Reference manual

| This manual is in the process of being revised to cover the latest stable release version of KiCad. It contains some sections that have not yet been completed. We ask for your patience while our volunteer technical writers work on this task, and we welcome new contributors who would like to help make KiCad’s documentation better than ever. |

Copyright

This document is Copyright © 2010-2024 by its contributors as listed below. You may distribute it and/or modify it under the terms of either the GNU General Public License (http://www.gnu.org/licenses/gpl.html), version 3 or later, or the Creative Commons Attribution License (http://creativecommons.org/licenses/by/3.0/), version 3.0 or later.

All trademarks within this guide belong to their legitimate owners.

Contributors

Jean-Pierre Charras, Fabrizio Tappero, Wayne Stambaugh, Cirilo Bernardo, Jon Evans, Graham Keeth

Feedback

The KiCad project welcomes feedback, bug reports, and suggestions related to the software or its documentation. For more information on how to sumbit feedback or report an issue, please see the instructions at https://www.kicad.org/help/report-an-issue/

Introduction to the KiCad PCB Editor

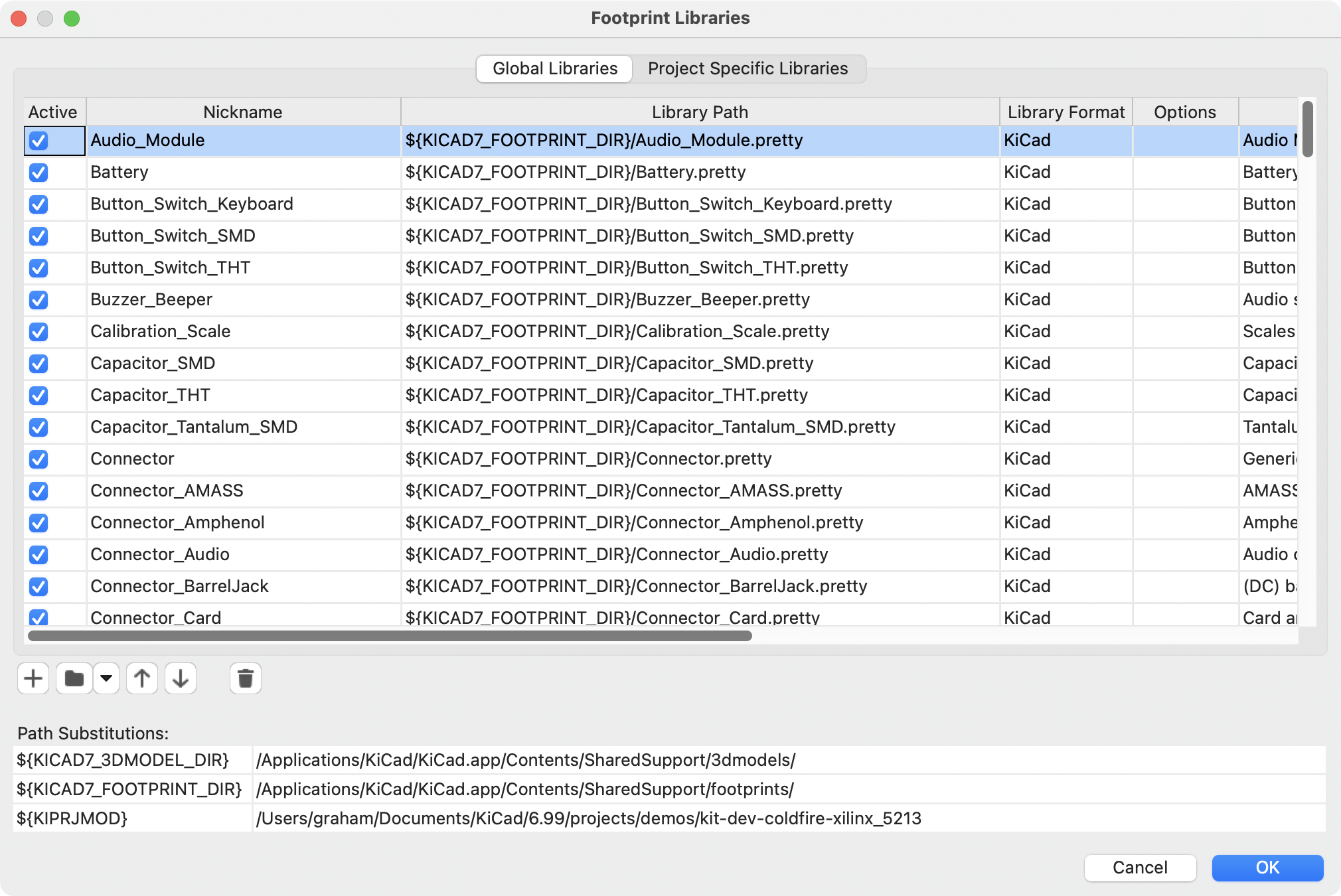

Initial configuration

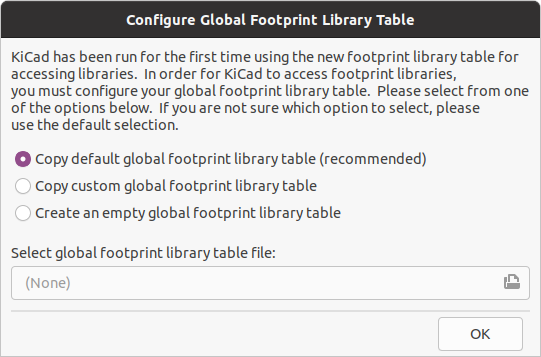

When the PCB Editor is run for the first time, if the global footprint table file fp-lib-table is not

found in the KiCad configuration folder then the KiCad will ask how to create this file:

The first option is recommended (Copy default global footprint library table (recommended)). The default footprint library table includes all of the standard footprint libraries that are installed as part of KiCad.

If this option is disabled, KiCad was unable to find the default global footprint library table. This probably means you did not install the standard footprint libraries with KiCad, or they are not installed where KiCad expects to find them. On some systems the KiCad libraries are installed as a separate package.

-

If you have installed the standard KiCad footprint libraries and want to use them, but the first option is disabled, select the second option and browse to the

fp-lib-tablefile in the directory where the KiCad libraries were installed. -

If you already have a custom footprint library table that you would like to use, select the second option and browse to your

fp-lib-tablefile. -

If you want to construct a new footprint library table from scratch, select the third option.

Footprint library management is described in more detail later.

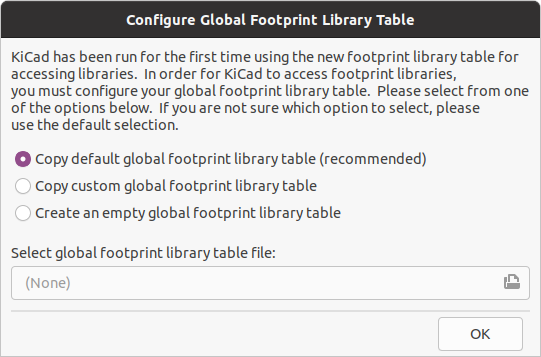

The PCB Editor user interface

The main PCB Editor user interface is shown above, with some key elements indicated:

-

Top toolbars (file management, zoom tools, editing tools)

-

Left toolbar (display options)

-

Message panel and status bar

-

Right toolbar (drawing and design tools)

-

Appearance panel

-

Selection filter panel

Navigating the editing canvas

The editing canvas is a view onto the board being designed. You can pan and zoom to different areas of the board, and also flip the view to show the board from the bottom.

By default, dragging with the middle or right mouse button will pan the canvas view and scrolling the mouse wheel will zoom the view in or out. You can change this behavior in the Mouse and Touchpad section of the preferences (see Configuration and Customization for details).

Several other zoom tools are available in the top toolbar:

-

zooms in on the center of the

viewport.

zooms in on the center of the

viewport. -

zooms out from the center of

the viewport.

zooms out from the center of

the viewport. -

zooms to fit the

frame around the drawing sheet.

zooms to fit the

frame around the drawing sheet. -

zooms to

fit the items within the drawing sheet.

zooms to

fit the items within the drawing sheet. -

allows you to

draw a box to determine the zoomed area.

allows you to

draw a box to determine the zoomed area.

The cursor’s current position is displayed at the bottom of the window (X and Y), along with the current zoom factor (Z), the cursor’s relative position (dx, dy, and dist), the grid setting, and the display units.

The relative coordinates can be reset to zero by pressing Space. This is useful for measuring distance between two points or aligning objects.

Hotkeys

The Ctrl+F1 shortcut displays the current hotkey list. The default hotkey list is included in the Actions Reference section of the manual.

The hotkeys described in this manual use the key labels that appear on a standard PC keyboard. On an Apple keyboard layout, use the Cmd key in place of Ctrl, and the Option key in place of Alt.

Many actions do not have hotkeys assigned by default, but hotkeys can be assigned or redefined using the hotkey editor (Preferences → Preferences… → Hotkeys).

| Many of the actions available through hotkeys are also available in context menus. To access the context menu, right-click in the editing canvas. Different actions will be available depending on what is selected or what tool is active. |

Hotkeys are stored in the file user.hotkeys in KiCad’s configuration

directory. The location is platform-specific:

-

Windows:

%APPDATA%\kicad\7.0\user.hotkeys -

Linux:

~/.config/kicad/7.0/user.hotkeys -

macOS:

~/Library/Preferences/kicad/7.0/user.hotkeys

KiCad can import hotkey settings from a user.hotkeys file using the Import

Hotkeys button in the hotkey editor.

Display and selection controls

Board layers

Layers in the PCB Editor represent physical copper layers on a board, as well as graphical layers used for defining things such as silkscreen, solder mask, and the board edge. There is always one layer that is active in the editor. The active layer is drawn on top of other layers and will be the layer assigned to newly-created objects. The active layer is indicated in the layer selector drop-down box in the top toolbar and is also highlighted in the appearance panel. To change the active layer, you can left-click a layer name in the appearance panel, use the drop-down layer selector in the top toolbar, or use a hotkey. Layers can be hidden to simplify the board view. You can hide a layer even if it is the active layer.

Display order for board layers

| TODO: Explain this. |

The appearance panel

The appearance panel provides controls to manage the visibility, color, and opacity of objects in the PCB Editor’s drawing canvas. It has three tabs: the Layers tab contains controls for the board layers, the Objects tab contains controls for different types of graphical objects, and the Nets tab contains controls for the appearance of the ratsnest and copper items.

Layer controls

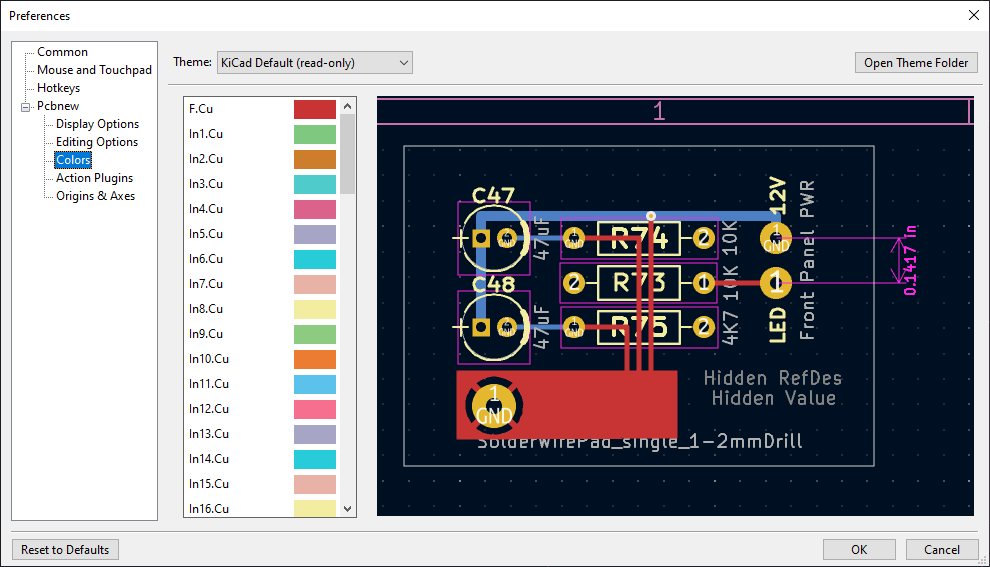

In the Layers tab of the appearance panel, each board layer is shown with its color and visibility state. The active layer is shown highlighted with an arrow indicator to the left of the color swatch. Left-click on a layer to choose it as the active layer. Left-click on the corresponding visibility icon to toggle the layer between visible and hidden. Double-click or middle-click on the color swatch to change the layer’s color.

| You must first create a custom color theme in Preferences before you can change layer colors in the appearance panel. |

Below the list of layers is an expandable panel that contains layer display options. The first setting controls how non-active layers are displayed: normal, dimmed, or hidden. The layer display mode can be used to simplify the view and focus on a single layer. Items on inactive layers cannot be selected when the non-active layer display mode is "Dim" or "Hide". You can use the hotkey Ctrl+H to cycle through these display modes quickly.

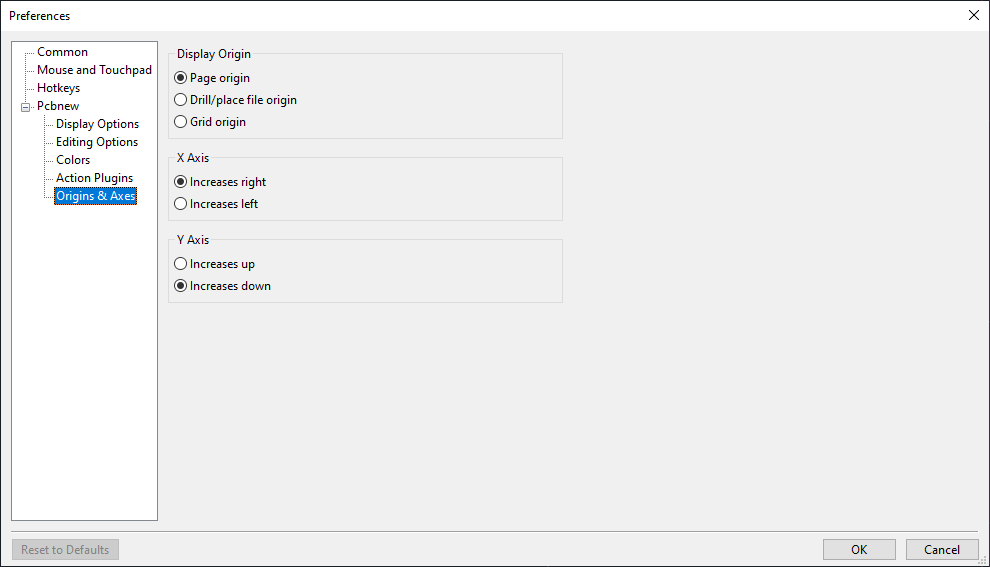

Flip board view will show the board as if you are looking from the bottom (that is, mirrored around the Y-axis). This option is also available in the View menu.

| Flipping the board view does not change the visual layer ordering, the active layer will remain in front followed by the other layers in their normal order. |

Object controls

The Objects tab of the appearance panel is similar to the Layers tab. The main differences are that some objects have no color setting and that four types of objects (tracks, vias, pads, and zones) have opacity control sliders. The opacity setting here will be multiplied with any opacity set in the layer colors. By default, all objects are fully opaque except for zones, which are set to translucent in order to make it easier to see objects through filled zone areas.

Layer presets

Layer presets store which layers and objects are visible and hidden for easy recall. There are several built-in layer presets and you can save your own custom presets. Custom presets are stored in the project settings for a board, as presets may be specific to a certain board stackup.

To load a preset, choose it from the Presets drop-down menu at the bottom of the appearance panel or use the quick switcher by holding down Ctrl and pressing Tab. Once the quick switcher window appears, you can press Tab and Shift+Tab to cycle through the available presets. When you let go of the Ctrl key, the highlighted preset will be loaded.

To save a custom preset, first use the visibility controls to choose which layers you want visible, then choose Save Preset… from the Presets drop-down menu. Give your preset a name and it will now be available via the drop-down menu and the quick switcher. To modify a custom preset, follow the same process and save the modified version with the same name to overwrite the existing version. To delete a custom preset, choose the Delete Preset… option from the drop-down menu and select the preset to be deleted from the list.

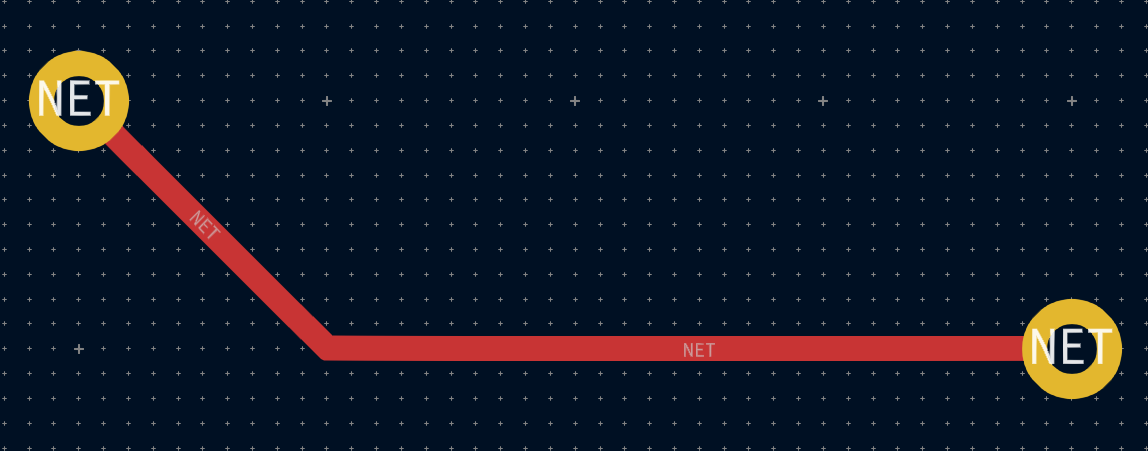

Net and net class controls

The Nets tab of the appearance panel shows a list of all nets and net classes in the board. Each net has a visibility control that controls the visibility of that net in the ratsnest. Hiding nets in the ratsnest does not change the connectivity of the board and will not impact the design rule checker; it only is intended to make the ratsnest easier to understand.

