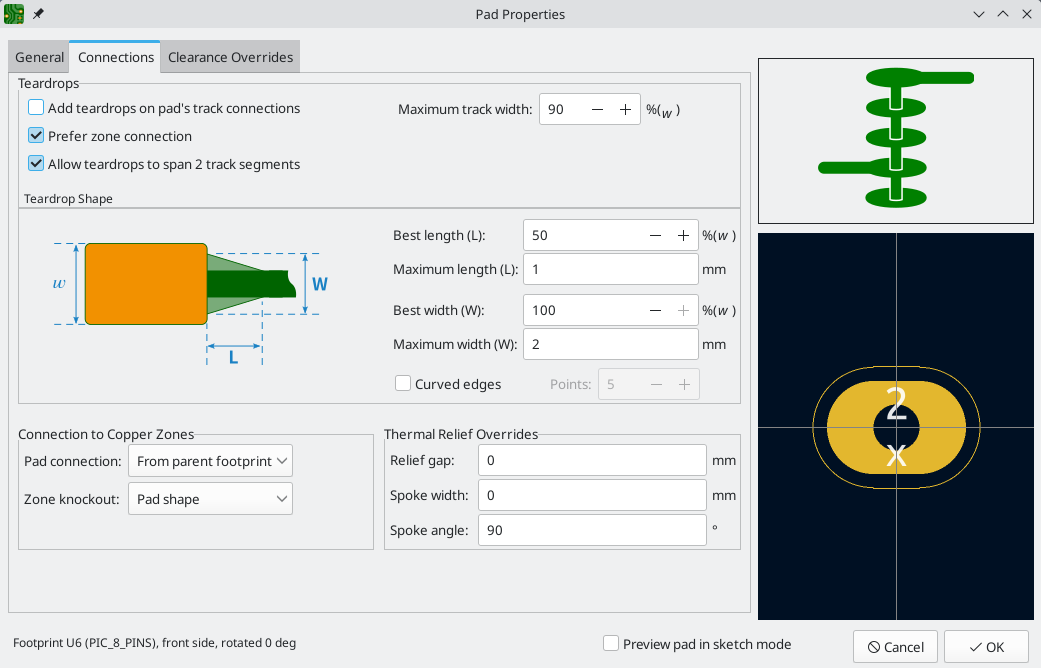

This dialog lets you edit the physical properties of the pad, including size and shape. You can also modify how the pad connects to other objects on the board, including clearance properties, teardrops, and thermal reliefs.

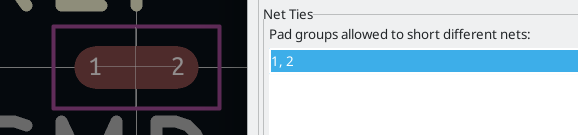

This dialog is the same as the pad properties dialog in the footprint editor, except that here you can also manually assign a net to a pad using the net name selector. The remaining options are explained in the Footprint Editor documentation.

| While you can manually assign nets to pads in the PCB editor, this is not a typical workflow. Usually net-to-pad connections are defined by the schematic and then transferred to the PCB editor. |

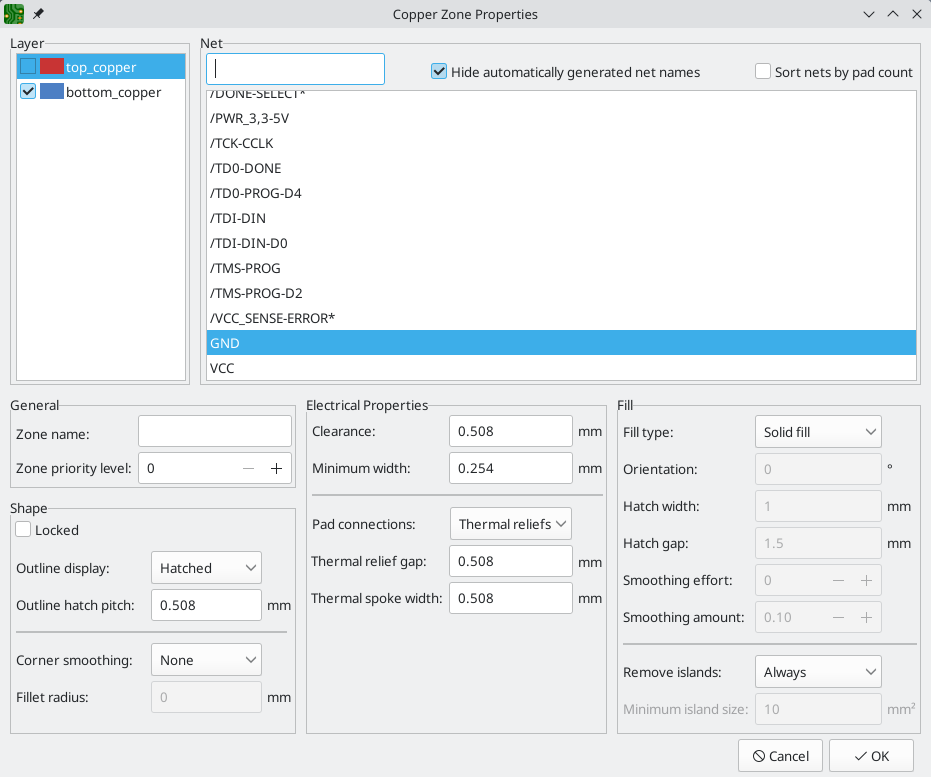

使用敷铜

敷铜区域,有时也被其他 EDA 工具称为铺铜或覆铜,是分配给一个特定网络的实心或网格状的铜箔区域,敷铜区域会自动保持与其他铜对象的间隙。 敷铜区域通常用于填充板层(或板层的一部分)上的所有自由空间,以创建接地和电源平面,承载大电流,或提供屏蔽。

| 一些 EDA 工具有单独的工具用于创建 "平面层" 及在信号层上创建敷铜区域。 在 KiCad 中,敷铜工具用于这两种应用。 |

区域是由一个多边形的 边框 来定义的,它定义了敷铜区域的最大范围。 这个边框并不代表实物铜,也不会出现在导出的制造数据中。 每次修改边框或边框内的任何对象时,必须 填充 该敷铜区域。 填充过程可以在单个敷铜区域上运行,也可以在电路板的所有区域上运行(默认快捷键 B)。 敷铜区域可以 不填充(默认快捷键 Ctrl+B),以提高性能并减少编辑大型电路板时的视觉混乱。

| By default, zone filling is a manual process rather than occurring every time an object changes that would result in a change to the zone copper. This is because zone filling can be a slow process on older computers or very large designs. It is important to make sure zone fills are up-to-date before generating outputs. KiCad will check that zones have been updated and warn you before generating outputs or running DRC when zones have not yet been refilled. You can optionally enable automatic zone-filling in the Preferences dialog (PCB Editor → Editing Options → Miscellaneous → Automatically refill zones). |

要绘制一个敷铜区域,请点击右侧工具栏的 “添加敷铜区域” 工具(![]() ),或者使用默认的快捷键 Ctrl+Shift+Z。 点击选择敷铜区域边框的第一个点。 敷铜区域属性对话框将出现,允许你选择敷铜区域的网络和其他属性。 这些属性可以在任何时候进行编辑,所以一开始正确选择它们并不是关键。 接受该对话框,继续放置点来定义敷铜区域的边框。 要完成这个区域,请双击来设置最后一个点。敷铜区域边框点可以像图形多边形一样进行修改,通过拖动方形手柄来移动一个角,或者拖动圆形手柄来移动一条边。 要编辑该敷铜区域的属性,请使用快捷键 E 或从上下文菜单中选择 “属性”。

),或者使用默认的快捷键 Ctrl+Shift+Z。 点击选择敷铜区域边框的第一个点。 敷铜区域属性对话框将出现,允许你选择敷铜区域的网络和其他属性。 这些属性可以在任何时候进行编辑,所以一开始正确选择它们并不是关键。 接受该对话框,继续放置点来定义敷铜区域的边框。 要完成这个区域,请双击来设置最后一个点。敷铜区域边框点可以像图形多边形一样进行修改,通过拖动方形手柄来移动一个角,或者拖动圆形手柄来移动一条边。 要编辑该敷铜区域的属性,请使用快捷键 E 或从上下文菜单中选择 “属性”。

Layer: A single zone object can create filled copper on one or more copper layers. Check the box next to each copper layer that this zone outline should fill on. The copper on each layer will be filled independently, but all layers will share the same net.

Net: Select the electrical net that the zone copper should be connected to. It is possible to create zones with no net assignment. Zones with no net will keep clearance from any copper objects on any net.

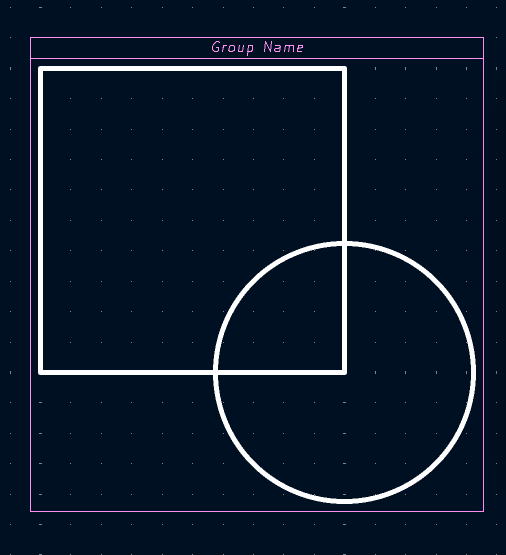

Zone name can be used to assign a specific name to a zone. This name can be used to refer to the zone in custom DRC rules.