Each net and net class can also have a color assigned. By default, this color applies to the ratsnest lines for the net (or for all the nets in the net class). Nets have no color by default; this is indicated by a checkerboard pattern in the color swatch. Double-click or right-click a net or net class color swatch to set the color.

| The Default net class cannot have a color assigned, as nets in this class will just use the default ratsnest color defined by the color theme. |

You can also select and highlight nets and net classes via the appearance panel: right-click on a net or net class to show these options in a menu.

Below the list of net classes is an expandable panel that contains net display options. The first option controls how net colors are applied. When "All" is selected, all copper items (pads, tracks, vias, and zones) belonging to a net or net class will take on the chosen color. When "Ratsnest" is selected (the default value), only the ratsnest is affected by net and net class colors. When "None" is selected, net and net class colors are ignored.

The second option controls how ratsnest lines are drawn. "All layers" means that ratsnest lines will be drawn between all unconnected items. "Visible layers" means that no ratsnest lines will be drawn to items that are on hidden layers, even when those items are unconnected.

Selection and the selection filter

Selecting items in the editing canvas is done with the left mouse button. Single-clicking on an object will select it and dragging will perform a box selection. A box selection from left to right will only select items that are fully inside the box. A box selection from right to left will select any items that touch the box. A left-to-right selection box is drawn in yellow, with a cursor that indicates exclusive selection, and a right-to-left selection box is drawn in blue with a cursor that indicates inclusive selection.

The selection action can be modified by holding modifier keys while clicking or dragging. The following modifier keys apply when clicking to select single items:

| Modifier Keys (Windows) | Modifier Keys (Linux) | Modifier Keys (macOS) | Selection Effect |

|---|---|---|---|

Ctrl |

Ctrl |

Cmd |

Toggle selection. Note: Ctrl+click can be remapped to highlight net in Preferences → PCB Editor → Editing Options. |

Shift |

Shift |

Shift |

Add the item to the existing selection. |

Ctrl+Shift |

Ctrl+Shift |

Cmd+Shift |

Remove the item from the existing selection. |

long click |

long click or Alt |

long click or Option |

Clarify selection from a pop-up menu. |

The following modifier keys apply when dragging to perform a box selection:

| Modifier Keys (Windows) | Modifier Keys (Linux) | Modifier Keys (macOS) | Selection Effect |

|---|---|---|---|

Ctrl |

Ctrl |

Cmd |

Toggle selection. |

Shift |

Shift |

Shift |

Add item(s) to the existing selection. |

Ctrl+Shift |

Ctrl+Shift |

Cmd+Shift |

Remove item(s) from the existing selection. |

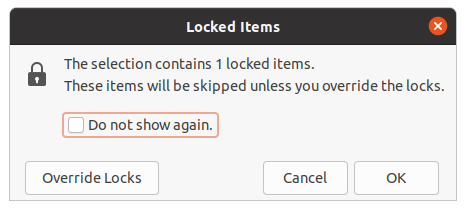

The selection filter panel in the lower right corner of the PCB Editor window controls which types of objects can be selected with the mouse. Turning off selection of unwanted object types makes it easier to select items in a dense board. The "All items" checkbox is a shortcut to turn the other items on and off. The "Locked items" checkbox is independent of the rest, and controls whether or not items that have been locked can be selected. You can right-click any object type in the selection filter to quickly change the filter to only allow selecting that type of object.

When a connected copper item is selected, you can expand the selection to other copper items of the same net using the Expand Selection command in the right-click context menu or with the hotkey U. The first time you run this command, the selection will be expanded to the nearest pad. The second time, the selection will be expanded to all connected items on all layers.

Selecting an object displays information about the object in the message panel at the bottom of the window. Double-clicking an object opens a window to edit the object’s properties.

Pressing Esc will always cancel the current tool or operation and return to the selection tool. Pressing Esc while the selection tool is active will clear the current selection.

Net highlighting

An electrical net (or set of nets) can be highlighted in the PCB editor to visualize how the net is routed across the PCB. Net highlighting can be activated by selecting the net to highlight in the PCB editor or by selecting the corresponding net in the schematic editor when cross-probe highlighting is enabled (see below). When net highlighting is active, the highlighted net or nets will be shown in a brighter color and all other items will be shown in a dimmer color than normal.

There are three ways to select a net or nets to highlight in the PCB editor: by using the hotkey ` after selecting a copper object, by using the context menu of any copper object, and the context menu of the Nets tab of the Appearance panel. When you press the Highlight Net hotkey, the nets of any selected copper items will be highlighted. If no copper items are selected, the net of the copper item under the editor cursor will be highlighted.

Net highlighting can be cleared by using the Clear Net Highlight action (hotkey ~) or by using the Highlight net tool on an empty region in the schematic. By default, Esc also clears net highlighting, but this can be disabled if desired in Preferences → PCB Editor → Editing Options.

When a net or nets have been selected for highlighting, the Toggle Net Highlighting action becomes enabled on the left toolbar (also accessible by hotkey, Ctrl+`). This action will turn the highlighting display on or off without choosing a new net to highlight.

Cross-probing from the schematic

KiCad allows bi-directional cross-probing between the schematic and the PCB. There are several different types of cross-probing.

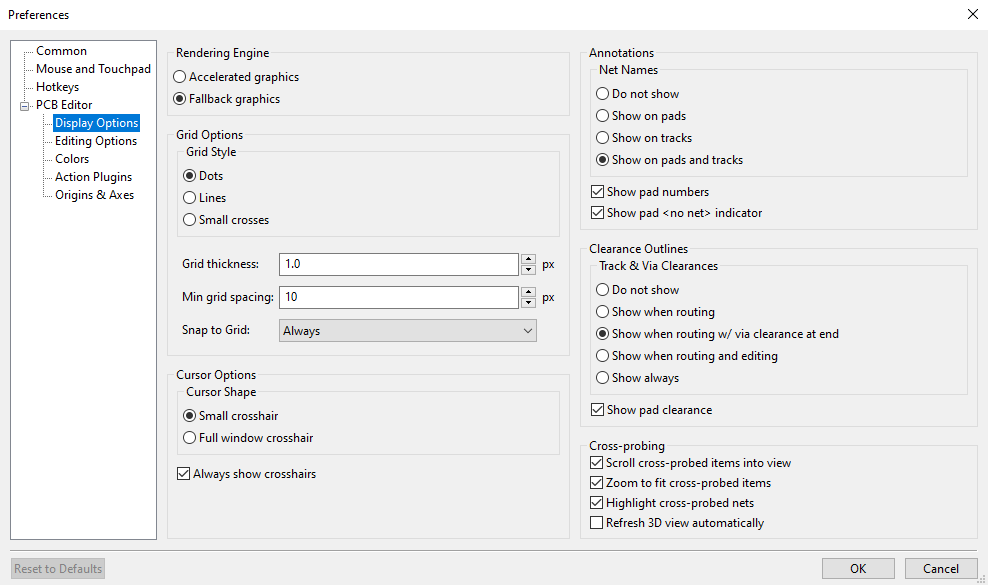

Selection cross-probing allows you to select a symbol or pin in the schematic to select the corresponding footprint or pad in the PCB (if one exists) and vice-versa. By default, cross-probing will result in the display centering on the cross-probed item and zooming to fit. This behavior can be disabled in the Display Options section of the Preferences dialog.

Highlight cross-probing allows you to highlight a net in the schematic and PCB at the same time. If the option "Highlight cross-probed nets" is enabled in the Display Options section of the Preferences dialog, highlighting a net or bus in the schematic editor will cause the corresponding net or nets to be highlighted in the PCB editor.

Left toolbar display controls

The left toolbar provides options to change the display of items in the PCB Editor.

|

Turns grid display on/off. Note: by default, hiding the grid will disable grid snapping. This behavior can be changed in the Display Options section of Preferences. |

|

Switch between polar and Cartesian coordinate display in the status bar. |

|

Display/entry of coordinates and dimensions in inches, mils, or millimeters. |

|

Switches between full-screen and small editing cursor (crosshairs). |

|

Turns the ratsnest display on/off. |

|

Switches between straight and curved ratsnest lines. |

|

Switches the non-active layer display mode between Normal and Dim. Note: this button will be highlighted when the non-active layer display mode is either Dim or Hide. In both cases, pressing the button will change the layer display mode to Normal. The Hide mode can only be accessed via the controls in the Appearance Panel or via the hotkey Ctrl+H. |

|

When a net has been selected for highlighting, switches the highlighting on or off. Note: this button will be disabled when no net has been highlighted. To highlight a net, use the hotkey `, right-click any copper object in the net and choose Highlight Net from the Net Tools menu, or right-click the net in the list in the Nets tab of the Appearance panel. |

|

Show zone filled areas. |

|

Show zone outlines only. |

|

Switches display of pads between filled and outline mode. |

|

Switches display of vias between filled and outline mode. |

|

Switches display of tracks between filled and outline mode. |

|

Shows or hides the Appearance and Selection Filter panels on the right side of the editor. |

|

Shows or hides the Properties Manager panel on the left side of the editor. |

Creating a PCB

Basic PCB concepts

A printed circuit board in KiCad is generally made up of footprints representing electronic components and their pads, nets defining how those pads connect to each other, tracks, vias, and filled zones that form the copper connections between pads in each net, and various graphic shapes defining the board edge, silkscreen markings, and any other desired information.

KiCad normally keeps the information about nets on a PCB synchronized with an associated schematic, but nets can also be created and edited directly within the PCB editor.

Capabilities

KiCad is capable of creating printed circuit boards with up to 32 copper layers, 14 technical layers (silkscreen, solder mask, component adhesive, solder paste, etc), and 13 general-purpose drawing layers.

The internal measurement resolution of all objects in KiCad is 1 nanometer, and measurements are stored as 32-bit integers. This means it is possible to create boards up to approximately 4 meters by 4 meters.

KiCad currently supports one board file per project / schematic.

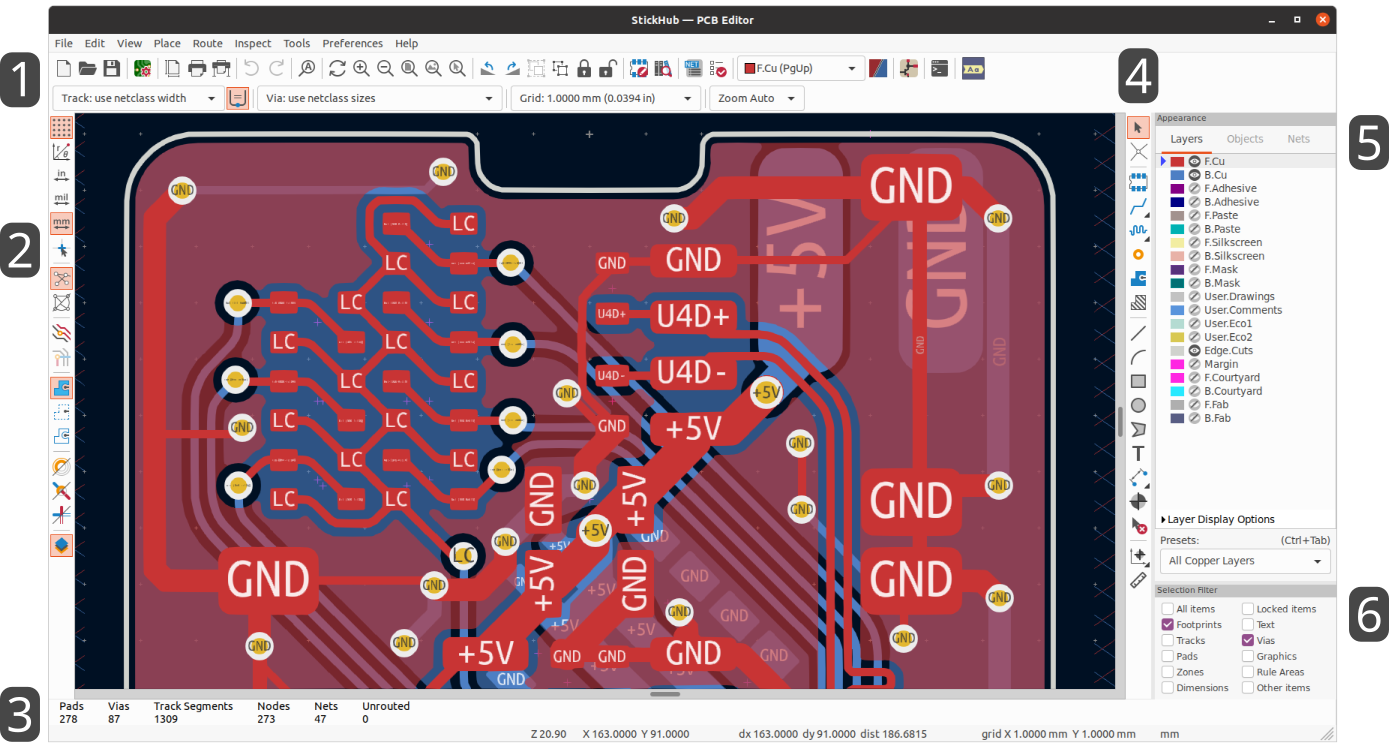

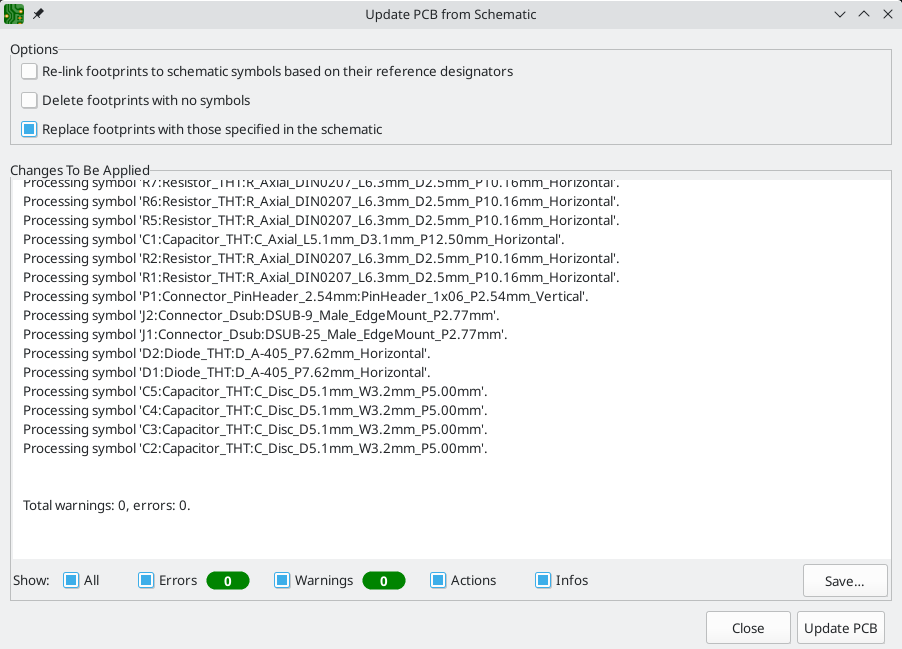

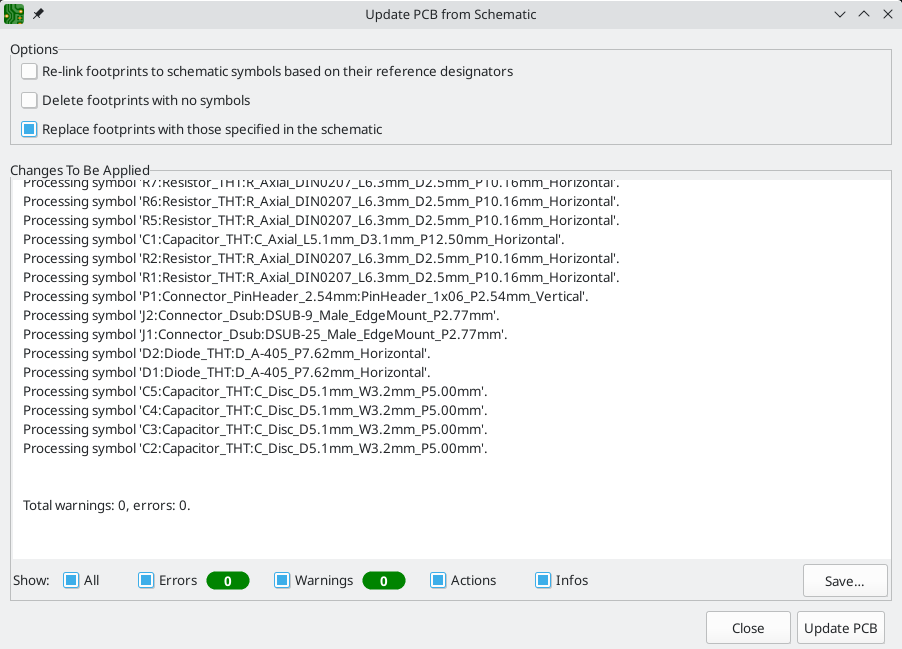

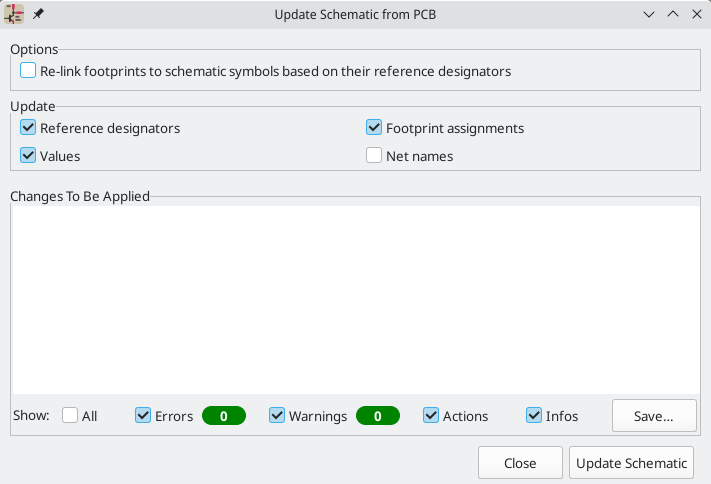

Starting from a schematic

Creating a board from a schematic is the recommended workflow for KiCad. When you create a new

project, KiCad will generate an empty board file with the same name as the project. To start

designing the board after you have created a schematic, simply open the board file. You can do

this either from the KiCad project manager, or by clicking the "Open PCB in board editor" button in

the schematic editor. To import the schematic design information into the board editor, including

footprints and net connections, use the Tools → Update Schematic from PCB… action

(F8). You can also use the

![]() icon in the top toolbar.

icon in the top toolbar.

| Update PCB from Schematic is the preferred way to transfer design information from the schematic to the PCB. In older versions of KiCad, the equivalent process was to export a netlist from the Schematic Editor and import it into the Board Editor. It is no longer necessary to use a netlist file. |

For more information about the Update Schematic from PCB tool, see the forward annotation section of the manual.