Zone priority level determines the order in which multiple zones on a single layer are filled. The highest priority level zone on a given layer will be filled first. Lower-priority zones will keep clearance to the filled areas of higher-priority zones. Two zones on the same layer with the same priority level will overlap (short-circuit) with each other, unless they are assigned different nets. When two zone outlines with the same priority and different nets touch, one zone will maintain clearance to the other so that they don’t short.

Locked controls whether or not the zone outline object is locked. Locked objects may not be manipulated or moved, and cannot be selected unless the Locked Items option is enabled in the Selection Filter panel.

Outline display controls how the zone outline is drawn on screen. In Line mode, only the border lines of the outline are drawn. In Hatched mode, hatch lines are drawn on the inside of the outline border for a short distance, to make the zone outline more apparent. In Fully Hatched mode, hatch lines are drawn across the entire inside of the zone outline.

Corner smoothing controls the behavior of the filled copper areas at corners of the outline. Corners can be smoothed by a chamfer or fillet, or can extend all the way to the outline corner if smoothing is disabled. The chamfer or fillet size is configurable when those modes are selected.

| 默认情况下,倒角和圆角不会被添加到区域边框的内角,因为这将导致填充的铜延伸到边框之外。 如果需要光滑的内角,请在电路板设置对话框的约束部分启用 允许敷铜区域边框外的圆角 选项。 |

Clearance controls the minimum clearance the filled areas of this zone will keep from other copper objects. Note that if two clearance values are in conflict, the larger clearance value will be used. For example, if a zone is set to use 0.2mm clearance but its netclass is set to use 0.3mm clearance, the result will be an 0.3mm clearance.

Minimum width controls the minimum size of narrow necks of copper created inside the zone. Any copper areas that would be below this minimum width are removed during the filling process.

Pad connection controls the way that the filled zone areas will connect to footprint pads on the same net. Solid connections will result in the copper completely overlapping the pads. Thermal reliefs will result in small copper spokes connecting the pad to the rest of the copper zone, increasing the thermal resistance between the pad and the rest of the zone. This can be useful for hand soldering. Reliefs for PTH will apply thermal reliefs to plated through-hole pads and use solid connections for surface mount pads. None will result in the zone not connecting to any pads on the same net.

Thermal relief gap controls the distance maintained between any pad and the copper zone when the pad connection mode is set to generate thermal reliefs.

Thermal spoke width controls the width of the "spokes", or short copper segments connecting the pad to the rest of the copper zone.

Fill type controls how the copper zone is filled: the default is solid fill, which will result in copper filling in all available space within the zone outline. The zone can also be set to fill a hatch pattern, which will fill the area with a pattern that contains less copper. This can be useful for flexible printed circuits and other specialty applications.

Orientation controls the angle of the hatch pattern lines. An orientation of 0 degrees will result in the hatch pattern using horizontal and vertical lines.

Hatch width controls the width of each line in the hatch pattern.

Hatch gap controls the distance between each line in the hatch pattern.

Smoothing effort controls the style of smoothing applied to the hatch pattern. A value of 0 will result in no smoothing, and a value of 3 will result in the finest smoothing. Higher values will result in longer processing time and larger Gerber files.

Smoothing amount is a ratio that controls the size of the smoothing chamfers or fillets that are generated when smoothing effort is set to a value other than 0. An amount of 0.0 results in no smoothing, and a value of 1.0 results in maximum smoothing (in other words, a chamfer or fillet equal to half of the hatch gap).

Remove islands controls the behavior of isolated copper areas, also called islands, after the initial zone fill. When this is set to always, isolated areas inside the zone are removed. When set to never, isolated areas are left alone, and will result in copper areas that are not connected to the rest of the net. When set to below area limit, a minimum island size can be specified, and islands below this threshold will be removed.