Starting from scratch

It is also possible to create a board with no matching schematic, although this workflow has some limitations and is not recommended for most users. To do this, you must start the PCB editor standalone (not from the KiCad project manager). Before beginning your design, it is a good idea to save the board file, which will also create a project file to store board settings. Use "Save As…" from the File menu to choose where to save your board file. A project file with the same name will be created in the same location you choose to save the board file in.

Board setup

Before beginning your board design, use the Board Setup dialog to configure the basic parameters of

the board. To open Board Setup, click the ![]() icon in the top

toolbar or choose "Board Setup…" from the File menu.

icon in the top

toolbar or choose "Board Setup…" from the File menu.

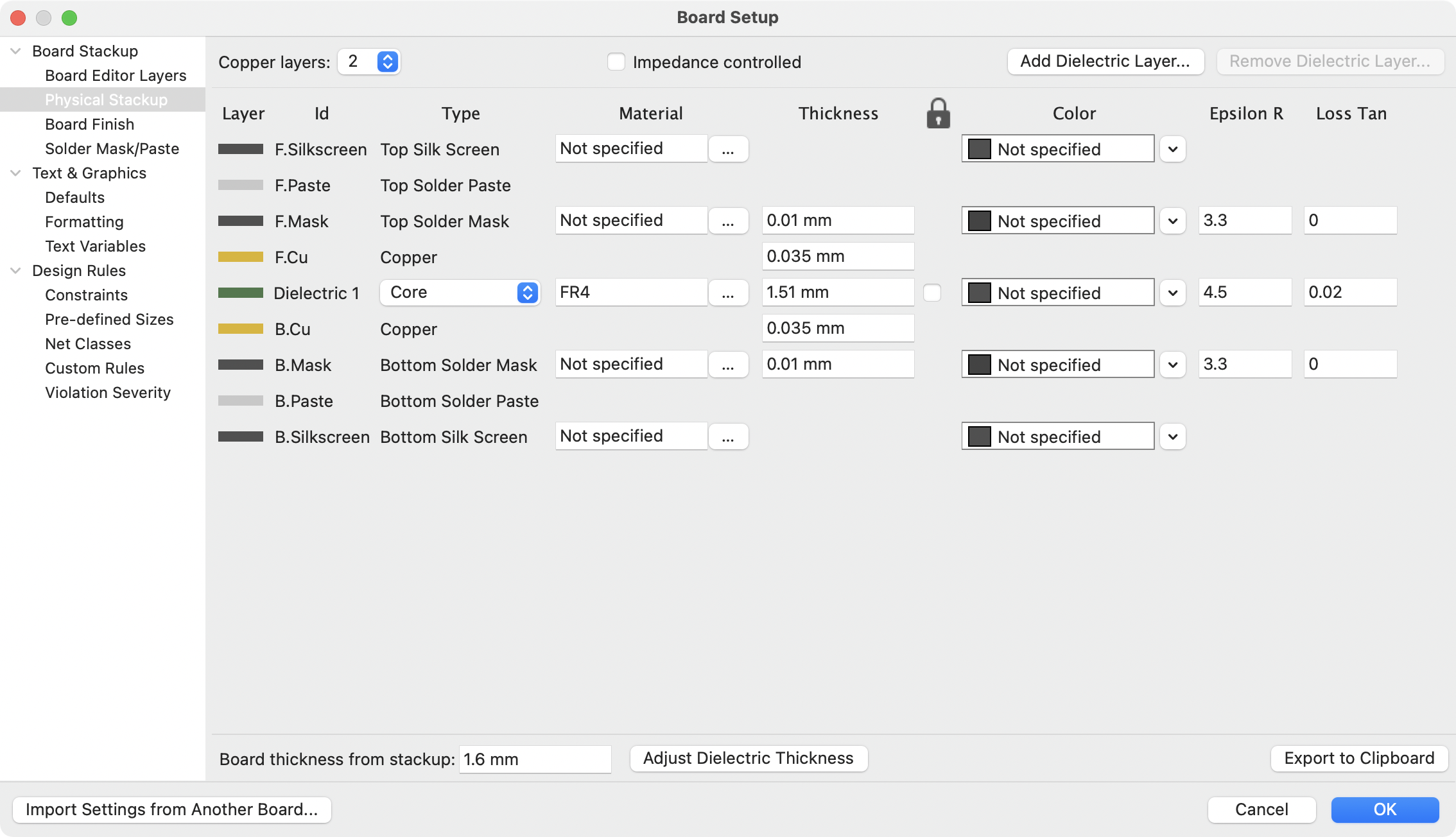

Configuring board stackup and physical parameters

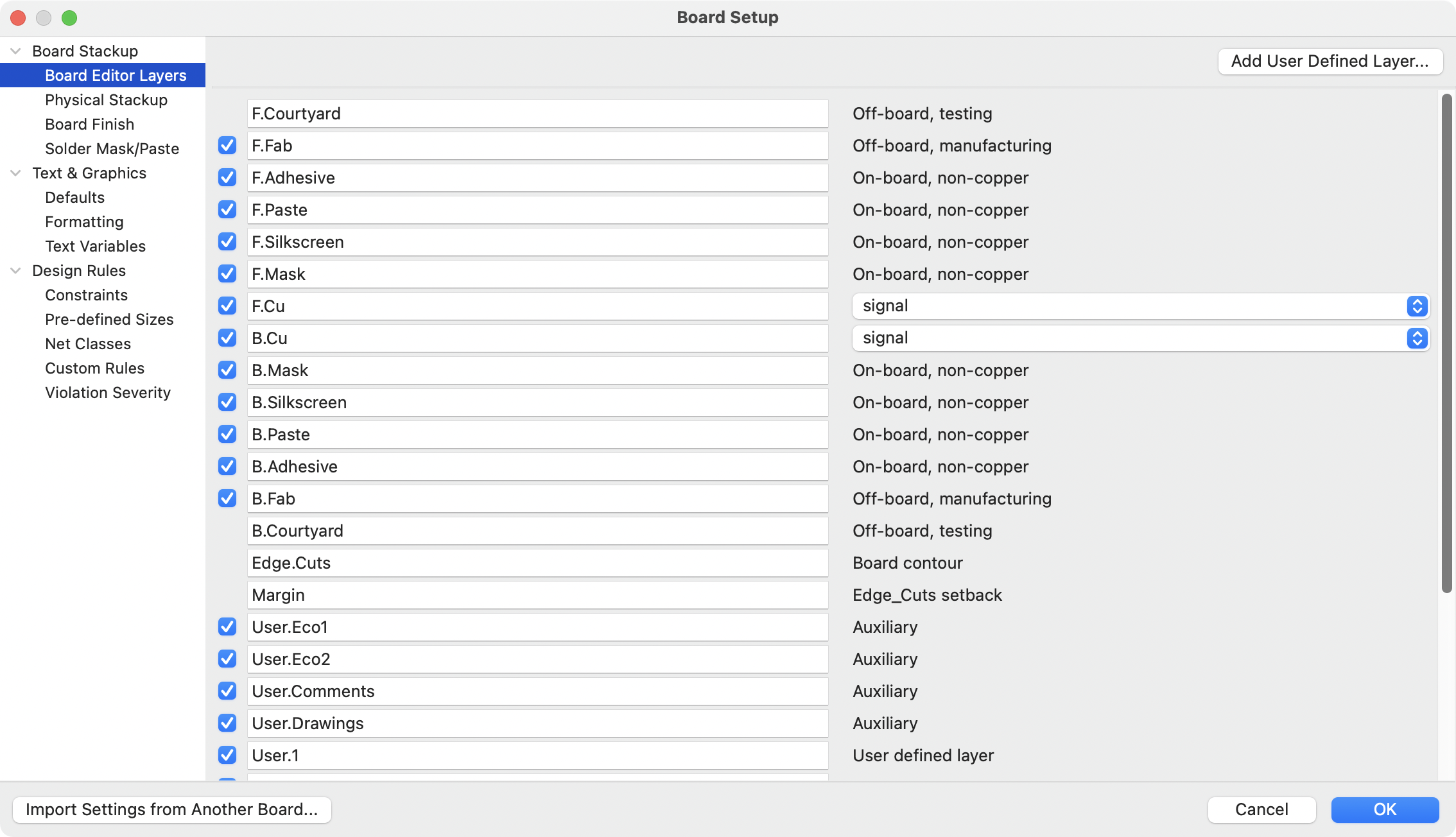

There are two sections of Board Setup used to configure the stackup and layers of the board. The Board Editor Layers section is used to enable or disable technical (non-copper) layers, and give custom names to layers if desired. The Physical Stackup section is used to configure the number of copper layers, as well as the physical parameters of the copper and dielectric layers such as thickness and material type. Dielectric, soldermask, and silkscreen layers can have colors assigned to them, which affects the board’s appearance in the 3D viewer.

To configure the board stackup, start on the Physical Stackup section:

Set the number of copper layers in the upper left corner and then enter the physical parameters of the stackup if desired. These parameters may be left at their default values, but note that the board thickness value will be used when exporting a 3D model of the board. If you plan to use this feature, it is a good idea to ensure that the stackup thickness is correct.

| KiCad currently only supports stackups with an even number of copper layers. To create designs with an odd number of layers (for example, flexible printed circuits or metal-core printed circuits), simply choose the next highest even number and ignore the extra layer. |

Next, if desired, use the Board Editor Layers section to rename layers or hide non-copper layers

that you will not be using in the design. For example, if you will not use a back silkscreen on

the design, uncheck the box next to the B.Silkscreen layer.

| Copper layers can be designated as signal, power plane, mixed, or jumper in the Board Editor Layers section. This designation is intended as a guide for the user only. Tracks and zones can be routed on any copper layer, no matter what the type is configured to in this dialog. |

Some additional board stackup settings are found on the Board Finish and Solder Mask/Paste sections of the Board Setup dialog. The Board Finish section has settings for defining the copper finish and special features such as castellations or edge plating. Note that these settings only impact the board attributes output as part of Gerber job files at this time.

The Solder Mask/Paste section allow global adjustment of the clearance (positive or negative) between the copper shapes and solder mask / solder paste shapes of pads on the board. These values will be added to any clearance overrides set on individual footprints or pads. Positive clearance values will result in the shape of the solder mask or paste opening being larger than the copper shape. Negative clearance values will result in the opening being smaller than the copper shape.

| Most commercial PCB fabricators expect these values to be zero and make their own adjustments to solder mask and paste openings as part of their CAM process. It is usually best to leave these values at their default of zero unless you are making the PCB yourself or have specific advice from your fabricator to use different values. |

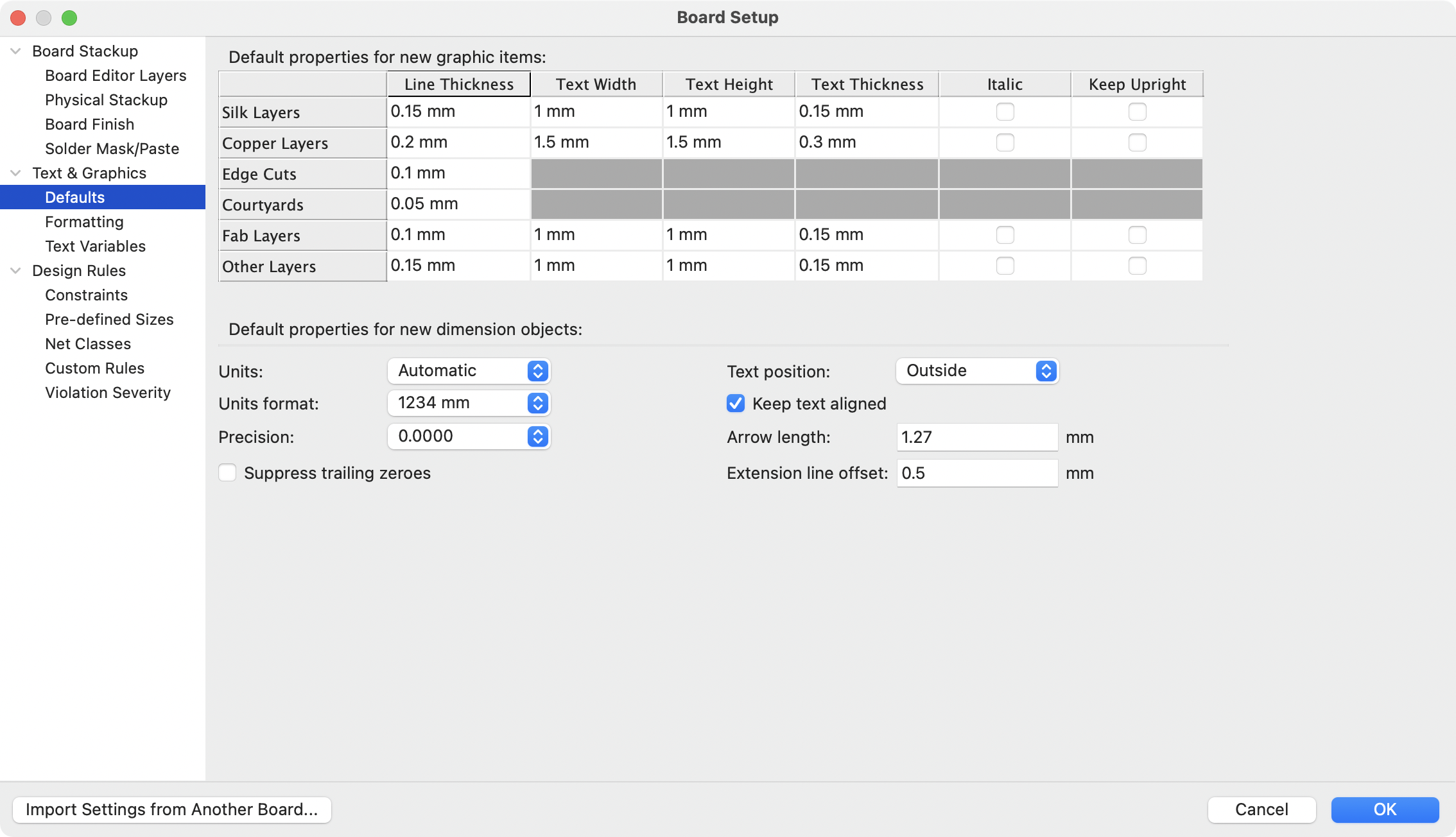

Configuring default text and graphic settings

The Text & Graphics Defaults section of the Board Setup dialog can be used to configure the properties that will be used for new text and graphic shapes that are placed on the board.

Line thickness, text size, and text appearance can be configured for the six different categories of layers shown in the dialog. Additionally, the properties for dimension objects can be configured for all layers. For more details about dimension properties, see the Dimensions section below.

Dashed line appearance is controlled in the Formatting section. Dash length

controls the length of dashes, while Gap length controls the spacing between

dashes and dots. The dash and gap lengths are relative to the line width: a gap

length of 2 means twice the width of the line.

Text replacement variables can be created in the Text Variables section. These variables allow

you to substitute the variable name for any text string. This substitution happens anywhere the

variable name is used inside the variable replacement syntax of ${VARIABLENAME}.

For example, you could create a variable named VERSION and set the text substitution to 1.0.

Now, in any text object on the PCB, you can enter ${VERSION} and KiCad will substitute 1.0. If

you change the substitution to 2.0, every text object that includes ${VERSION} will be updated

automatically. You can also mix regular text and variables. For example, you can create a text

object with the text Version: ${VERSION} which will be substituted as Version: 1.0.

Text variables can also be created in Schematic Setup. Text variables are project-wide; variables created in the schematic editor are also available in the board editor, and vice versa.

There are also a number of built-in system text variables.