| 无论 移除死铜 设置如何,死铜都不会从没有电气连接的敷铜区域中移除。 换句话说,仅可以从具有至少一个电气连接的敷铜中移除死铜。 |

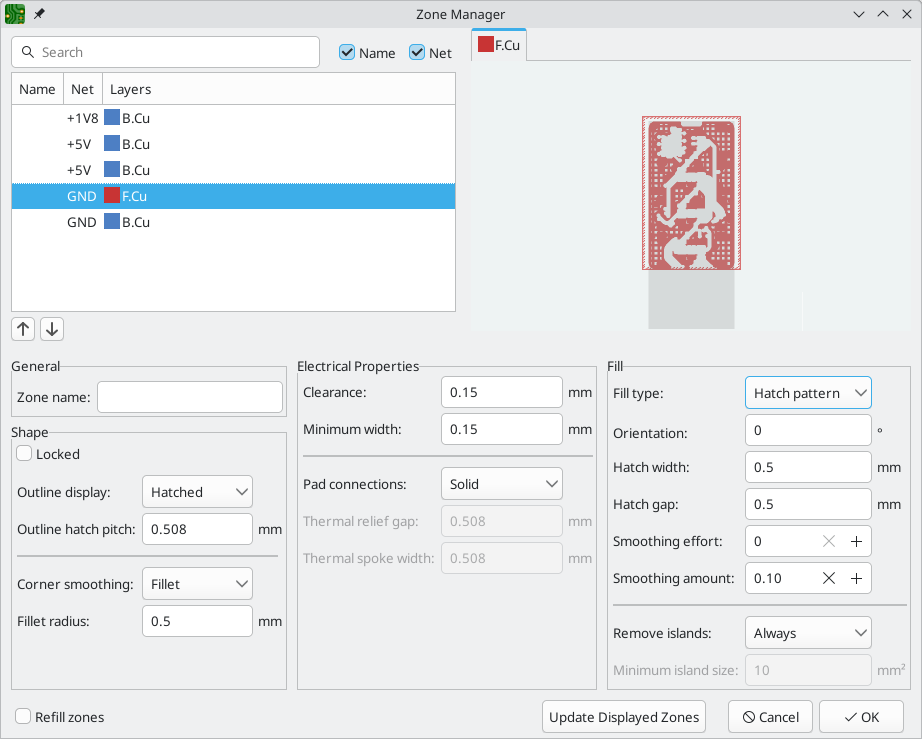

Managing zones

Instead of editing a single zone with the Zone Properties dialog, you can use the Zone Manager tool to you view, edit, and prioritize all zones in the board at once. To run the Zone Manager, click Tools → Zone Manager.

The top left of the dialog shows a list of all zones in the board, displaying the name (if any), net, and layers for each zone. The order of the zones in the list reflects the priority of each zone: higher priority zones are higher in the list. To change the priority of a zone, use the ![]() and

and ![]() buttons to move it up or down in the list. You can filter the list of zones by typing into the filter box. The filter matches against the zones' name and/or net, depending on which filter options are enabled.

buttons to move it up or down in the list. You can filter the list of zones by typing into the filter box. The filter matches against the zones' name and/or net, depending on which filter options are enabled.

Selecting a zone in the list shows a preview of that zone in the top right. If the selected zone spans multiple layers, each layer is shown individually. You can preview each layer by clicking the appropriate layer tab above the preview.

The bottom part of the dialog shows the settings for the selected zone, which are explained above. You can preview the new settings by clicking the Update Displayed Zones button, which updates the zone preview without affecting the board. Changing the properties of a zone in the Zone Manager will not update the board until you press OK. If the Refill zones option is enabled, all zones will be refilled when you accept the dialog. If Refill zones is not enabled, zones will not be refilled until you manually refill them.

布线

KiCad 具有交互式布线器的功能:

-

Allows manual or guided (semi-automatic) routing of single tracks and differential pairs

-

可通过以下方式修改现有设计:

-

拖动已有导线时进行重新布线

-

拖动封装时对连接到封装焊盘的导线进行重新布线

-

-

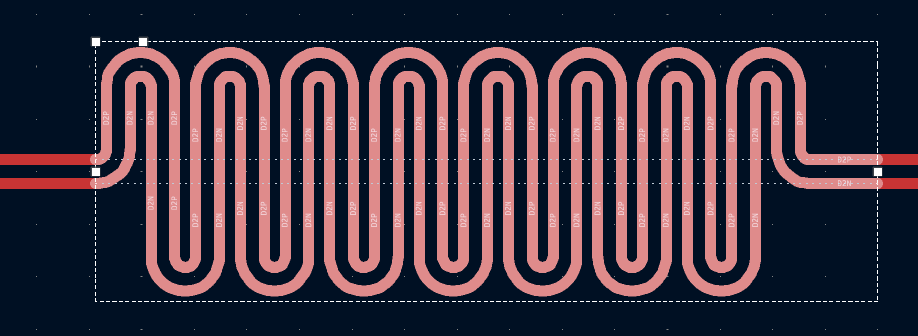

允许通过插入蛇形线

+来调整布线长度和差分对的偏移(相位) 为具有严格时序要求的设计调整布线形状

默认情况下,布线器在放置布线时遵循配置的设计规则:新布线的尺寸(宽度)将取自设计规则。在确定新布线和过孔的放置位置时,布线器将遵循设计规则中设置的铜间隙。 如果需要的话,可以通过使用高亮冲突布线器模式,或打开布线器设置中的 “允许 DRC 违规” 选项来禁用这种行为(见下文)。

The router has three modes that can be selected at any time in the Interactive Router Settings dialog. The router mode is used for routing new tracks, but also when dragging existing tracks using the Drag (hotkey D) command. These modes are:

-

Highlight Collisions: in this mode, most of the router features are disabled and routing is fully manual. When routing, collisions (clearance violations) will be highlighted in green and the newly-routed tracks cannot be fixed in place if there is a collision unless the Allow DRC Violations option is turned on. In this mode, up to two track segments may be placed at a time (for example, one horizontal and one diagonal segment).