Configuring design rules

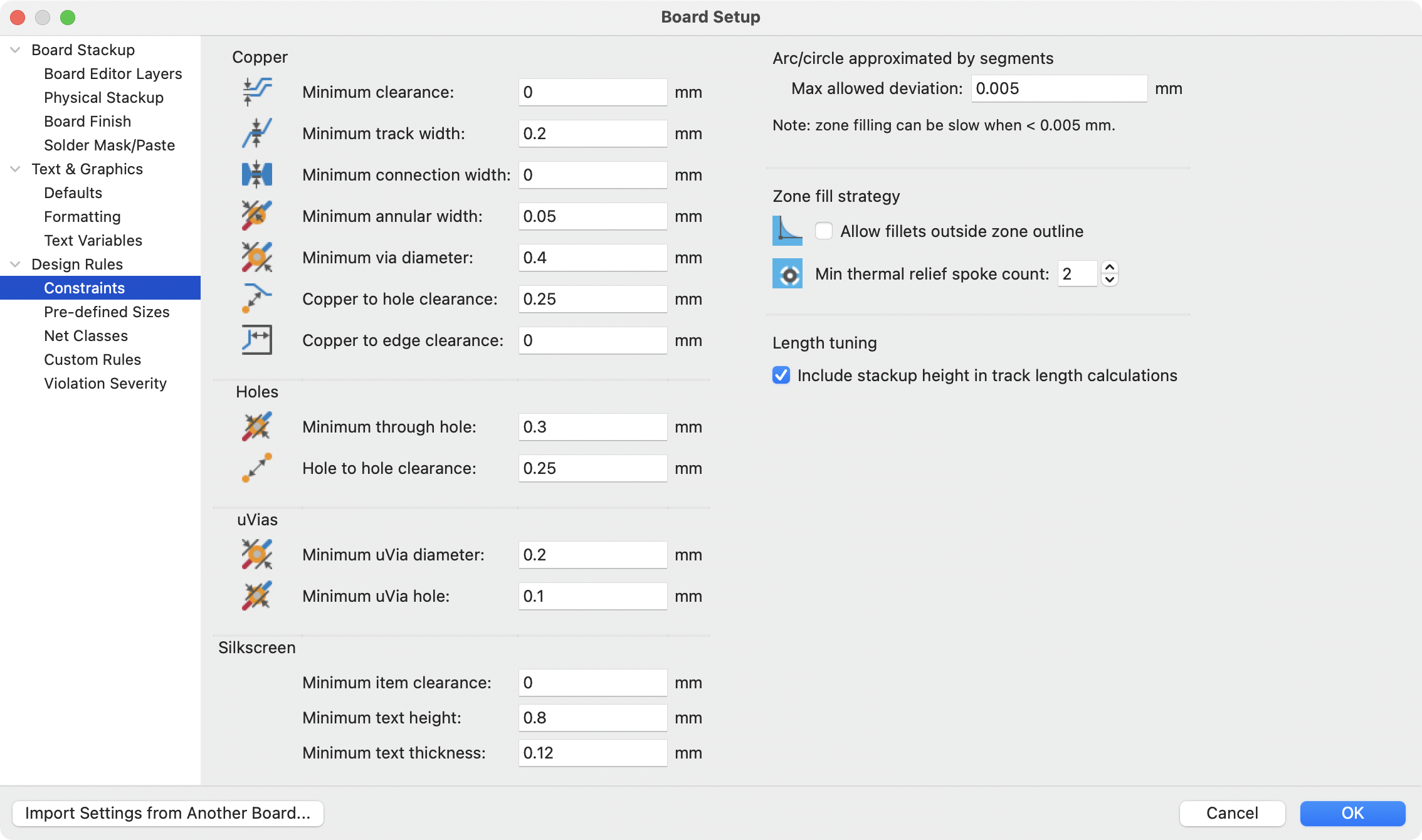

Design rules control the behavior of the interactive router, the filling of copper zones, and the design rule checker. Design rules can be modified at any time, but we recommend that you establish all known design rules at the beginning of the board design process.

Constraints

Basic design rules are configured in the Constraints section of the Board Setup dialog. Constraints in this section apply to the entire board and should be set to the values recommended by your board manufacturer. Any minimum value set here is an absolute minimum and cannot be overridden with a more specific design rule. For example, if you need the copper clearance on part of a board to be 0.2mm and in the rest 0.3mm, you must enter 0.2mm for the minimum copper clearance in the Constraints section and use a netclass or custom rule to set the larger 0.3mm clearance.

In addition to setting minimum clearances, a number of features can be configured here:

| Setting | Description |

|---|---|

Arc/circle approximated by segments |

In some situations, KiCad must use a series of straight line segments to approximate round shapes such as those of arcs and circles. This setting controls the maximum error allowed by this approximation: in other words, the maximum distance between a point on one of these line segments and the true shape of the arc or circle. Setting this to a lower number than the default value of 0.005mm will result in smoother shapes, but can be very slow on larger boards. The default value typically results in arc approximation error that is not detectable in the manufactured board due to manufacturing tolerances. |

Allow fillets outside zone outline |

Zones can have fillets (rounded corners) added in the Zone Properties dialog. By default, no zone copper, including fillets, is allowed outside the zone outline. This effectively means that inside corners of the zone outline will not be filleted even when a fillet is configured. By enabling this setting, inside corners of the zone outline will be filleted even though this results in copper from the zone extending outside the zone outline. |

Min thermal relief spoke count |

This sets the minimum acceptable number of thermal relief spokes connecting a pad to a zone. A DRC violation will be generated if this constraint is violated. |

Include stackup height in track length calculations |

By default, the height of the stackup is used to calculate the additional length of a track that travels through vias from one layer to another. This calculation relies on the board stackup height being correctly configured. In some situations, it is preferable to ignore the height of vias and just calculate the track length assuming that vias add no length. Disabling this setting will exclude via length from track length calculations. |

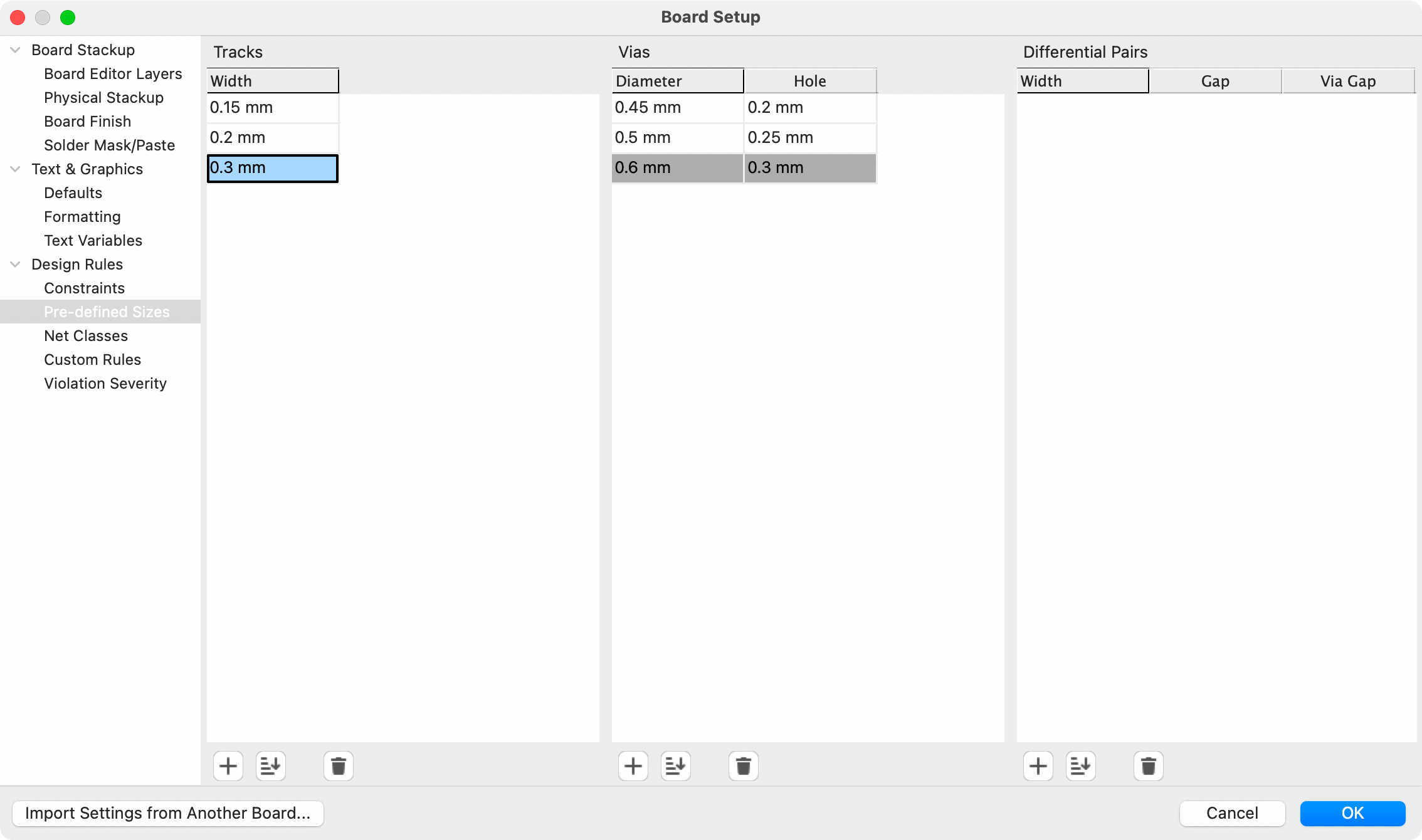

Pre-defined Sizes

The pre-defined sizes section allows you to define the track and via dimensions you want to have available while routing tracks. Net classes can be used to define the default dimensions for tracks and vias in different nets (see below) but defining a list of sizes in this section will allow you to step through these sizes while routing. For example, you may want the default track width on a board to be 0.2 mm, but use 0.3 mm for some sections that carry more current, and 0.15 mm for some sections where space is limited. You can define each of these track widths in the Board Setup dialog and then switch between them when routing traces.

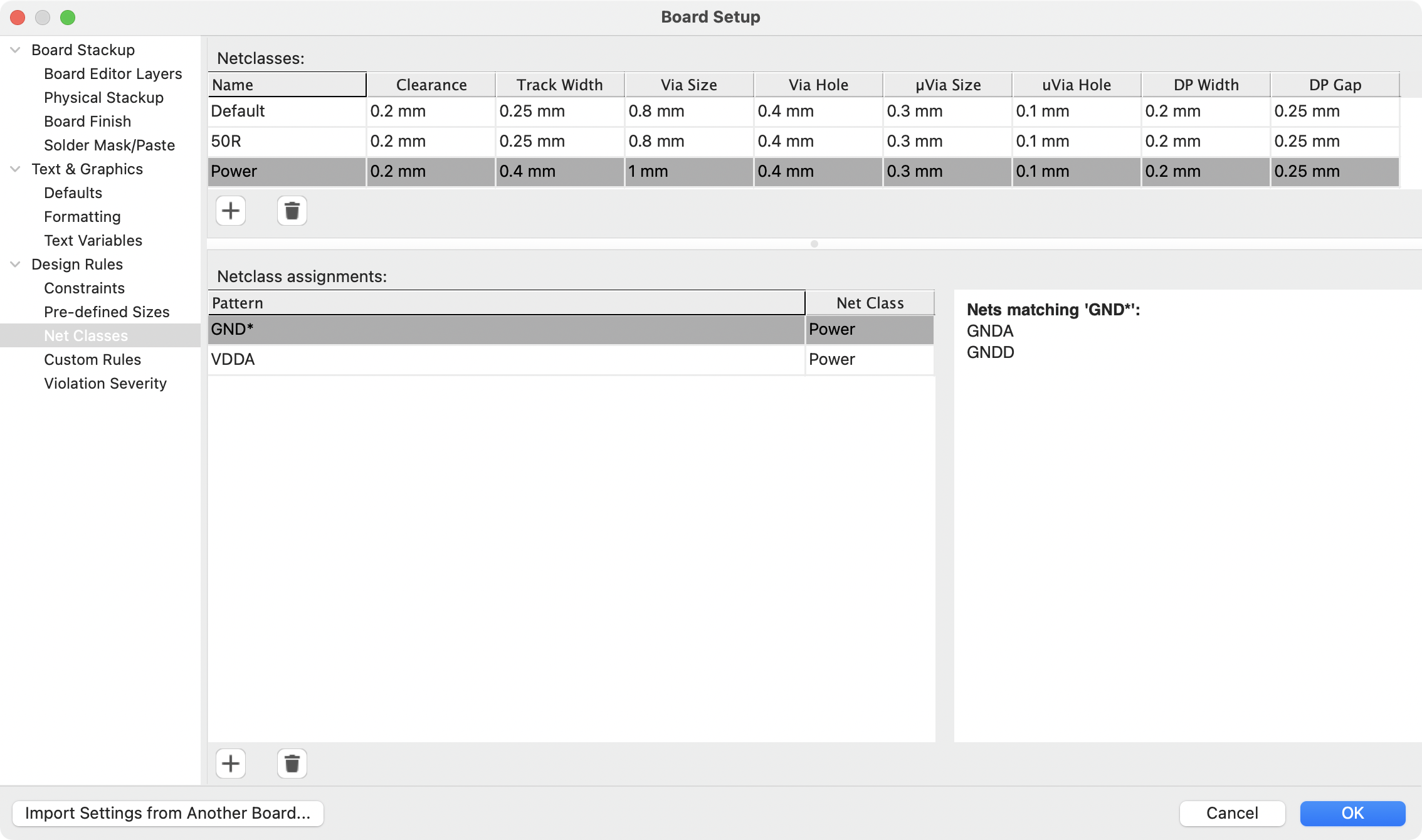

Net Classes

The Net Classes section allows you to configure routing and clearance rules for different classes of nets. In KiCad, each net is part of exactly one net class. If you do not add a net to a specific class, it will be part of the Default class, which always exists. Net classes may be created and edited in either the Schematic or Board Setup dialogs.

The upper portion of the Net Classes section contains a table showing the net classes in the design and the design rules that apply to each net class. Every class has values for copper clearance, track width, via sizes, and differential pair sizes. These values will be used when creating tracks and vias unless a more specific rule overrides them (see Custom Rules below).

No rule may override the minimum values set in the Constraints section of Board Setup. For

example, if you set a net class clearance to 0.1 mm, but the Minimum Clearance in the

Constraints section is set to 0.2 mm, nets in that class will have a clearance of 0.2 mm.

|

The track widths and via sizes defined for each net class are used when the track width and via size controls are set to "use netclass values" in the PCB editor. These widths and sizes are considered the default, or optimal, sizes for that netclass. They are not minimum or maximum values. Manually changing the track width or via size to a different value from that defined in the Net Classes section will not result in a DRC violation. To restrict track width or via size to specific values, use Custom Rules.

The lower portion of the Net Classes section lists pattern-based netclass assignments. Working with pattern-based netclass assignments is explained in the Schematic Editor documentation; pattern-based assignments can be edited in either the Board or Schematic Setup windows.

Note that pattern-based assignments can be created directly from the PCB editing canvas by right clicking a copper track or zone and clicking Assign netclass…. Netclasses can also be assigned in the schematic using netclass directives or labels instead of pattern-based assignments.

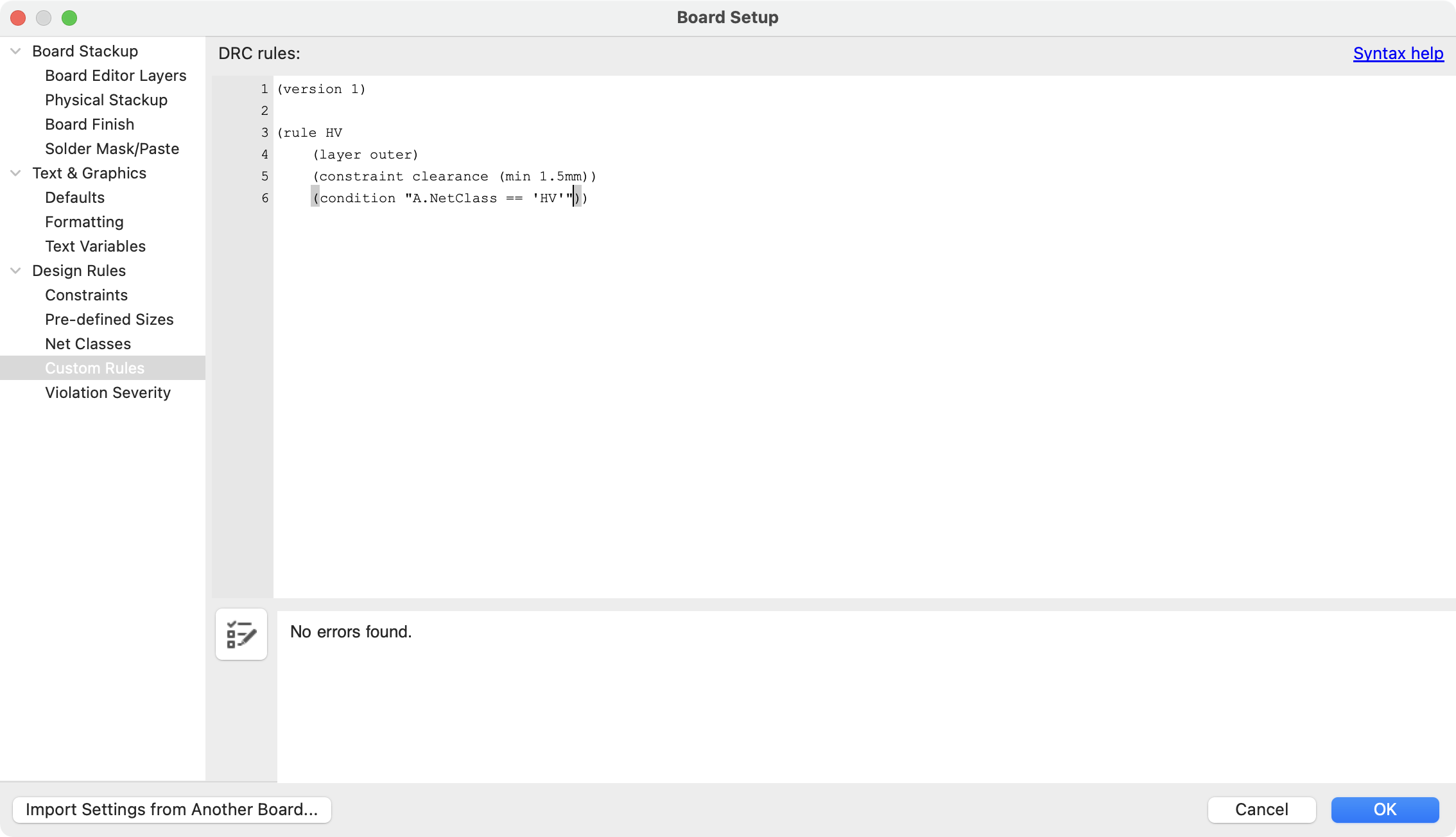

Custom Rules

The Custom Rules section contains a text editor for creating design rules using the custom rules language. Custom rules are used to create specific design rule checks that are not covered by the basic constraints or net class settings.

Custom rules will only be applied if there are no errors in the custom rules definitions. Use the Check Rule Syntax button to test the definitions and fix any problems before closing Board Setup.

See Custom Design Rules in the Advanced Topics chapter for more information on the custom rules language as well as example rules.