-

Shove: in this mode, the track being routed will walk around obstacles that cannot be moved (for example, pads and locked tracks/vias) and shove obstacles that can be moved out of the way. The router prevents DRC violations in this mode: if there is no way to route to the cursor position that does not violate DRC, no new tracks will be created.

-

Walk Around: in this mode, the router behaves the same as in Shove mode, except no obstacles will be moved out of the way.

Which mode to use is a matter of preference. For most users, we recommend using Shove mode for the most efficient routing experience or Walk Around mode if you do not want the router to modify tracks that are not being routed. Note that Shove and Walk Around modes always create horizontal, vertical, and 45-degree (H/V/45) track segments. If you need to route tracks with angles other than H/V/45, you must use Highlight Collisions mode and enable the Free Angle Mode option in the Interactive Router Settings dialog.

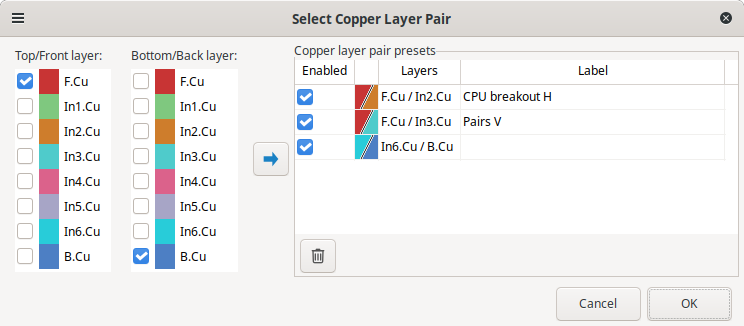

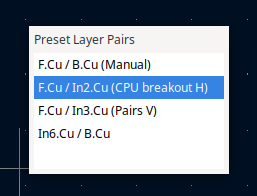

There are four main routing functions: Route Single Track, Route Differential Pair, Tune length of a single track, and Tune skew of a differential pair. All of these are present in both the Route menu dropdown (individually) on the top toolbar and the drawing toolbar in two overloaded icons on the drawing toolbar on the right. The use of the overloaded icons is described above. One is for the two Route functions and one is for the two Tune functions. In addition, the Route menu allows the selection of Set Layer Pair and Interactive Router Settings.

要进行布线布线,请点击布线 ![]() 图标(从绘图工具栏或从顶部工具栏 布线 菜单中)或使用快捷键 X。 点击一个起始位置,选择要布线的网络,并开始布线。 布线的网络会自动高亮显示,网络允许的间隙会在当前布线的周围用灰色的轮廓表示。 可以通过改变 "偏好设置" 对话框中的 "间隙轮廓" 设置来禁用间隙轮廓功能。

图标(从绘图工具栏或从顶部工具栏 布线 菜单中)或使用快捷键 X。 点击一个起始位置,选择要布线的网络,并开始布线。 布线的网络会自动高亮显示,网络允许的间隙会在当前布线的周围用灰色的轮廓表示。 可以通过改变 "偏好设置" 对话框中的 "间隙轮廓" 设置来禁用间隙轮廓功能。

| 间隙轮廓显示从布线网络到 PCB 上任何其他铜对象的最大间隙。 可以使用自定义设计规则为不同对象指定网络的不同间隙。 布线器将考虑这些间隙,但仅直观地显示最大间隙值。 |

当布线器处于活动状态时,将从布线起点到编辑器光标绘制新的线段。这些线段是未固定的临时 (unfixed temporary) 对象,它们显示当您左键鼠标或 Enter 键来确定布线 (fix the route) 时将创建哪些线段。非固定布线段以比固定布线段更亮的颜色显示。当您使用 Esc 键或通过选择另一个工具退出布线器时,将只保存固定布线段。完成布线操作(快捷键 End) 将固定所有布线并退出布线器。

在布线时,可以使用 "撤消上一个布线段" 命令 (快捷键 Backspace) 取消上一个固定的布线。您可以重复使用此命令后退已固定的布线。

In previous versions of KiCad, using the left mouse button or Enter to fix the routed segments would fix all segments up to but not including the segment ending at the mouse cursor location. In KiCad 6 and later, this behavior is optional, and by default, all segments including the one ending at the mouse cursor location will be fixed. The old behavior can be restored by disabling the "Fix all segments on click" option in the Interactive Router Settings dialog.

布线时,可以按住 Ctrl 键禁用网格捕捉,按住 Shift 键禁用对焊盘和过孔等对象的捕捉。

| 也可以通过更改偏好设置对话框的编辑选项部分中的磁吸点首选项来禁用对象的捕捉。 我们建议您在一般情况下保持启用对象捕捉,这样就不会意外地在焊盘或过孔上略微偏离中心结束布线。 |

交互式布线设置

The interactive router settings can be accessed through the Route menu, or by right-clicking on the ![]() button in the toolbar. These settings control the router behavior when routing tracks as well as when dragging existing tracks.

button in the toolbar. These settings control the router behavior when routing tracks as well as when dragging existing tracks.

| Setting | Description |

|---|---|

Mode |

Sets the operating mode of the router for creating new tracks and dragging existing tracks. See the routing overview for more information. |

Free angle mode |

Allows routing tracks at any angle, instead of just at 45-degree increments. This option is only available if the router mode is set to Highlight collisions. |

Allow DRC violations |

Allow placing tracks and vias that violate DRC rules. This option is only available if the router mode is set to Highlight collisions. |

Shove vias |

Allow the router to shove vias along with tracks. When this is disabled, vias cannot be shoved. This option is only available if the router mode is set to Shove. |

Jump over obstacles |

Allow the router to attempt to move colliding tracks behind solid obstacles (such as pads). This option is only available if the router mode is set to Shove. |

Remove redundant tracks |

Automatically removes loops created in the currently-routed track, keeping only the most recently routed section of the loop. |

Optimize pad connections |

When this setting is enabled, the router attempts to avoid acute angles and other undesirable routing when exiting pads and vias. |

Smooth dragged segments |

When dragging tracks, attempts to combine track segments together to minimize direction changes. |

Optimize entire track being dragged |

When enabled, dragging a track segment will result in KiCad optimizing the rest of the track that is visible on the screen. The optimization process removes unnecessary corners, avoids acute angles, and generally tries to find the shortest path for the track. When disabled, no optimizations are performed to the track outside of the immediate section being dragged. |

Use mouse path to set track posture |

Attempts to pick the track posture based on the mouse path from the routing start location. |

Fix all segments on click |

When enabled, clicking while routing will fix the position of all the track segments that have been routed, including the segment that ends at the mouse cursor. A new segment will be started from the mouse cursor location. When disabled, the last segment (the one that ends at the mouse cursor) will not be fixed in place and can be adjusted by further mouse movement. |

布线形态

在水平(H) / 垂直 (V) / 45 度模式下布线时,形态 是指一组两个线段如何连接单个 H/V/45 度线段无法到达的两个点。 在这种情况下,这些点将由一条水平或垂直线段和一条斜线段 (45度) 连接。形态指的是这些线段的顺序:是水平/垂直线段在前还是斜线段在前。

KiCad 的布线器会尝试根据一系列因素自动选择最佳形态。一般说来,布线器会尝试最大限度地减少路线中的拐角数量,并尽可能避免 "槽糕" 的拐角 (如锐角)。当从焊盘布线或布线到焊盘时,KiCad 将选择使路线与焊盘最长边缘对齐的形态。

在某些情况下,KiCad 无法正确猜测您想要的形态。要在布线时切换布线的形态,请使用切换布线形态命令 (快捷键 /)。

In situations where there is no obvious "best" posture (for example, when starting a route from a via), KiCad will use the movement of your mouse cursor to select the posture. If you would like the route to begin with a straight (horizontal or vertical) segment, move the mouse away from the starting location in a mostly horizontal or vertical direction. If you would like the route to begin diagonally, move in a diagonal direction. Once the cursor is a sufficient distance away from the routing start location, the posture is set and will no longer change unless the cursor is brought back to the starting location. Detection of posture from the movement of the mouse cursor can be disabled in the Interactive Router Settings dialog as described below.

| 如果使用切换布线形态(Switch Track Posture)命令覆盖 KiCad 选择的形态,则在当前布线操作的剩余部分中,将禁用鼠标移动姿势的自动检测。 |