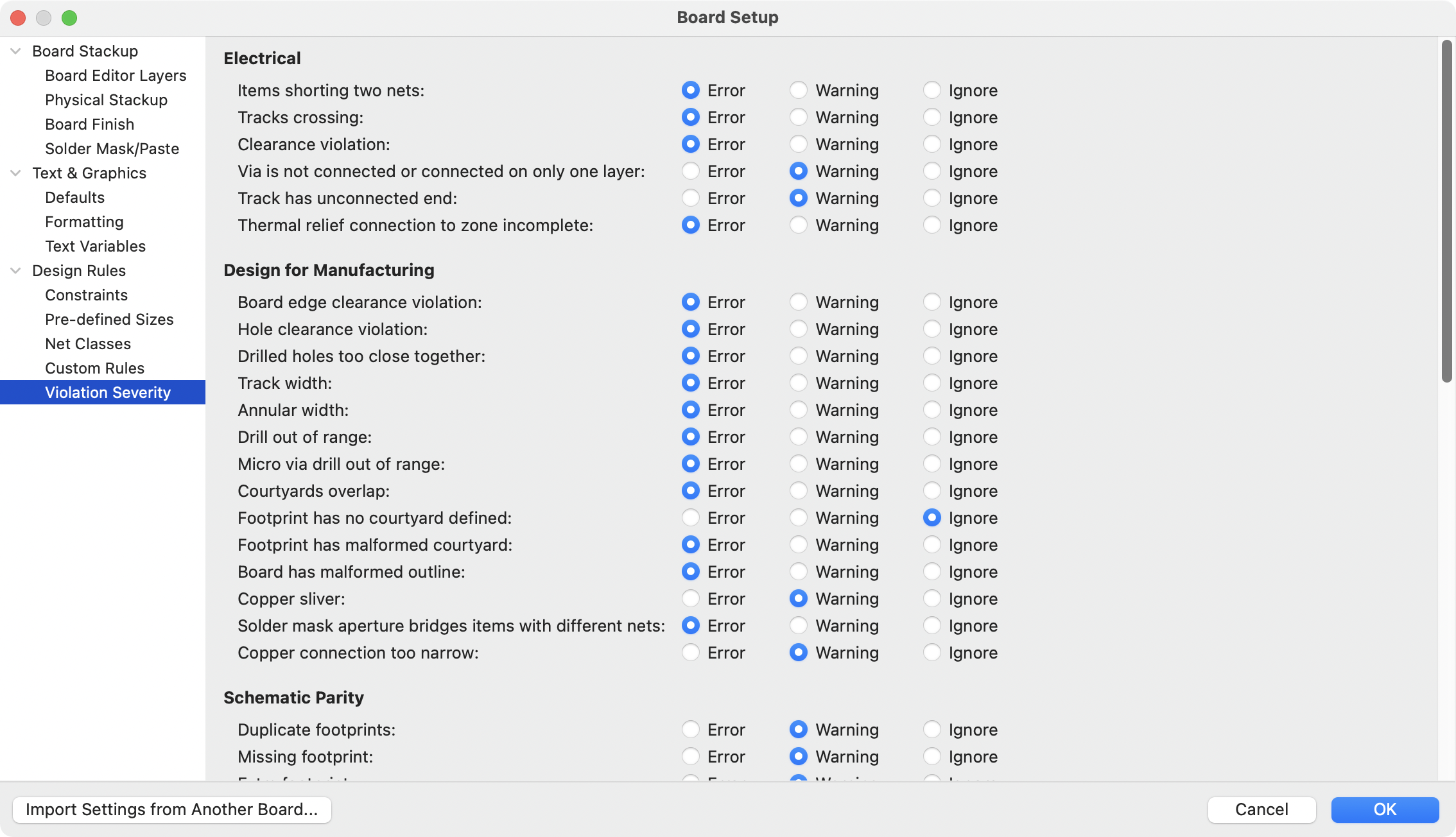

Violation Severity

The Violation Severity section allows you to configure the severity of each type of design rule check. Each rule may be set to create an error marker, a warning marker, or no marker (ignored).

| Individual rule violations may be ignored in the Design Rule Checker. Setting a rule to Ignore in the Violation Severity section will completely disable the corresponding design rule check. Use this setting with caution. |

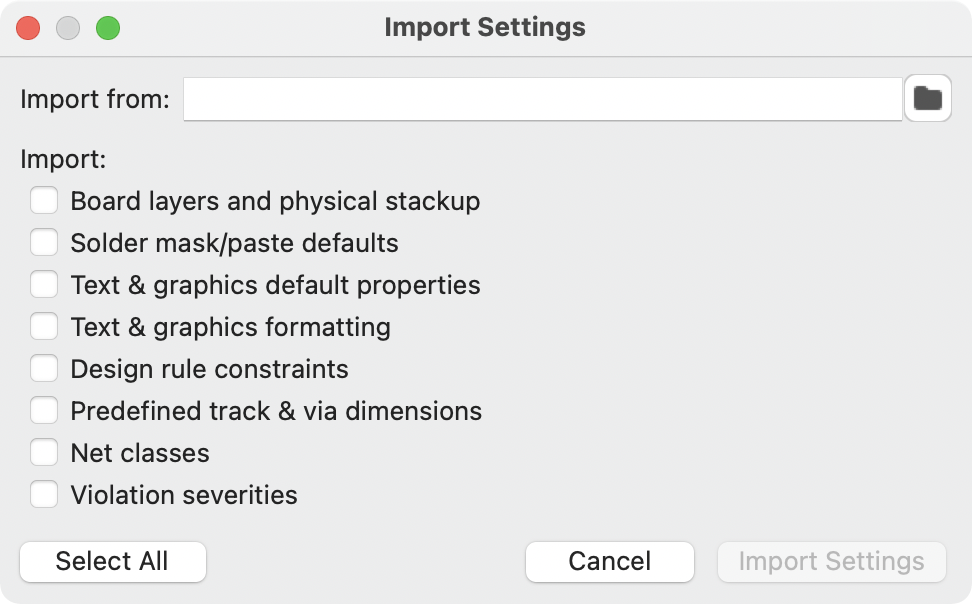

Importing settings

You can import part or all of the board setup from an existing board. This technique can be used to create a "template" board that has the settings you want to use on multiple designs, and then importing these settings from the template board into each new board rather than entering them manually.

To import settings, click the Import Settings from Another Board… button at the bottom of the

Board Setup dialog and then choose the kicad_pcb file you want to import from. Select which

settings you want to import and the current settings will be overwritten with the values from the

chosen board.

Editing a board

Placement and drawing operations

Placement and drawing tools are located in the right toolbar. When a tool is activated, it stays active until a different tool is selected or the tool is canceled with the Esc key. The selection tool is always activated when any other tool is canceled.

Some toolbar buttons have more than one tool available in a palette. These tools are indicated

with a small arrow in the lower-right corner of the button:

To show the palette, you can click and hold the mouse button on the tool or click and drag the mouse. The palette will show the most recently used tool when it is closed.

|

Selection tool (the default tool). |

|

Local ratsnest tool: when the board ratsnest is hidden, selecting footprints with this tool will show the ratsnest for the selected footprint only. Selecting the same footprint again will hide its ratsnest. The local ratsnest setting for each footprint will remain in effect even after the local ratsnest tool is no longer active. |

|

Footprint placement tool: click on the board to open the footprint chooser, then click again after choosing a footprint to confirm its location. |

|

Route tracks / route differential pairs: These tools activate the interactive router and allow placing tracks and vias. The interactive router is described in more detail in the Routing Tracks section below. |

|

Tune length: These tools allow you to tune the length of single tracks or the length or skew of differential pairs, after they have been routed. See the Routing Tracks section for details. |

|

Add vias: allows placing vias without routing tracks. Vias placed on top of tracks using this tool will take on the net of the closest track segment and will become part of that track (the via net will be updated if the pads connected to the tracks are updated). Vias placed anywhere else will take on the net of a copper zone at that location, if one exists. These vias will not automatically take on a new net if the net of the copper zone is changed. |

|

Add filled zone: Click to set the start point of a zone, then configure its properties before drawing the rest of the zone outline. Zone properties are described in more detail below. |

|

Add rule area: Rule areas, formerly known as keepouts, can restrict the placement of items and the filling of zones and can also define named areas to apply specific custom design rules to. |

|

Draw lines. Note: Lines are graphical objects and are not the same as tracks placed with the Route Tracks tool. Graphical objects cannot be assigned to a net. |

|

Draw arcs: pick the center point of the arc, then the start and end points. By right clicking this button, you can change the arc editing mode between a mode that maintains the existing arc center and a mode that maintains the arc radius. |

|

Draw rectangles. Rectangles can be filled or outlines. |

|

Draw circles. Circles can be filled or outlines. |

|

Draw graphical polygons. Polygons can be filled or outlined. Note: Filled graphical polygons are not the same as filled zones: graphical polygons cannot be assigned to a net and will not keep clearance from other items. |

|

Add bitmap image. |

|

Add text. |

|

Add a textbox. |

|

Add dimensions. Dimension types are described in more detail below. |

|

Deletion tool: click objects to delete them. |

|

Set drill/place origin (used for fabrication outputs) or grid origin. |

|

Interactively measure the distance between two points. |

Snapping

When moving, dragging, and drawing board elements, the grid, pads, and other elements can have snapping points depending upon the settings in the user preferences. In complex designs, snap points can be so close together that it makes the current tool action difficult. Both grid and object snapping can be disabled while moving the mouse by using the modifier keys in the table below.

| Modifier Key | Effect |

|---|---|

Ctrl |

Disable grid snapping. |

Shift |

Disable object snapping. |

Editing object properties

All objects have properties that are editable in a dialog. Use the hotkey E or select Properties from the right-click context menu to edit the properties of selected item(s). You can only open the properties dialog if all the items you have selected are of the same type. To edit the properties of different types of items at one time, see the section below on bulk editing tools.

In properties dialogs, any field that contains a numeric value can also accept a basic math

expression that results in a numeric value. For example, a dimension may be entered as 2 * 2mm,

resulting in a value of 4mm. Basic arithmetic operators as well as parentheses for defining

order of operations are supported.

Working with footprints

Adding footprints to the board

Footprints are automatically added to the board when the PCB is updated from the schematic. The footprint associated with each schematic symbol is added to the board if it is not already present, and each footprint pad is associated with the corresponding symbol pin’s net. Symbol pins are matched to footprint pads by pin/pad number.

When footprints are added to the board after an update from the schematic, they are grouped by schematic sheet and by geographical location in the schematic. They are initially attached to the cursor; you can place them by clicking in the desired location.

You can also add footprints to the board manually using the Add Footprint tool (A or the

![]() button). Note that footprints added in this way will not be

automatically associated with a symbol or have nets assigned to their pads, and subsequent updates

from the schematic will remove these unassociated footprints unless the footprint is locked or the

Delete footprints with no symbols option is unchecked in the Update PCB From Schematic dialog.

For these reasons, it is usually recommended to avoid manually adding footprints to the board.

Manually adding footprints is necessary for PCB-only workflows, and can

also be useful for adding logos or other footprints that do not need a corresponding schematic

symbol.

button). Note that footprints added in this way will not be

automatically associated with a symbol or have nets assigned to their pads, and subsequent updates

from the schematic will remove these unassociated footprints unless the footprint is locked or the

Delete footprints with no symbols option is unchecked in the Update PCB From Schematic dialog.

For these reasons, it is usually recommended to avoid manually adding footprints to the board.

Manually adding footprints is necessary for PCB-only workflows, and can

also be useful for adding logos or other footprints that do not need a corresponding schematic

symbol.

Placing and moving footprints

Once footprints have been added to the board, you can reposition them in many ways.

The Move command (M) moves a footprint or a selection of footprints, ignoring any connected track segments that are not selected. No DRC checking is done when moving footprints with the Move command.

There is a reference point for the move operation, which is the point in the footprint which attaches to the cursor and therefore the point in the footprint that snaps to the grid and to other objects. The reference point during a move is determined by the location of the cursor when the Move command is initiated. If the cursor is over a pad, the pad’s center will be used as the reference point. If the cursor is not over a pad, the footprint’s anchor (coordinate origin point) will be used. To select an arbitrary snapping point, you can use the Move With Reference command instead of the regular Move command (right click → Positioning Tools → Move with Reference). After initiating the command, click on the desired reference point; KiCad will then begin the move with that point as the reference.

You can also use the Drag command (D) to move the selected footprint using the interactive router, maintaining all track connections to the footprint. Dragging footprints behaves like the Highlight Collisions router mode: obstacles will not be avoided or shoved, only highlighted. Only one footprint at a time can be dragged.

Flip a footprint to the opposite side of the board with the F hotkey. Any parts of the footprint on a front layer will be swapped to the corresponding back layer, and vice versa.

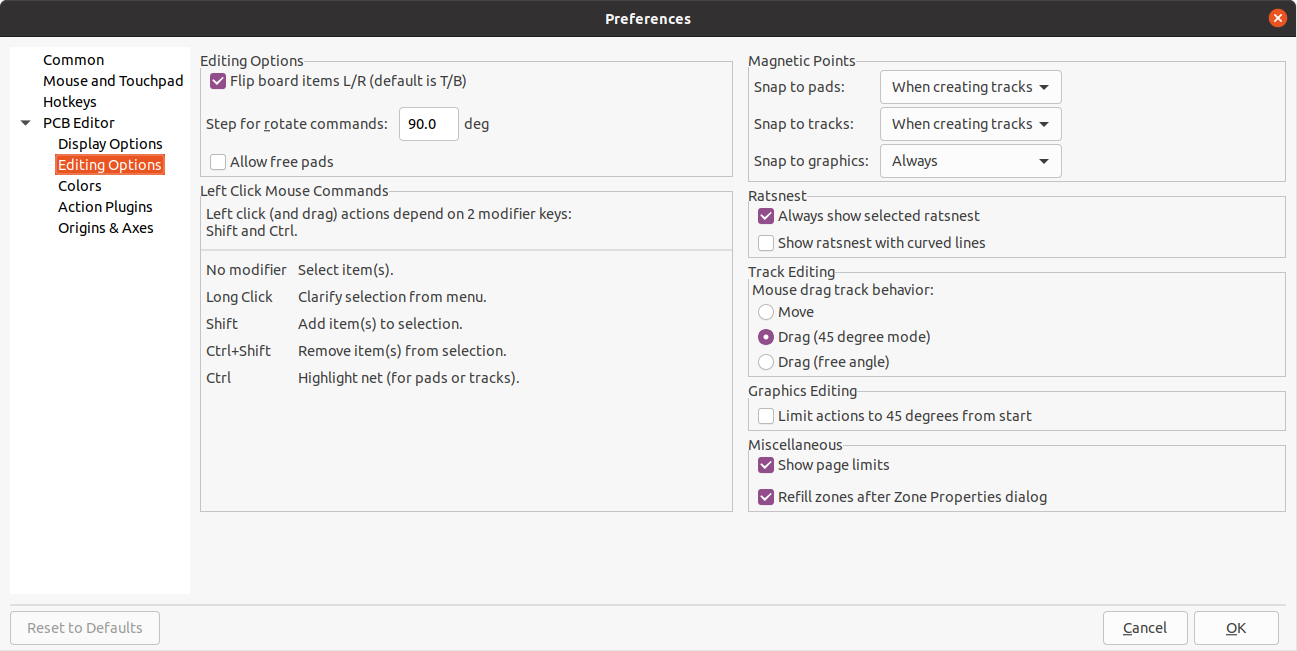

Rotate a footprint counter-clockwise using the R hotkey, or clockwise using Shift+R. By default, footprints are rotated by 90 degrees every time the rotate command is used, but you can configure the rotation angle step in Preferences → PCB Editor → Editing Options.

You can directly set a footprint’s exact absolute position, rotation angle, and PCB side using either the Footprint Properties dialog or the Properties panel.

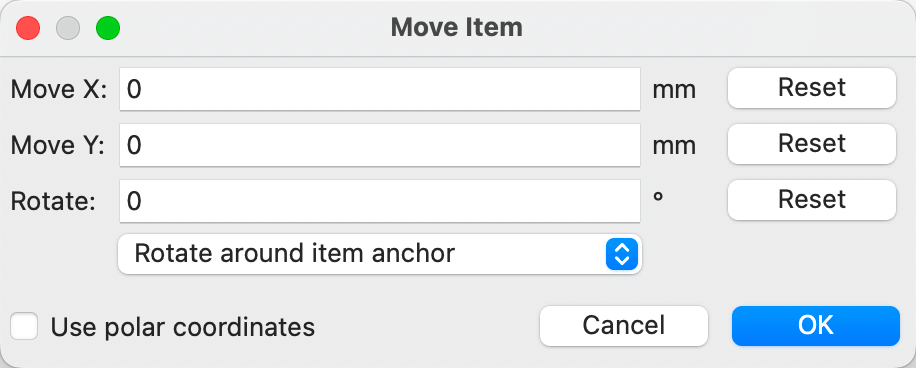

To reposition a footprint relative to its current position, use the Move Exactly tool (Shift+M). The dialog lets you specify an X and Y translation, as well as a rotation, that will be applied to the footprint. The rotation can be performed relative to either the footprint’s anchor, the local coordinate origin, or the drill/place origin. You can also use polar coordinates instead of Cartesian coordinates.

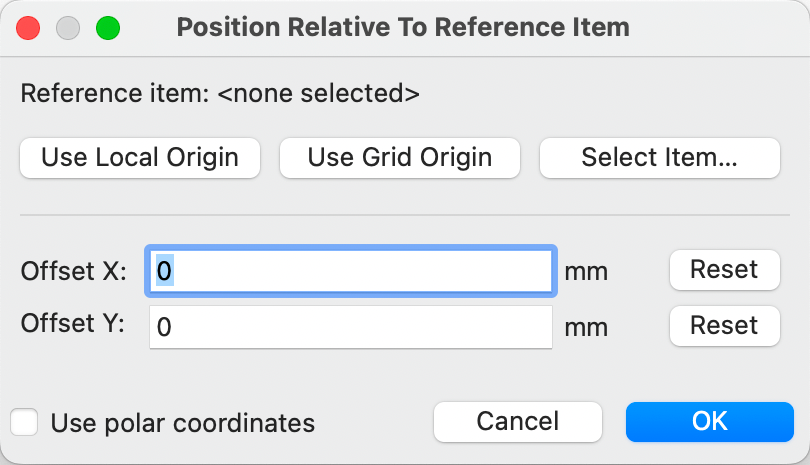

To position a footprint relative to another object, you can use the Position Relative tool (Shift+P). With this tool, you select a reference point for the move, which can be the local origin, the grid origin, or another arbitrary point, such as a pad in another footprint. The selected footprint is moved to the specified offset from the reference point.