布线转角模式

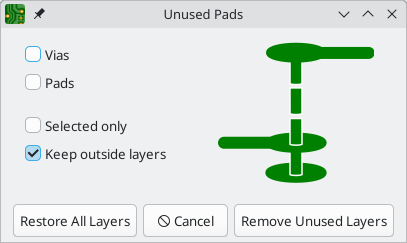

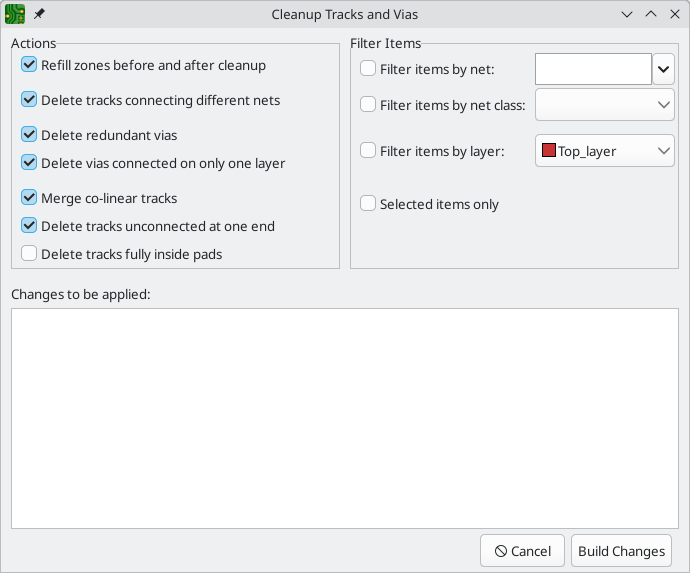

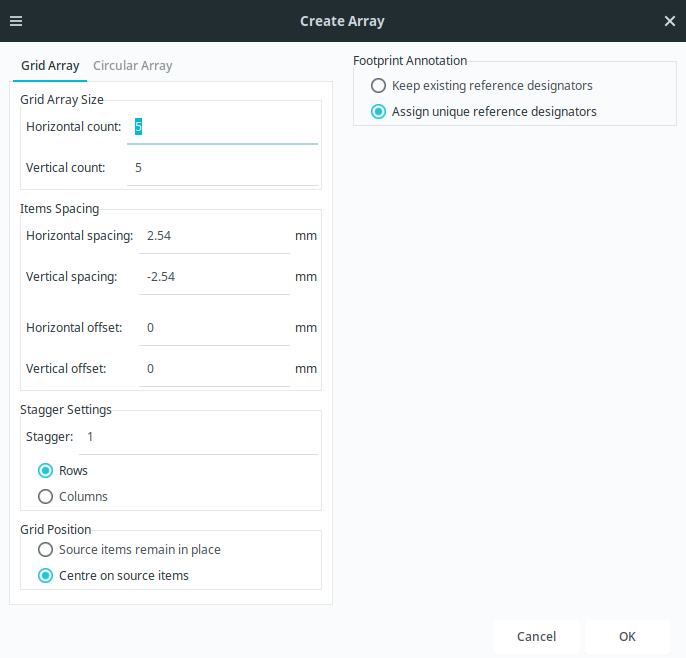

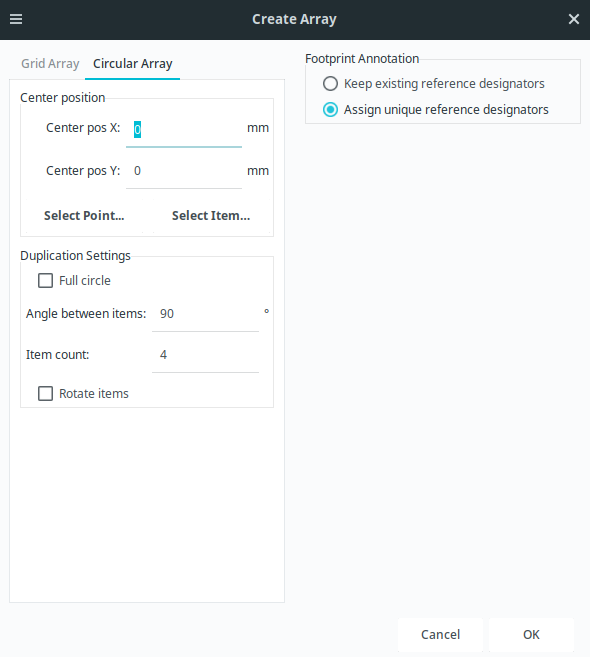

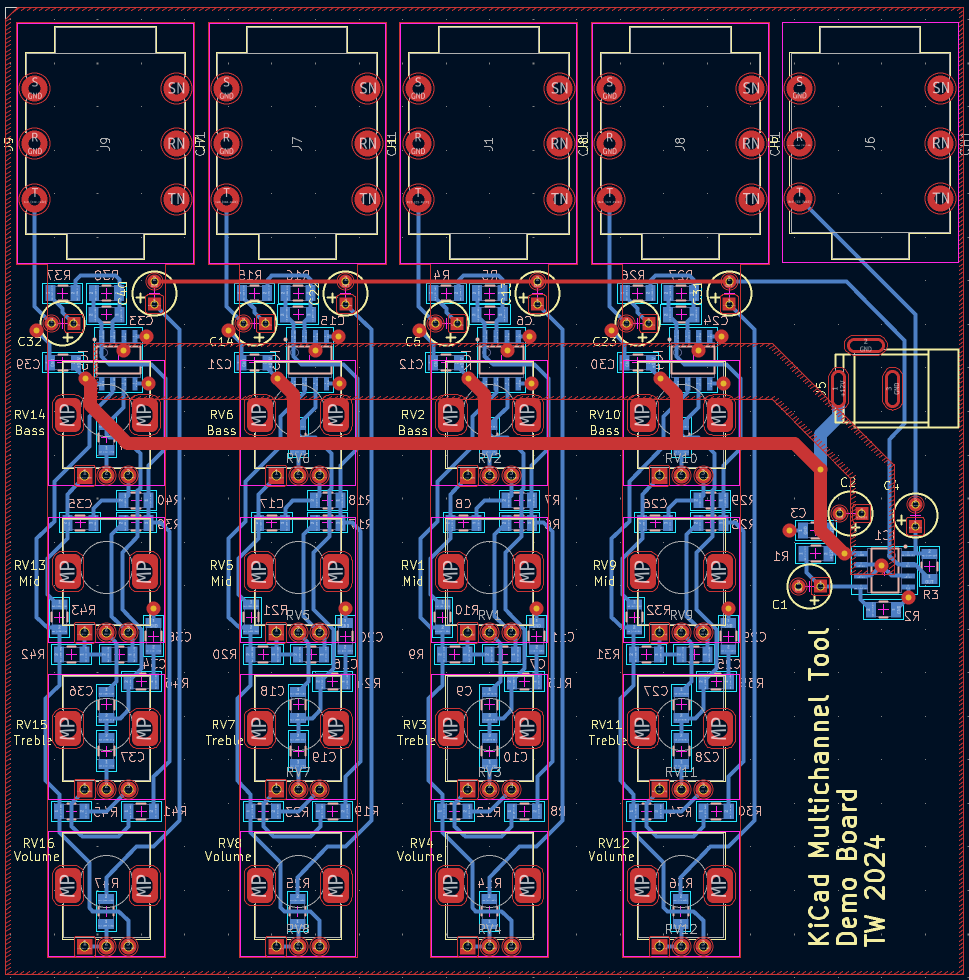