You can swap the position of two selected footprints using the Swap command (Shift+S). The first footprint is assigned the location, rotation, and board side of the second footprint, and vice versa. If there are more than two footprints selected, the locations are cycled: the last footprint gets the position of the first footprint, the first footprint gets the location of the second, and so on.

There are several convenience features that make it easier to find, select, and move specific footprints or footprints related to another footprint.

The Get and Move Footprint command (T) prompts you to choose a footprint from a list or by typing a reference designator. KiCad then attaches the chosen footprint to your cursor for a move operation.

There are two commands to select other footprints that need to be connected to the selected footprint but don’t yet have routed connections. The Select All Unconnected Footprints command (O) selects all footprints that have ratsnest lines to the currently selected footprints. The command can be executed repeatedly to further expand the selection based on the newly selected items. The Grab Nearest Unconnected Footprint command (Shift+O) selects the closest footprint with ratsnest lines to the currently selected footprint, and additionally begins to move it. If there are multiple footprints initially selected, the command will act like the Move Individually command described below, individually moving the closest unconnected footprint for each of the initially selected footprints.

You can select footprints based on their schematic sheet using the right click → Select → Items in Same Hierarchical Sheet command, which selects all other footprints that are in the same schematic sheet as the originally selected footprint.

If you want to move multiple selected footprints in sequence, use the Move Individually command (Ctrl+M). After triggering the command, KiCad will begin moving the first selected footprint. After you click to place the footprint, KiCad will immediately start moving the next footprint, in the same order that you selected the footprints. You can skip moving a footprint by pressing Tab, commit the current move and skip any remaining moves by double-clicking, or cancel all moves (including those already completed) by pressing Esc.

If you want to move a collection of footprints at once into one area, the Pack and Move Footprints command (P) closely packs the selected footprints together and moves them as a block.

| Move Individually and Pack and Move Footprints are useful in combination with other selection convenience features, such as cross-selection from the schematic or the advanced footprint selection features described above. For example, you could select a group of bypass capacitors in the Schematic Editor, switch to the PCB Editor where the corresponding footprints are now selected, and then use Move Individually to quickly place all of the bypass capacitor footprints close to their respective ICs. Alternatively, you could use one of the other selection tools, such as Select All Unconnected Footprints, to select many footprints from all over the board, then use Pack and Move Footprints to quickly put them all into a small area. |

Finally, KiCad can automatically place footprints onto the board. The auto-place function attempts to optimally place footprints to simplify ratsnest connections to other footprints. You can auto-place the selected footprints with Place → Auto-Place Footprints → Place Selected Footprints, or auto-place all footprints outside of the board outline with Place → Auto-Place Footprints → Place Off-Board Footprints.

Footprint Properties

| This section of the KiCad documentation has not yet been written. We appreciate your patience as our small team of volunteer documentation writers work to update and expand the documentation. |

Editing Footprints

| This section of the KiCad documentation has not yet been written. We appreciate your patience as our small team of volunteer documentation writers work to update and expand the documentation. |

Working with pads

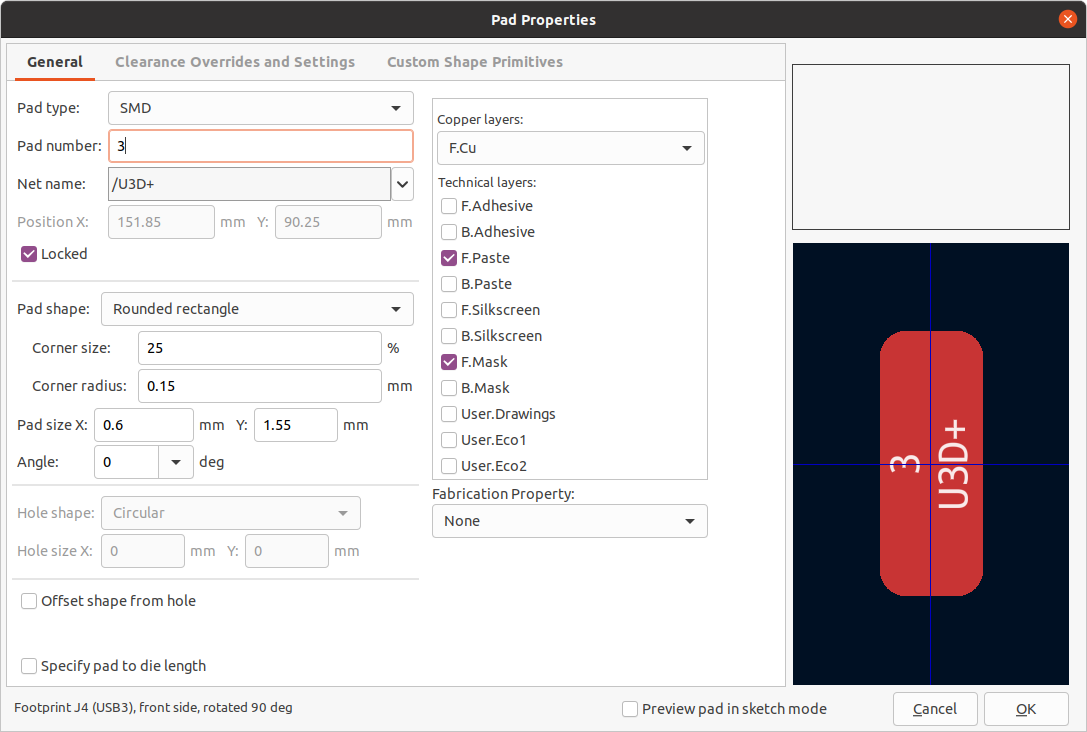

The properties of each individual pad of a footprint can be inspected and edited after placing the footprint on the board. In other words, it is possible to override the design of an individual footprint pad in a specific instance of the footprint on the board, if the footprint design in the library is not appropriate. For example, you may wish to remove the solder paste aperture for a pad that needs to remain unsoldered in a specific design, or you may wish to move the location of a through-hole pad for an axial-lead resistor in order to fit a specific design.

| By default, the position of all footprint pads are locked, so it is possible to edit the pad properties but not move the pad’s location relative to the rest of the footprint. Pads may be unlocked to allow free movement, which can be useful for certain applications (such as through-hole footprints with varying lead positions) but is generally never recommended for surface-mount footprints. |

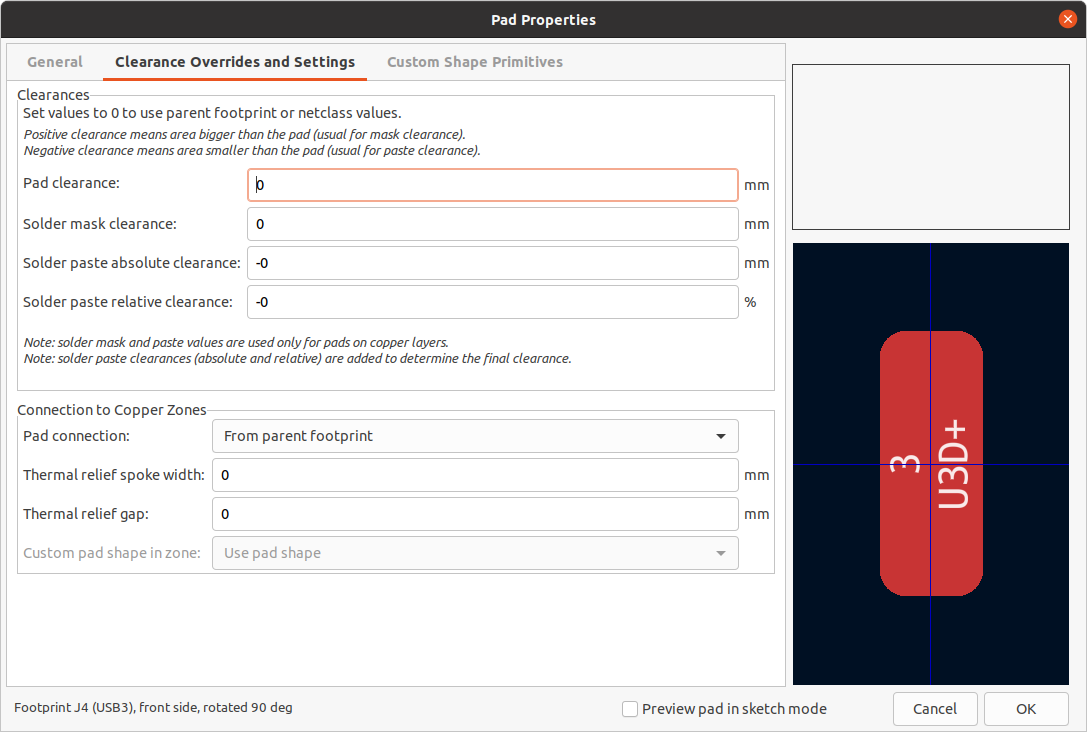

The pad properties dialog is opened through the context menu or default hotkey E when a pad is selected. Note that KiCad assumes that if you click near a pad, you are probably trying to select the entire footprint rather than a single pad. To select a single pad, make sure to click inside the pad area, or turn off the Footprints setting in the selection filter (and make sure the Pads setting is turned on) to prevent accidental selection of the entire footprint rather than a specific pad.

The General tab of the pad properties dialog shows the physical properties of the pad, including its geometry, shape, and layer settings.

Pad type: this setting controls which features are enabled for the pad:

SMD pads are electrically-connected and have no hole. In other words, they exist on a single copper layer.

Through-hole pads are electrically-connected and have a plated hole. The hole exists on every layer, and the copper pad exists on multiple layers (see Copper layers setting below).

Edge Connector pads are SMD pads that are allowed to overlap the board outline on the Edge.Cuts layer.

NPTH, Mechanical pads are non-plated through holes that do not have an electrical connection.

SMD Aperture pads are pads that have no hole and no electrical connection. These can be used to add specific designs to a technical layer, for example a paste or solder mask aperture.

The Copper layers setting controls which copper layers will have a shape associated with the pad.

For SMD pads, the options are F.Cu or B.Cu, controlling whether the pad sits on the front or the back of the board relative to the footprint’s location. In other words, if a pad is set to exist on B.Cu in its properties, and the footprint is flipped to the back of the board, that pad will now exist on F.Cu, because it also has been flipped.

For through-hole pads, it is possible to remove the pad shape from copper layers where the pad is not electrically connected to other copper (tracks or filled zones). Setting the copper layers to connected layers only will remove the pad shape from any unconnected layers, and setting to F.Cu, B.Cu, and connected layers will remove the pad shape from any internal unconnected layers. This can be useful in dense board designs to increase the routable area on internal layers.

The Technical layers checkboxes control which technical layers will have an aperture added with the pad’s shape. By default, pads have apertures on the paste and mask layers matching their copper layer.

| It is not possible to define a different pad shape or size on different copper layers in the current version of KiCad. |

Specify pad to die length: This setting allows a length to be associated with this pad that will be added to the routed track length by the track length tuning tools and the Net Inspector. This can be used to specify internal bondwire lengths for more accurate length matching, or in other situations where the electrical length of a net is longer than the length of the routed tracks on the board.

The aperture appearing on any technical layer will have the same shape and size as the pad shape on the copper layer(s). In the PCB manufacturing process, the manufacturer will often change the relative size of mask and paste apertures relative to the copper pad size, but since this size change is specific to a manufacturing process, most manufacturers expect the design data to be provided with the apertures set to the same size as the copper pads. For specific situations where you need to oversize or undersize a technical layer aperture in the design data, you can use the settings in the Overrides tab.

Pad clearance controls the minimum clearance between the pad and any copper shape (tracks,

vias, pads, zones) on a different net. This value is normally set to 0 which will cause the pad

clearance to be inherited from any clearance override set on the footprint, or the board’s design

rules and netclass rules if the footprint clearance is also set to 0.

Solder mask clearance controls the size difference between the pad shape and the aperture shape

on the F.Mask and B.Mask layers. A positive number means the solder mask aperture will be larger

than the copper shape. This number is an inflation applied to all directions. For example, a

value of 0.1mm here will cause the solder mask aperture to be inflated by 0.1mm, meaning that

there will be an 0.1mm border on all sides of the pad and the solder mask opening will be 0.2mm

wider than the pad when measured along a given axis.

Solder paste absolute clearance controls the size difference between the pad shape and the aperture shape on the F.Paste and B.Paste layers. Its behavior is otherwise identical to the behavior of the solder mask clearance setting.

Solder paste relative clearance allows setting a solder paste clearance value as a percentage of the pad size rather than an absolute distance value. If both relative and absolute clearances are specified, they are added together to determine the solder paste aperture size.

The Overrides tab also has controls for how the pad connects to any copper zone that overlaps it and shares its net.

Pad connection controls whether the pad will have a solid, thermal relief, or no connection to the zone. Like the other overrides, this one may be set for an individual pad or for an entire footprint. The default setting for this control is From parent footprint, and the default footprint setting is to use the connection mode specified in the zone properties.

Thermal relief spoke width controls the width of the spokes generated when the zone connection mode is Thermal Relief.

Thermal relief gap controls the length of the thermal spokes, or the gap between the pad’s shape and the filled copper area of the zone.

Custom pad shape in zone controls the behavior of the zone filler when the pad uses a custom shape rather than one of the default shapes. This can be used to achieve different results when using thermal reliefs and custom pad shapes.

Working with zones

Copper zones, also sometimes called copper pours or fills by other EDA tools, are solid or hatched areas of copper assigned to a particular net that automatically keep clearance from other copper objects. Zones are commonly used to fill in all free space on a board layer (or a portion of a layer) in order to create ground and power planes, carry high currents, or to provide shielding.

| Some EDA tools have separate tools for creating "plane layers" and for creating copper zones on signal layers. In KiCad, the Copper Zone tool is used for both these applications. |

Zones are defined by a polygonal outline that defines the maximum extent of the filled copper area. This outline does not represent physical copper and will not appear in exported manufacturing data. The actual copper areas of the zone must be filled each time the outline, or any objects inside the outline, are modified. The filling process may be run on a single zone, or on all zones in a board (default hotkey B). Zones may be unfilled (default hotkey Ctrl+B) to improve performance and reduce visual clutter while editing large boards.

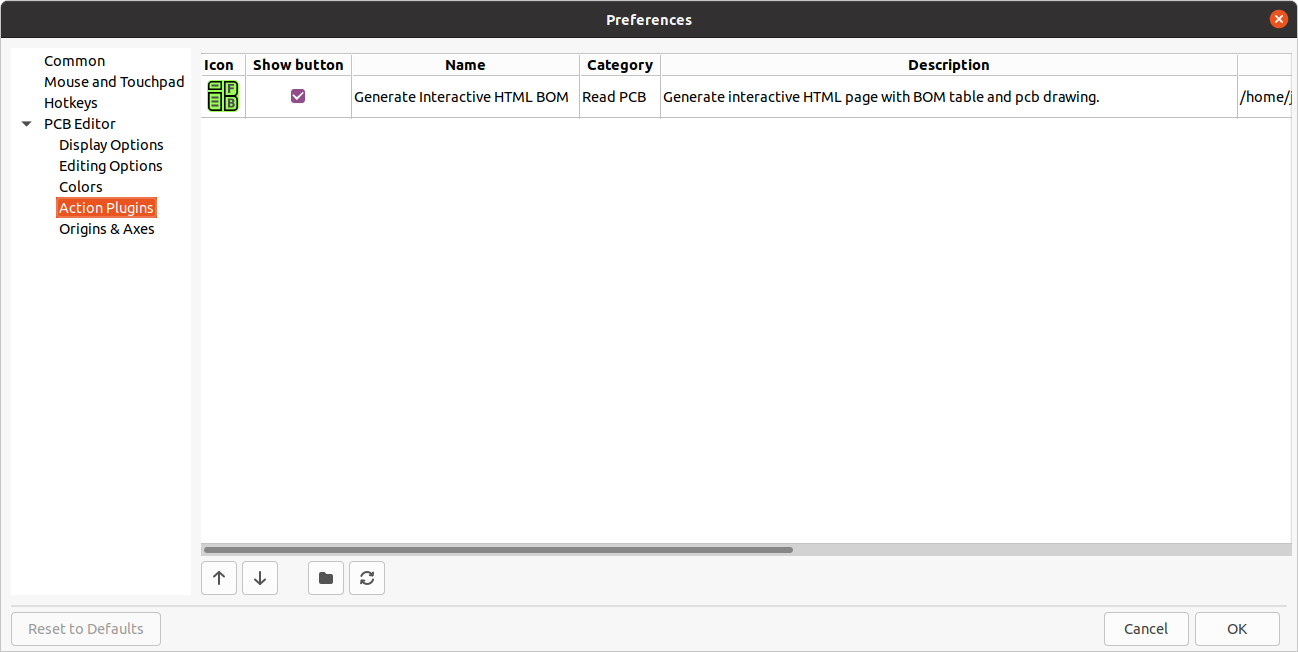

| By default, zone filling is a manual process rather than occurring every time an object changes that would result in a change to the zone copper. This is because zone filling can be a slow process on older computers or very large designs. It is important to make sure zone fills are up-to-date before generating outputs. KiCad will check that zones have been updated and warn you before generating outputs or running DRC when zones have not yet been refilled. You can optionally enable automatic zone-filling in the Preferences dialog (PCB Editor → Editing Options → Miscellaneous → Auto-refill zones). |

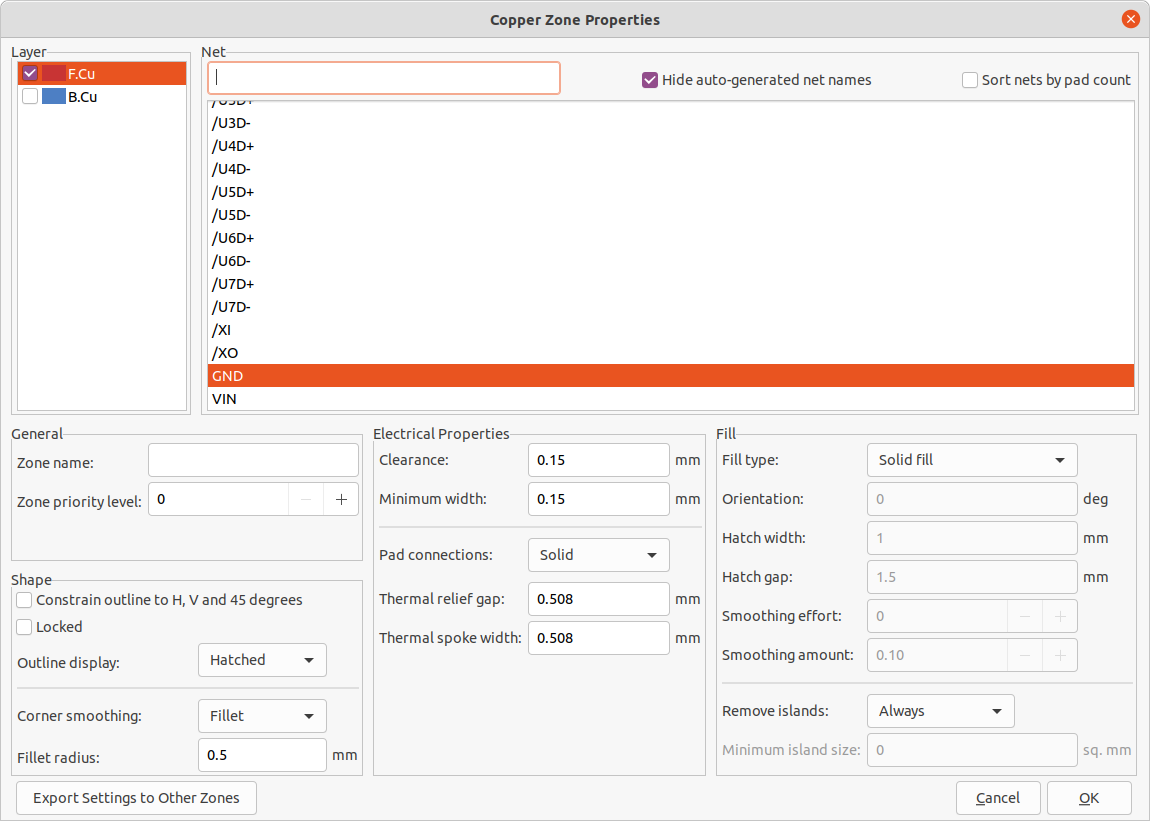

To draw a zone, click the Add Filled Zone tool (![]() ) on the right

toolbar, or use default hotkey Ctrl+Shift+Z. Click to choose the first point of the zone

outline. The Zone Properties dialog will appear, allowing you to choose the zone net and other

properties. These properties may be edited at any time, so it is not critical to choose them all

correctly at first. Accept the dialog and continue placing points to define the zone outline. To

finish the zone, double-click to set the last point. Zone outline points may be modified like

graphic polygons, by dragging the square handles to move a corner or dragging the circular handles

to move an edge. To edit the zone’s properties, use hotkey E or select Properties from the

context menu.

) on the right

toolbar, or use default hotkey Ctrl+Shift+Z. Click to choose the first point of the zone

outline. The Zone Properties dialog will appear, allowing you to choose the zone net and other

properties. These properties may be edited at any time, so it is not critical to choose them all

correctly at first. Accept the dialog and continue placing points to define the zone outline. To

finish the zone, double-click to set the last point. Zone outline points may be modified like

graphic polygons, by dragging the square handles to move a corner or dragging the circular handles

to move an edge. To edit the zone’s properties, use hotkey E or select Properties from the

context menu.

Layer: A single zone object can create filled copper on one or more copper layers. Check the box next to each copper layer that this zone outline should fill on. The copper on each layer will be filled independently, but all layers will share the same net.

Net: Select the electrical net that the zone copper should be connected to. It is possible to create zones with no net assignment. Zones with no net will keep clearance from any copper objects on any net.

Zone name can be used to assign a specific name to a zone. This name can be used to refer to the zone in custom DRC rules.

Zone priority level determines the order in which multiple zones on a single layer are filled. The highest priority level zone on a given layer will be filled first. Lower-priority zones will keep clearance to the filled areas of higher-priority zones. Two zones on the same layer with the same priority level will overlap (short-circuit) with each other, unless they are assigned different nets. When two zone outlines with the same priority and different nets touch, one zone will maintain clearance to the other so that they don’t short.

Constrain outline to H, V and 45 degrees controls the initial behavior of the zone outline drawing tool. When this option is enabled, the zone outline will be restricted to 45-degree angles. Note that after the zone outline has been created, this option has no effect. Outline points may be modified freely after creation.

Locked controls whether or not the zone outline object is locked. Locked objects may not be manipulated or moved, and cannot be selected unless the Locked Items option is enabled in the Selection Filter panel.

Outline display controls how the zone outline is drawn on screen. In Line mode, only the border lines of the outline are drawn. In Hatched mode, hatch lines are drawn on the inside of the outline border for a short distance, to make the zone outline more apparent. In Fully Hatched mode, hatch lines are drawn across the entire inside of the zone outline.

Corner smoothing controls the behavior of the filled copper areas at corners of the outline. Corners can be smoothed by a chamfer or fillet, or can extend all the way to the outline corner if smoothing is disabled.

| By default, chamfers and fillets are not added to inside corners of the zone outline, because this would result in filled copper extending outside the outline. If smooth inside corners are desired, enable the Allow fillets outside zone outline option in the Constraints section of the Board Setup dialog. |

Clearance controls the minimum clearance the filled areas of this zone will keep from other copper objects. Note that if two clearance values are in conflict, the larger clearance value will be used. For example, if a zone is set to use 0.2mm clearance but its netclass is set to use 0.3mm clearance, the result will be an 0.3mm clearance.

Minimum width controls the minimum size of narrow necks of copper created inside the zone. Any copper areas that would be below this minimum width are removed during the filling process.

Pad connection controls the way that the filled zone areas will connect to footprint pads on the same net. Solid connections will result in the copper completely overlapping the pads. Thermal reliefs will result in small copper spokes connecting the pad to the rest of the copper zone, increasing the thermal resistance between the pad and the rest of the zone. This can be useful for hand soldering. Reliefs for PTH will apply thermal reliefs to plated through-hole pads and use solid connections for surface mount pads. None will result in the zone not connecting to any pads on the same net.

Thermal relief gap controls the distance maintained between any pad and the copper zone when the pad connection mode is set to generate thermal reliefs.

Thermal spoke width controls the width of the "spokes", or short copper segments connecting the pad to the rest of the copper zone.

Fill type controls how the copper zone is filled: the default is solid fill, which will result in copper filling in all available space within the zone outline. The zone can also be set to fill a hatch pattern, which will fill the area with a pattern that contains less copper. This can be useful for flexible printed circuits and other specialty applications.

Orientation controls the angle of the hatch pattern lines. An orientation of 0 degrees will result in the hatch pattern using horizontal and vertical lines.

Hatch width controls the width of each line in the hatch pattern.

Hatch gap controls the distance between each line in the hatch pattern.

Smoothing effort controls the style of smoothing applied to the hatch pattern. A value of 0 will result in no smoothing, and a value of 3 will result in the finest smoothing. Higher values will result in longer processing time and larger Gerber files.

Smoothing amount is a ratio that controls the size of the smoothing chamfers or fillets that are generated when smoothing effort is set to a value other than 0. An amount of 0.0 results in no smoothing, and a value of 1.0 results in maximum smoothing (in other words, a chamfer or fillet equal to half of the hatch gap).

Remove islands controls the behavior of isolated copper areas, also called islands, after the initial zone fill. When this is set to always, isolated areas inside the zone are removed. When set to never, isolated areas are left alone, and will result in copper areas that are not connected to the rest of the net. When set to below area limit, a minimum island size can be specified, and islands below this threshold will be removed.

| Regardless of the remove islands setting, islands are never removed from zones that are electrically unconnected. In other words, islands are only removed from zones that have at least one electrical connection. |

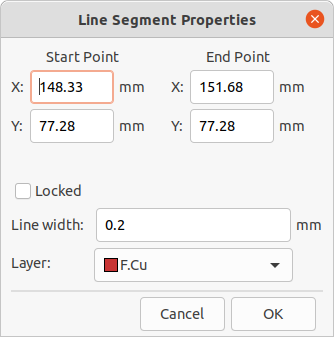

Graphical objects

Graphical objects (lines, arcs, rectangles, circles, polygons, and text) can exist on any layer but

cannot be assigned to a net. Rectangles, circles, and polygons can be set to be filled or outlines

in their properties dialogs. The line width property will control the width of the outline even

for filled shapes. Line width can be set to 0 for filled shapes to disable the outline.

Creating graphical shapes

The right toolbar can be used to create lines (![]() , default hotkey

Ctrl+Shift+L), arcs (

, default hotkey

Ctrl+Shift+L), arcs (![]() , default hotkey Ctrl+Shift+A),

rectangles (

, default hotkey Ctrl+Shift+A),

rectangles (![]() ), circles (

), circles (![]() ,

default hotkey Ctrl+Shift+C), and polygons

(

,

default hotkey Ctrl+Shift+C), and polygons

(![]() , default hotkey Ctrl+Shift+P).

, default hotkey Ctrl+Shift+P).

Rectangles, circles, and polygons can be filled shapes or outlines. The line width option controls the width of the outline. The outline width extends on both sides of the "ideal" shape of the graphic object. For example, a graphic circle that is defined to have 2mm radius and 0.2mm line width will consist of a torus with an outer radius of 2.2mm and inner radius of 1.8mm. If the filled shape option is enabled and the line width is set to 0, the shape will be a filled circle with 2mm radius.

Arcs have two editing modes, which are selectable in Preferences →

PCB Editor → Editing Options or by right clicking the

![]() button on the right toolbar. The first mode

(keep arc center, adjust radius) maintains the position of the arc center as

as the arc endpoints or midpoint are dragged, changing the radius as necessary.

The second mode (keep arc endpoints or direction of starting point)

maintains the position of the arc endpoints and the arc’s direction of curvature

as the midpoint or center are dragged.

button on the right toolbar. The first mode

(keep arc center, adjust radius) maintains the position of the arc center as

as the arc endpoints or midpoint are dragged, changing the radius as necessary.

The second mode (keep arc endpoints or direction of starting point)

maintains the position of the arc endpoints and the arc’s direction of curvature

as the midpoint or center are dragged.

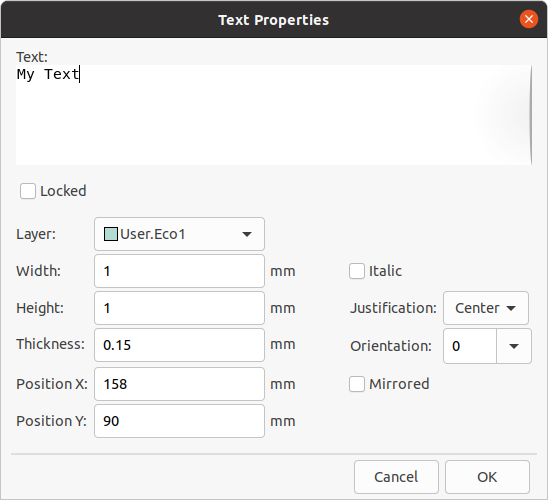

Creating text objects

Graphical text may be placed by using the (![]() ) icon in the right

toolbar or by keyboard shortcut Ctrl+Shift+T. Click to place the text origin, and then

edit the text and its properties in the dialog that will appear:

) icon in the right

toolbar or by keyboard shortcut Ctrl+Shift+T. Click to place the text origin, and then

edit the text and its properties in the dialog that will appear:

Text may be placed on any layer, but note that text on copper layers cannot be associated with a net and cannot form connections to tracks or pads. Copper zones will fill around the rectangular bounding box of text objects.

Text supports markup for superscripts, subscripts, overbars, evaluating project variables, and accessing symbol field values.

| Feature | Markup Syntax | Result |

|---|---|---|

Superscript |

|

textsuperscript |

Subscript |

|

textsubscript |

Overbar |

|

text |

|

variable_value |

|

|

field_value of symbol refdes |

| Variables must be defined in Board Setup before they can be used. There are also a number of built-in text variables. |

Board outlines (Edge Cuts)

KiCad uses graphical objects on the Edge.Cuts layer to define the board outline. The outline

must be a continuous (closed) shape, but can be made up of different types of graphical object such

as lines and arcs, or be a single object such as a rectangle or polygon. If no board outline is

defined, or the board outline is invalid, some functions such as the 3D viewer and some design rule

checks will not be functional.

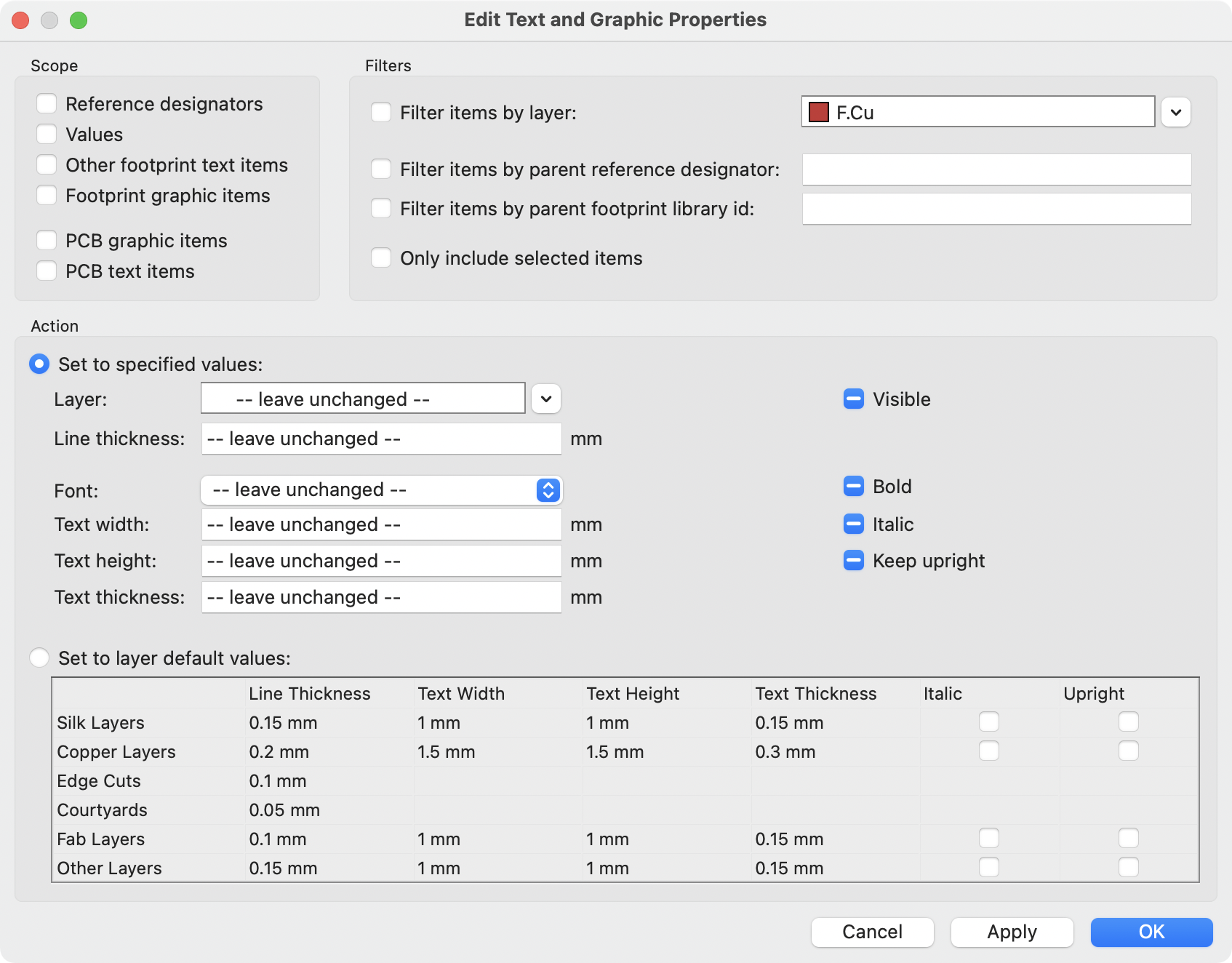

Bulk editing text and graphics

Properties of text and graphics can be edited in bulk using the Edit Text and Graphic Properties dialog (Tools → Edit Text and Graphic Properties…).

Scope and Filters

Scope settings restrict the tool to editing only certain types of objects. If no scopes are selected, nothing will be edited.

Filters restrict the tool to editing particular objects in the selected scope.

Objects will only be modified if they match all enabled and relevant filters

(some filters do not apply to certain types of objects. For example, parent

footprint filters do not apply to graphic items and are ignored for the purpose

of changing graphic properties). If no filters are enabled, all objects in the

selected scope will be modified. For filters with a text box, wildcards are

supported: * matches any characters, and ? matches any single character.

Filter items by layer filters to items on the specified board layer.

Filter other symbol fields by name filters to the specified symbol field.

Filter items by parent reference designator filters to fields in the footprint with the specified reference designator. Filter items by parent footprint library id filters to fields in footprint with the specified library identifier.

Only include selected items filters to the current selection.

Action

Properties for filtered objects can be set to new values in the bottom part of the dialog. Properties can be set to arbitrary values by selecting set to specified values or reset to their layer’s default value by selecting set to layer default values.

Drop-down lists and text boxes can be set to -- leave unchanged -- to preserve

existing values. Checkboxes can be checked or unchecked to enable or disable a

change, but can also be toggled to a third "leave unchanged" state.

All items can have their layer set.

Graphic items can have their line thickness modified.

Text properties that can be modified are font, text width, text height, text thickness (KiCad font only), emphasis (bold and italic), and orientation (keep upright). Footprint text can also have its visibility set.