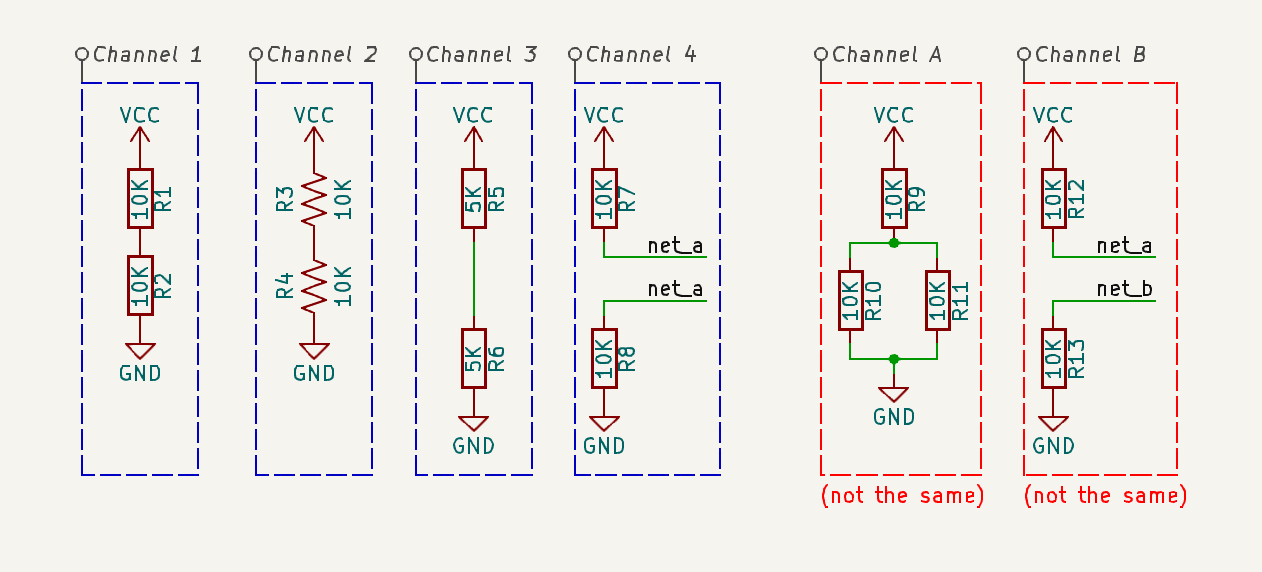

当以 H/V/45 模式布线时,KiCad 的布线器可以放置尖角或圆角 (弧形) 的布线。要在尖角和圆角之间切换,请使用布线拐角模式命令 (快捷键 Ctrl+/)。使用圆角布线时,每个布线步骤将放置直线段、单个圆弧或同时放置直线段和圆弧。布线形态决定首先放置圆弧还是直线段。