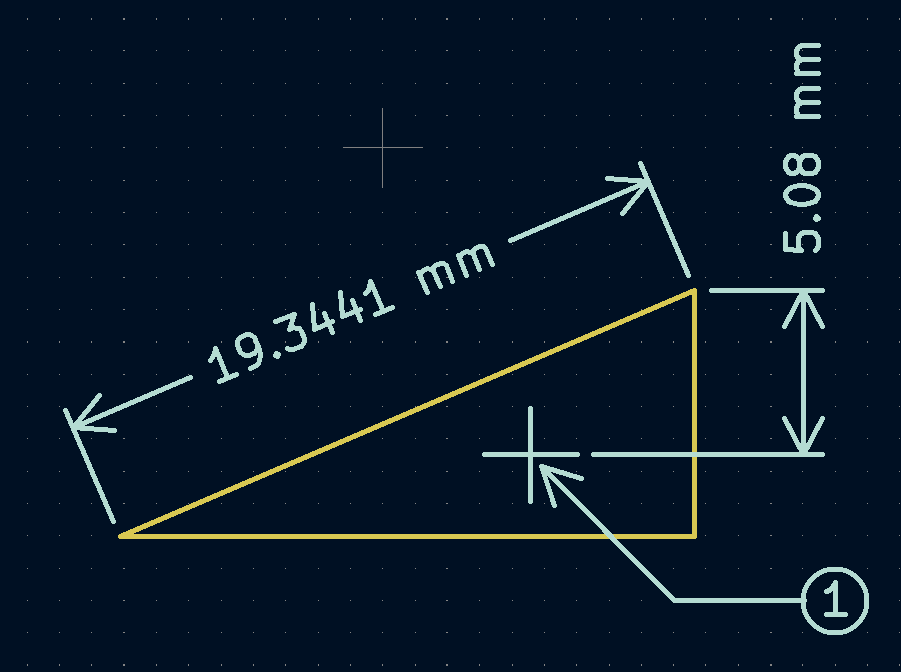

Dimensions

Dimensions are graphical objects used to show a measurement or other marking on a board design. They may be added on any drawing layer, but are normally added to one of the User layers. KiCad currently supports five different types of dimension: aligned, orthogonal, center, radial, and leader.

Aligned dimensions (![]() ) show a measurement of

distance between two points. The measurement axis is the line that connects those two points, and

the dimension graphics are kept parallel to that axis.

) show a measurement of

distance between two points. The measurement axis is the line that connects those two points, and

the dimension graphics are kept parallel to that axis.

Orthogonal dimensions (![]() ) also measure the

distance between two points, but the measurement axis is either the X or Y axis. In other words,

these dimensions show the horizontal or vertical component of the distance between two points.

When creating orthogonal dimensions, you can select which axis to use as the measurement axis based

on where you place the dimension after selecting the two points to measure.

) also measure the

distance between two points, but the measurement axis is either the X or Y axis. In other words,

these dimensions show the horizontal or vertical component of the distance between two points.

When creating orthogonal dimensions, you can select which axis to use as the measurement axis based

on where you place the dimension after selecting the two points to measure.

Center dimensions (![]() ) create a cross mark to

indicate a point or the center of a circle or arc.

) create a cross mark to

indicate a point or the center of a circle or arc.

Radial dimensions (![]() ) show a measurement between

a center point and the outside of a circle or arc. The center point is indicated by a cross.

) show a measurement between

a center point and the outside of a circle or arc. The center point is indicated by a cross.

Leader dimensions (![]() ) create an arrow with a leader line

connected to a text field. This text field can contain any text, and an optional circular or

rectangular frame around the text. This type of dimension is often used to call attention to parts

of the design for reference in fabrication notes.

) create an arrow with a leader line

connected to a text field. This text field can contain any text, and an optional circular or

rectangular frame around the text. This type of dimension is often used to call attention to parts

of the design for reference in fabrication notes.

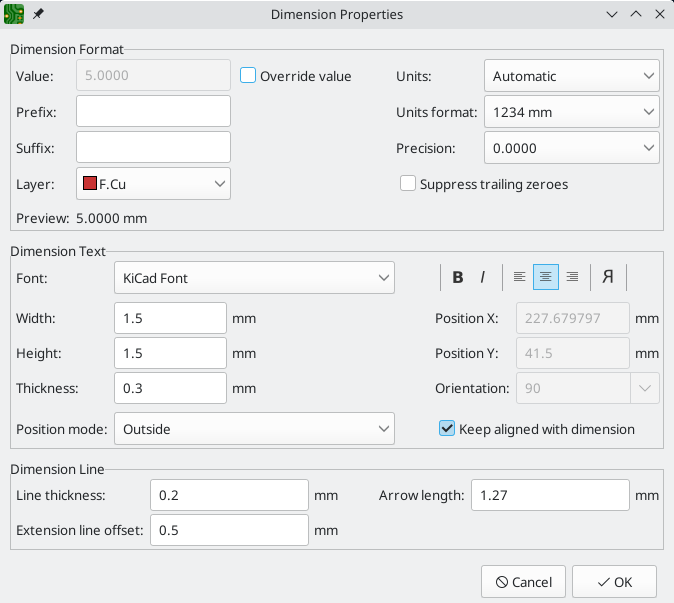

After creating a dimension, its properties may be edited (hotkey E) to change the format of the displayed number and the style of the text and graphic lines.

| You may customize the default style of newly-created dimension objects in the Text & Graphics Defaults section of the Board Setup dialog. |

Dimension format options

Override value: When enabled, you may enter a measurement value directly into the Value field that will be used instead of the actual measured value.

Prefix: Any text entered here will be shown before the measurement value.

Suffix: Any text entered here will be shown after the measurement value.

Layer: Selects which layer the dimension object exists on.

Units: Selects which units to display the measured value in. Automatic units will result in the dimension units changing when the display units of the board editor are changed.

Units format: Select from several built-in styles of unit display.

Precision: Select how many digits of precision to display.

Dimension text options

Most of the dimension text options are identical to those options available for other graphical text objects (see the Graphical Objects section above). Some specific options for dimension text are also available:

Position mode: Choose whether to position the dimension text manually, or to automatically keep it aligned with the dimension measurement lines.

Keep aligned with dimension: When enabled, the orientation of the dimension text will be adjusted automatically to keep the text parallel with the measurement axis.

Dimension line options

Line thickness: Sets the thickness of the graphical lines that make up a dimension’s shape.

Extension line offset: Sets the distance from the measurement point to the start of the extension lines.

Arrow length: Sets the length of the arrow segments of the dimension’s shape.

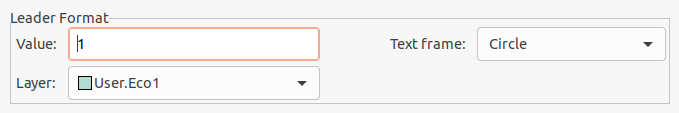

Leader options

Value: Enter the text to show at the end of the leader line.

Text frame: Select the desired border around the text (circle, rectangle, or none).

Routing tracks

KiCad features an interactive router that:

-

Allows manual or guided (semi-automatic) routing of single tracks and differential pairs

-

Enables modifications of existing designs by:

-

Re-routing existing tracks when they are dragged

-

Re-routing tracks attached to footprint pads when the footprint is dragged

-

-

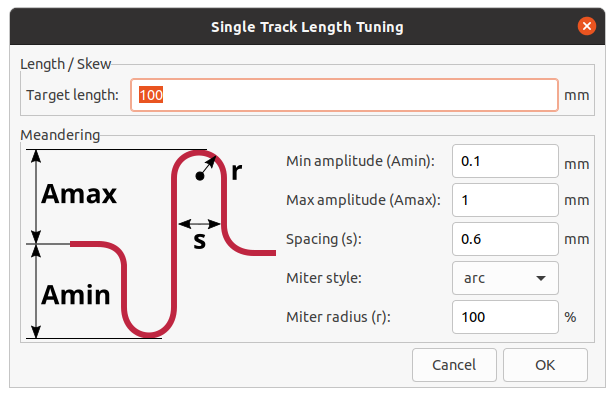

Allows tuning of track lengths and differential pair skew (phase) by inserting serpentine

tuning shapes for designs with tight timing requirements

By default, the router respects the configured design rules when placing tracks: the size (width) of new tracks will be taken from the design rules and the router will respect the copper clearance set in the design rules when determining where new tracks and vias can be placed. It is possible to disable this behavior if desired by using the Highlight Collisions router mode and turning on the Allow DRC Violations option in the router settings (see below).

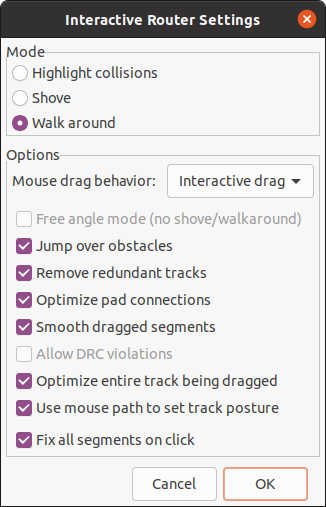

The router has three modes that can be selected at any time. The router mode is used for routing new tracks, but also when dragging existing tracks using the Drag (hotkey D) command. These modes are:

-

Highlight Collisions: in this mode, most of the router features are disabled and routing is fully manual. When routing, collisions (clearance violations) will be highlighted in green and the newly-routed tracks cannot be fixed in place if there is a collision unless the Allow DRC Violations option is turned on. In this mode, up to two track segments may be placed at a time (for example, one horizontal and one diagonal segment).

-

Shove: in this mode, the track being routed will walk around obstacles that cannot be moved (for example, pads and locked tracks/vias) and shove obstacles that can be moved out of the way. The router prevents DRC violations in this mode: if there is no way to route to the cursor position that does not violate DRC, no new tracks will be created.

-

Walk Around: in this mode, the router behaves the same as in Shove mode, except no obstacles will be moved out of the way.

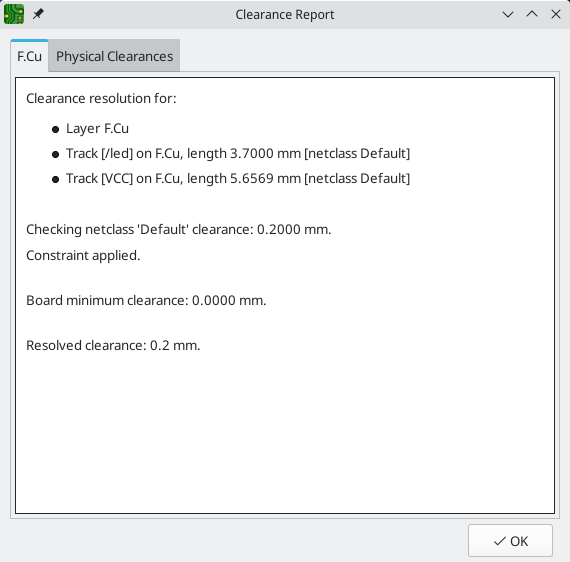

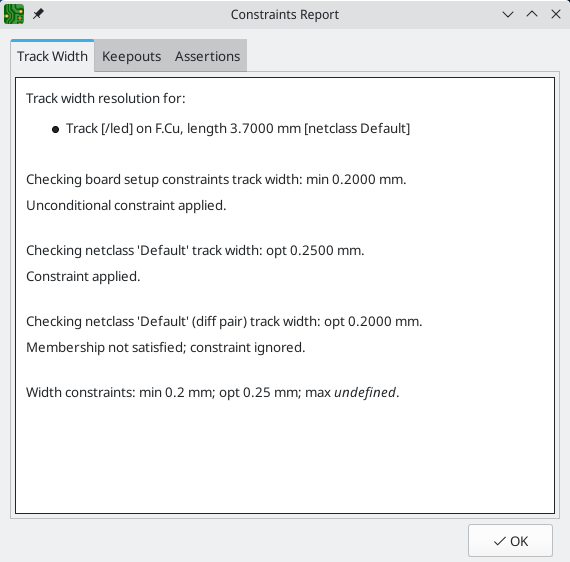

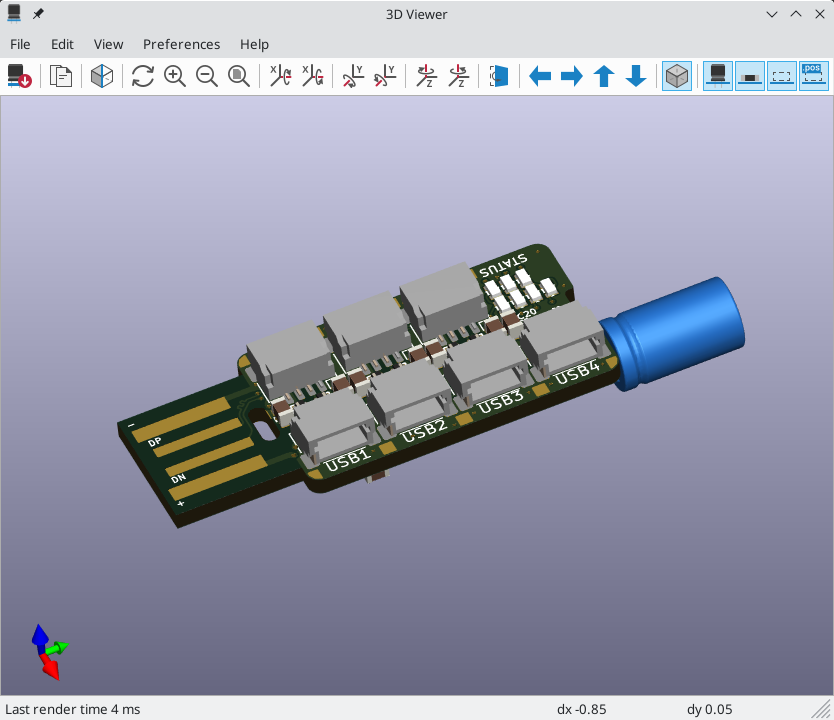

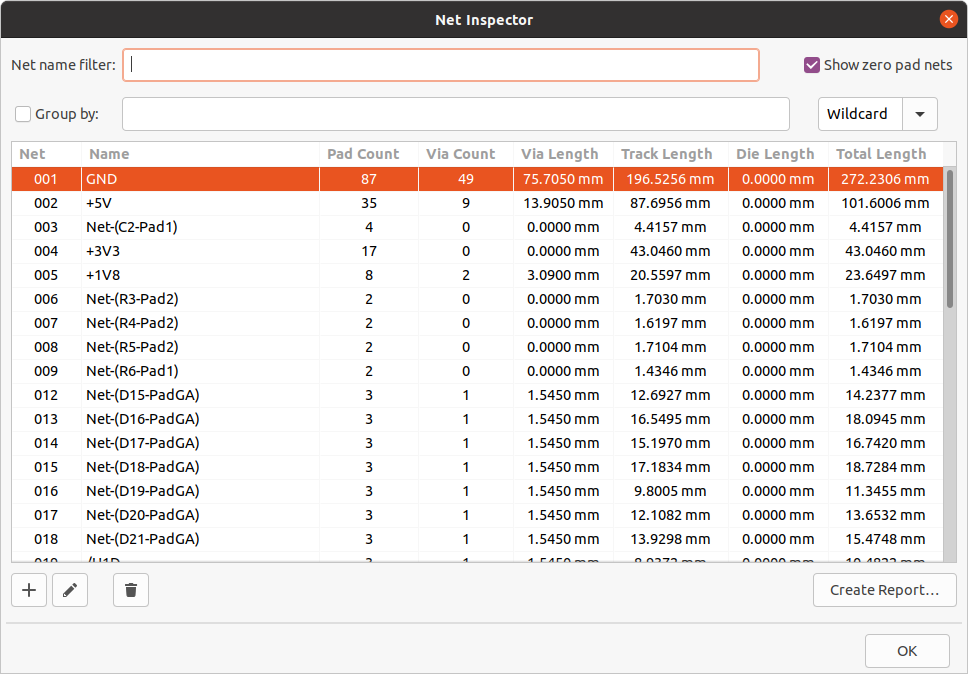

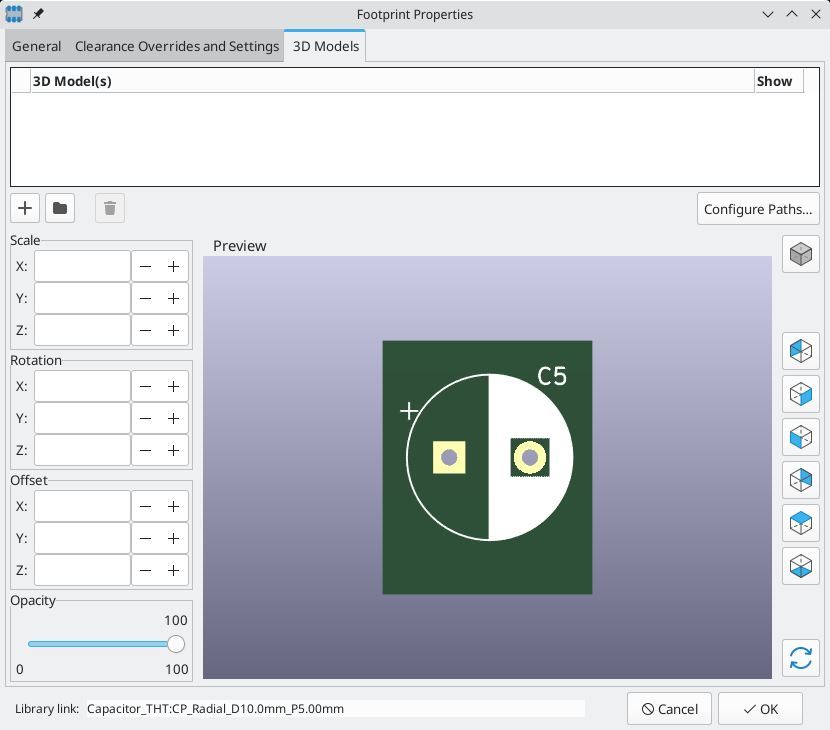

Which mode to use is a matter of preference. For most users, we recommend using Shove mode for the most efficient routing experience or Walk Around mode if you do not want the router to modify tracks that are not being routed. Note that Shove and Walk Around modes always create horizontal, vertical, and 45-degree (H/V/45) track segments. If you need to route tracks with angles other than H/V/45, you must use Highlight Collisions mode and enable the Free Angle Mode option in the Interactive Router Settings dialog.